Does YOUR Clutch Setup need a Shim?

#101

FormerVendor

iTrader: (38)

Join Date: Nov 2008

Location: Pearland, TX

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

Update: I got the right flywheel and its a SLP standard weight and everything is good as far as a gap is concerned. Its .050 gap with new throw out bearing and the old shot one measures .072 gap so I'm assuming it'll break in and be perfect.

I got it all back together and the clutch engages right off the floor and its hard to shift so basically the clutch is not disengaging.... what do I do? or what is wrong? i bled it over and over and pedal still feels the same.

LSTUD what end up happening???? anyone help me please!

I got it all back together and the clutch engages right off the floor and its hard to shift so basically the clutch is not disengaging.... what do I do? or what is wrong? i bled it over and over and pedal still feels the same.

LSTUD what end up happening???? anyone help me please!

Well, I believe your measurements are wrong...especially teh tob to face of tranny one..you came up with, what 2.3xx"??

That would be BY FAR teh longest slave I have ever seen/heard of. The longest one I have measured has been @ 2.1xx, so you are talking about a slave that is @ .250 longer than any slave I have seen.

Take pics of how you measured, or go to my thread below and see actual pics of how to measure...

https://ls1tech.com/forums/manual-tr...good-tech.html

#102

FormerVendor

iTrader: (38)

Join Date: Nov 2008

Location: Pearland, TX

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

Update: I got the right flywheel and its a SLP standard weight and everything is good as far as a gap is concerned. Its .050 gap with new throw out bearing and the old shot one measures .072 gap so I'm assuming it'll break in and be perfect.

I got it all back together and the clutch engages right off the floor and its hard to shift so basically the clutch is not disengaging.... what do I do? or what is wrong? i bled it over and over and pedal still feels the same.

LSTUD what end up happening???? anyone help me please!

I got it all back together and the clutch engages right off the floor and its hard to shift so basically the clutch is not disengaging.... what do I do? or what is wrong? i bled it over and over and pedal still feels the same.

LSTUD what end up happening???? anyone help me please!

Also, with .050, that is TIGHT, and you would THINK that as soon as you begin to push in pedal, that it would start to disengage...

tell me this...where does your clutch pedal sit...below, at, or above teh brake pedal???

#103

TECH Regular

iTrader: (1)

Join Date: May 2008

Location: Iowa

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

Hey Gen414, yep the pics are exactly how i measured it. I would totally agree about the gap as well the smaller the gap the better it should disengage. I will check my pedal location compared to the brake pedal tomorrow night.

Here's the latest, i drove the car a bit Saturday and i bleed it a couple more times and no change with the disengagement. Oh and it does drag a little bit doing the rev test so i parked it cuz i don't want to wear out the new clutch. i ordered the Tick adjustable master cylinder and they said it will fix my problem.

One thing i thought of is the pedal is damn hard to push in once the "dead space" is gone aka when its actually moving the pressure plate. i'm assuming this is normal for being such a stiff clutch but i'm worried that with the Tick MC that it will add 15% pedal pressure i won't be able to work the clutch without steroids.....

And i didn't mention this before but the car has a vibration from 2-3000rpm now and its not tranny or rearend related. but does seem to be magnified when moving. You can sit still and rev it and it vibrates like crazy but smooths out after 3k...... what the hell is that? i'm assuming its the clutch or flywheel out of balance? What now? Everything is aligned right using the dowels and torqued right...... i'm just hoping that everything will be fixed once i get the new master cylinder.

Here's the latest, i drove the car a bit Saturday and i bleed it a couple more times and no change with the disengagement. Oh and it does drag a little bit doing the rev test so i parked it cuz i don't want to wear out the new clutch. i ordered the Tick adjustable master cylinder and they said it will fix my problem.

One thing i thought of is the pedal is damn hard to push in once the "dead space" is gone aka when its actually moving the pressure plate. i'm assuming this is normal for being such a stiff clutch but i'm worried that with the Tick MC that it will add 15% pedal pressure i won't be able to work the clutch without steroids.....

