Fu#&$n crank pulley!! Please help!!!

#1

Ok so I'm trying to change out my opti. I can't get the freakin pulley off to save my life. I tried the autozone pulley pullers, I've tried hammering, I've tried man handling that bitch off. It's still the stock opti, so my guess is the pulley has never been removed. I'm going home on leave next wednesday amd need to get the car running. Someone please help!!!

#5

Ya I just sprayed it with some PB blaster and I'm gonna let it sit overnight.

I tried the 3 jaw puller, and another puller. I tried a hard mallet, and I tried a regular hammer. I tried jist yanking on it. Nothing I did worked. Hopefully the pb blaster will help. I'm about to just say screw it and pull the motor to start my LS swap. Haha

I tried the 3 jaw puller, and another puller. I tried a hard mallet, and I tried a regular hammer. I tried jist yanking on it. Nothing I did worked. Hopefully the pb blaster will help. I'm about to just say screw it and pull the motor to start my LS swap. Haha

#6

Ya I just sprayed it with some PB blaster and I'm gonna let it sit overnight.

I tried the 3 jaw puller, and another puller. I tried a hard mallet, and I tried a regular hammer. I tried jist yanking on it. Nothing I did worked. Hopefully the pb blaster will help. I'm about to just say screw it and pull the motor to start my LS swap. Haha

I tried the 3 jaw puller, and another puller. I tried a hard mallet, and I tried a regular hammer. I tried jist yanking on it. Nothing I did worked. Hopefully the pb blaster will help. I'm about to just say screw it and pull the motor to start my LS swap. Haha

#7

If you pull on it straight, it's gonna come off.

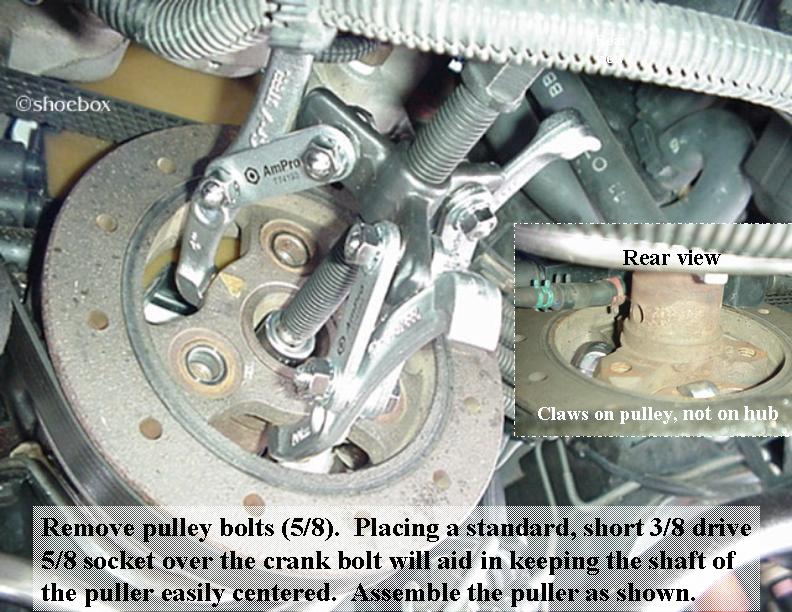

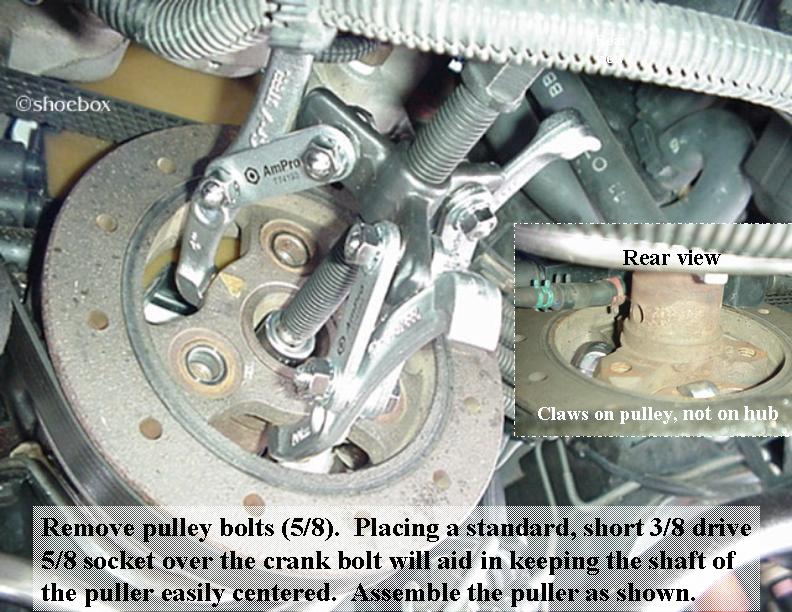

http://shbox.com/1/pull_pulley.jpg

There is no car information given, but if it is a later model pulley, it has holes in it for using a conventional balancer puller.