And i didn't mention this before but the car has a vibration from 2-3000rpm now and its not tranny or rearend related. but does seem to be magnified when moving. You can sit still and rev it and it vibrates like crazy but smooths out after 3k...... what the hell is that? i'm assuming its the clutch or flywheel out of balance? What now? Everything is aligned right using the dowels and torqued right...... i'm just hoping that everything will be fixed once i get the new master cylinder.

#104

FormerVendor

iTrader: (38)

Join Date: Nov 2008

Location: Pearland, TX

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

Hey Gen414, yep the pics are exactly how i measured it. I would totally agree about the gap as well the smaller the gap the better it should disengage. I will check my pedal location compared to the brake pedal tomorrow night.

Here's the latest, i drove the car a bit Saturday and i bleed it a couple more times and no change with the disengagement. Oh and it does drag a little bit doing the rev test so i parked it cuz i don't want to wear out the new clutch. i ordered the Tick adjustable master cylinder and they said it will fix my problem.

One thing i thought of is the pedal is damn hard to push in once the "dead space" is gone aka when its actually moving the pressure plate. i'm assuming this is normal for being such a stiff clutch but i'm worried that with the Tick MC that it will add 15% pedal pressure i won't be able to work the clutch without steroids.....

And i didn't mention this before but the car has a vibration from 2-3000rpm now and its not tranny or rearend related. but does seem to be magnified when moving. You can sit still and rev it and it vibrates like crazy but smooths out after 3k...... what the hell is that? i'm assuming its the clutch or flywheel out of balance? What now? Everything is aligned right using the dowels and torqued right...... i'm just hoping that everything will be fixed once i get the new master cylinder.

Here's the latest, i drove the car a bit Saturday and i bleed it a couple more times and no change with the disengagement. Oh and it does drag a little bit doing the rev test so i parked it cuz i don't want to wear out the new clutch. i ordered the Tick adjustable master cylinder and they said it will fix my problem.

One thing i thought of is the pedal is damn hard to push in once the "dead space" is gone aka when its actually moving the pressure plate. i'm assuming this is normal for being such a stiff clutch but i'm worried that with the Tick MC that it will add 15% pedal pressure i won't be able to work the clutch without steroids.....

And i didn't mention this before but the car has a vibration from 2-3000rpm now and its not tranny or rearend related. but does seem to be magnified when moving. You can sit still and rev it and it vibrates like crazy but smooths out after 3k...... what the hell is that? i'm assuming its the clutch or flywheel out of balance? What now? Everything is aligned right using the dowels and torqued right...... i'm just hoping that everything will be fixed once i get the new master cylinder.

So as to not add to this thread any

...do you have a thread started? If not, start one, so we can take it up there...

...do you have a thread started? If not, start one, so we can take it up there...

#105

On The Tree

Join Date: Jul 2004

Location: Tulsa, Ok.

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

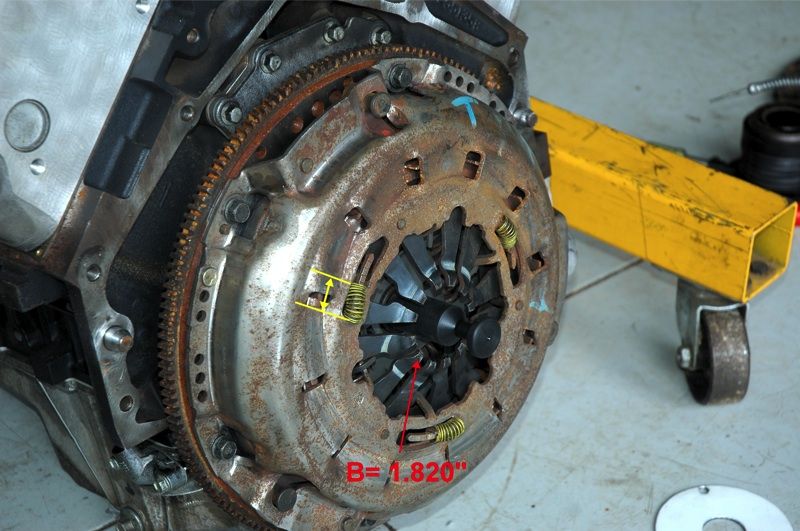

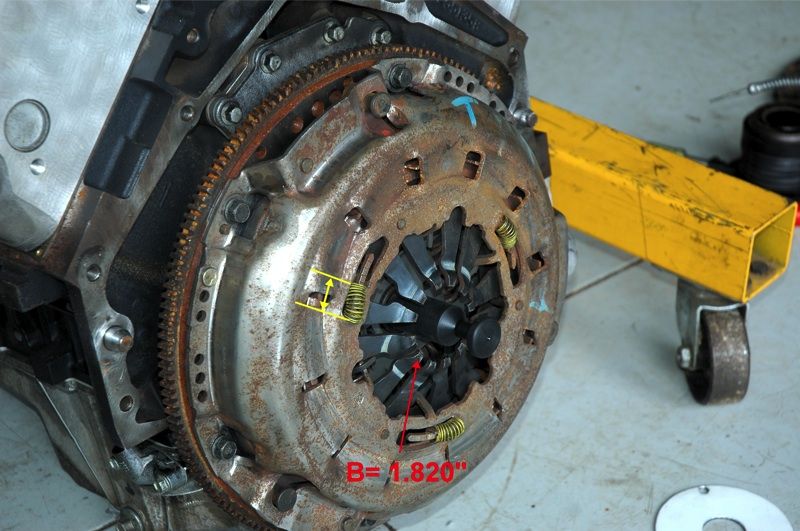

"If there is no difference between the two measurements, or if "B" is greater than "A", there could be a problem with clutch engagement which could result in premature clutch slip and eventually a total failure."

So, I have a new clutch, a new slave, and resurfaced flywheel. My "B" is greater than my "A" by a good 1/8th an inch. What the heck does one do with that?

So, I have a new clutch, a new slave, and resurfaced flywheel. My "B" is greater than my "A" by a good 1/8th an inch. What the heck does one do with that?

#106

I'm TTT, but more to tag for my own benefit. I'm doing an LS- tranny up to a sbc. I got the Quicktime adapter bellhousing, the Rhino TO bearing, and the guy that sold me the package used has been a good sport and recently replied back to me, "You saw the .125 spacer already added under the TO bearing right?" I'm like, "TO spacer?" Then he said, "You bought the sbc flywheel spacer required to shift the PP aft going from sbc to LS- tranny, right?" I'm again like, "flywheel spacer?"  lol

lol

I realize much of this does not apply to LS- motor guys here, but this overall site has been real valuable for intel on my install into my son's '88 Monte. And now this shimming detail. At least now I'll ->APPEAR smart when we finally get to the install eh. Sorry for the hyjack.

lol

lolI realize much of this does not apply to LS- motor guys here, but this overall site has been real valuable for intel on my install into my son's '88 Monte. And now this shimming detail. At least now I'll ->APPEAR smart when we finally get to the install eh. Sorry for the hyjack.

#107

Launching!

iTrader: (14)

Regarding the OE pressure plates that are adjustable, Self Adjusting Cover/clutch, (SAC) it was mentioned elsewhere, this thread or the other picture thread, and thought it might be worth while to cover a little more in-depth for those running the SAC, vs shimming.

My knowledge on this limited other than what I’ve uncovered through Google research since last night and running my pressure plate through the adjustment range and seeing the results first hand, so if any of the Clutch experts want to correct any of my mistakes, fill in missing hole’s etc, please do so.