http://shbox.com/1/engine_front_diagram.jpg

http://shbox.com/1/pull_pulley.jpg

There is no car information given, but if it is a later model pulley, it has holes in it for using a conventional balancer puller.

http://shbox.com/1/engine_front_diagram.jpg

Trending Topics

#8

If you pull on it straight, it's gonna come off.

http://shbox.com/1/pull_pulley.jpg

There is no car information given, but if it is a later model pulley, it has holes in it for using a conventional balancer puller.

http://shbox.com/1/engine_front_diagram.jpg

http://shbox.com/1/pull_pulley.jpg

There is no car information given, but if it is a later model pulley, it has holes in it for using a conventional balancer puller.

http://shbox.com/1/engine_front_diagram.jpg

#10

Let's clarify something here:

Are you trying to remove the pulley off the hub leaving the hub on the crank

OR

Are you trying to remove the pulley AND hub off the crank like it was a single piece old school small block Chevy balancer?

Are you trying to remove the pulley off the hub leaving the hub on the crank

OR

Are you trying to remove the pulley AND hub off the crank like it was a single piece old school small block Chevy balancer?

#11

Trying to remove the pulley. I'm replacing the opti, and all the write ups I see just say remove the pulley, but some pictures look like just the pulley, and other look like the pulley amd the hub. I just need enough room to replace the opti. But I can't break the pulley loose. No movement out of it, whatsoever.

#12

Three bolts hold the pulley to the hub. After that, you'll need to pull it off like old school SBC but the center point of your puller should be pushing on the hub bolt into the crank.

This will leave the hub on the crank.

The pulley is just a press fit onto the hub.

This will leave the hub on the crank.

The pulley is just a press fit onto the hub.

#13

I tried two different pullers. The stud for both pullers just spun around on the center bolt. I haven't tried sticking a socket over the center bolt amd trying the puller that way. I'll try again tomorrow when I have better lighting. Haha

#14

No offense but it honestly sounds to me like you're not familiar with how a puller works. The center stud is supposed to spin - that's why you use a socket, so it doesn't gall up the bolt and keep the screw centered.

Many times it takes a good amount of force - perhaps more than you think. But the LAST thing you want to do is beat on it with a hammer. You need a good puller, lots of PB Blaster, and even leverage on the forcing screw. An impact gun works wonders on forcing screws. You also have to make absolutely sure the claws of the puller are on the pulley and not the hub. Check the shbox.com link in case you haven't already (I see you're on a cell phone):

Many times it takes a good amount of force - perhaps more than you think. But the LAST thing you want to do is beat on it with a hammer. You need a good puller, lots of PB Blaster, and even leverage on the forcing screw. An impact gun works wonders on forcing screws. You also have to make absolutely sure the claws of the puller are on the pulley and not the hub. Check the shbox.com link in case you haven't already (I see you're on a cell phone):

#15

That's how I had it. I tried again this morning, nothing. I couldn't tell last night, but the threads on the forcing bolt are pretty worn down. I'm gonna see if they have another one I can rent out.

#17

I always removed them as one piece by loosening the center bolt, thread it in a few rotations then used that as the pullers leverage point. Let us know how it goes!

#18

Good news!!! I used the new puller they gave me. Used the short socket as a guide for the forcing bolt. In guessing the problem was the bad threads on the old one cause this one pulled it right out. My bad guys. Haha

#19

Gently run some emory cloth around on the ID hole of the balancer before reinstall. I did this on my ASP pulley and I can actually seat it by hand and it comes off with ease the next time.

#20

http://members.***.net/gmarengo/Misc/Misc.htm

http://members.***.net/gmarengo/Misc..._assembled.JPG

Here's mine in action:

EDIT: the links seem to be broken... thread the rod all the way in, put some big washers on, put a nut all the way down against th washers. put 2 on the rod somewhere behind the 1st (closer to the hub is easier) and turn them opposing so they bind slightly against each other. Turn the nut against the washers ("#1") clockwise and middle one ("#2") counterclockwise at the same time. Pushes the hub on instead of pulling it on with the crank threads.

Last edited by Gojira94; 10-11-2013 at 09:41 AM. Reason: Broken URLs