Yesterday I ran into an issue where my new Tick performance slave cylinder was bottomed out and holding my clutch disengaged, pushing in on the PP fingers over ¼” an inch, i.e. -.270” between my “A” and “B” measurements. I knew the issue wasn’t the slave as it measured up similarly to 2 other used slaves I have laying around when they are fully compressed/bottomed per the "How To" in the first post, so it had be my clutch. Thankfully I found this thread and the other Picture version thread along the PDF linked below on how to adjust those OE style SAC's. After seeing how this works and playing with the adjustment on the press and my engine, I realized it probably wouldn’t have been an issue to just leave it as it is self adjusting once the clamping pressure is released on the disc as the fingers are pushed further, i.e. clutch actuated?

How to adjust the SAC;

http://paceperformance.com/files/pdf/zo6clutchadj.pdf

I ran the adjuster on my PP through its range and here are the results with "B" measurements, (bell housing was removed for the pics). Note that it is adjustable beyond both extremes of the slave travel, as such no shim is required with these clutches, though it should automatically compensate if you did install one for what-ever reason.

My knowledge on this limited other than what I’ve uncovered through Google research since last night and running my pressure plate through the adjustment range and seeing the results first hand, so if any of the Clutch experts want to correct any of my mistakes, fill in missing hole’s etc, please do so.

Yesterday I ran into an issue where my new Tick performance slave cylinder was bottomed out and holding my clutch disengaged, pushing in on the PP fingers over ¼” an inch, i.e. -.270” between my “A” and “B” measurements. I knew the issue wasn’t the slave as it measured up similarly to 2 other used slaves I have laying around when they are fully compressed/bottomed per the "How To" in the first post, so it had be my clutch. Thankfully I found this thread and the other Picture version thread along the PDF linked below on how to adjust those OE style SAC's. After seeing how this works and playing with the adjustment on the press and my engine, I realized it probably wouldn’t have been an issue to just leave it as it is self adjusting once the clamping pressure is released on the disc as the fingers are pushed further, i.e. clutch actuated?

How to adjust the SAC;

http://paceperformance.com/files/pdf/zo6clutchadj.pdf

I ran the adjuster on my PP through its range and here are the results with "B" measurements, (bell housing was removed for the pics). Note that it is adjustable beyond both extremes of the slave travel, as such no shim is required with these clutches, though it should automatically compensate if you did install one for what-ever reason.

Last edited by BRAAPZ; 11-01-2010 at 10:56 AM.

#108

Wow I am glad I came across this before I installed my 6 speed. I am doing a ls t56 behind an 8.1 in my truck. And I think post # 91 is very relevant. especially with the after market throw out bearings available etc

#109

TECH Enthusiast

Join Date: Jun 2006

Location: Enid, OK

Posts: 594

Likes: 0

Received 0 Likes

on

0 Posts

I just received my RAM twin, my measuring instructions say to measure from bearing face to transmission face for B. But doesnt show the bearing pressed to the base. Also the dimension B is to be .600-.700 longer then A, im guessing its cuz the measurement isnt taken with the slave compressed? and its a twin

#110

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

I would do it compressed or at least measure the compression of the slave first so you know it's travel. If it's calling for .600 to .700", then yes that would be because they are having you measure from the extended position.

#114

anyone now what the dimension is from the tob to the slave mount compressed, basically if you unbolted it and laid it flat on a table compress or pushed all the way done on it, what would it be? Is that dimension different from a SSR, GTO, F-body? also what is the measure meant from the clutch fingers to the crankshaft recess, the the hole where the pilot goes but the one that is flush with the face of the pilot bearing. Thanks

#115

Staging Lane

iTrader: (8)

Join Date: Jun 2006

Location: NE TEXAS

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

I had a monster 5 clutch. I pulled it apart when i had TDp upgrade my tranny. I went ahead and pulled the clutch out of it to check the condition of it. It was worn(.040+) almost to the rivots. I wasnt planning on buying a clutch right then, so i had to step down and buy a level 3(without flywheel). I turned my flywheel(machine shop said it was warped .040). Monster said if u go over .020" then u might need a shim. So i had a shim made .037 thick. Now i have been driving around and the clutch is right on top of the pedal.(i think to much shim). I have adjusted my tick MC but still on top. I thinking about sliding the tranny back out and pulling the shim out. While i am there i will take those measurements.

With the pedal on top does that sound like the shim is to thick?

How many miles usually is recommended for breaking in a clutch?

Theres a stroked mustang that i need to shut his mouth.

Thanks

With the pedal on top does that sound like the shim is to thick?

How many miles usually is recommended for breaking in a clutch?

Theres a stroked mustang that i need to shut his mouth.

Thanks

#116

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

500 miles of good stop and go with lots of heat cycles. If the disengagement point is at the top, then yes, to much shim. I would let the clutch fully break in though before you pull the shim. Generally the most clutch material is lost during the break in process. Also, as you mentioned, measure everything when you pull it apart. That will tell you how much shim you need for a good pedal.

#117

I may need to shim 3/4" to 1" is that possible how thick are the shims that are available and how many can you stack? What about a shim that goes between the mounting bolts, to the front of the trans?

#118

Will this affect the amount of clamping force on the disk? What dimension was it from the factory? Some where in the middle? Where are you measuring from? The counter bore in the crank, that is flush with the pilot bearing to the clutch fingers?

do you know what the height of the slave cylinder is fully compressed, and fully extended?

do you know what the height of the slave cylinder is fully compressed, and fully extended?

Regarding the OE pressure plates that are adjustable, Self Adjusting Cover/clutch, (SAC) it was mentioned elsewhere, this thread or the other picture thread, and thought it might be worth while to cover a little more in-depth for those running the SAC, vs shimming.

My knowledge on this limited other than what I’ve uncovered through Google research since last night and running my pressure plate through the adjustment range and seeing the results first hand, so if any of the Clutch experts want to correct any of my mistakes, fill in missing hole’s etc, please do so.

Yesterday I ran into an issue where my new Tick performance slave cylinder was bottomed out and holding my clutch disengaged, pushing in on the PP fingers over ¼” an inch, i.e. -.270” between my “A” and “B” measurements. I knew the issue wasn’t the slave as it measured up similarly to 2 other used slaves I have laying around when they are fully compressed/bottomed per the "How To" in the first post, so it had be my clutch. Thankfully I found this thread and the other Picture version thread along the PDF linked below on how to adjust those OE style SAC's. After seeing how this works and playing with the adjustment on the press and my engine, I realized it probably wouldn’t have been an issue to just leave it as it is self adjusting once the clamping pressure is released on the disc as the fingers are pushed further, i.e. clutch actuated?

How to adjust the SAC;

http://paceperformance.com/paceperfo...6ClutchAdj.pdf

I ran the adjuster on my PP through its range and here are the results with "B" measurements, (bell housing was removed for the pics). Note that it is adjustable beyond both extremes of the slave travel, as such no shim is required with these clutches, though it should automatically compensate if you did install one for what-ever reason.

My knowledge on this limited other than what I’ve uncovered through Google research since last night and running my pressure plate through the adjustment range and seeing the results first hand, so if any of the Clutch experts want to correct any of my mistakes, fill in missing hole’s etc, please do so.

Yesterday I ran into an issue where my new Tick performance slave cylinder was bottomed out and holding my clutch disengaged, pushing in on the PP fingers over ¼” an inch, i.e. -.270” between my “A” and “B” measurements. I knew the issue wasn’t the slave as it measured up similarly to 2 other used slaves I have laying around when they are fully compressed/bottomed per the "How To" in the first post, so it had be my clutch. Thankfully I found this thread and the other Picture version thread along the PDF linked below on how to adjust those OE style SAC's. After seeing how this works and playing with the adjustment on the press and my engine, I realized it probably wouldn’t have been an issue to just leave it as it is self adjusting once the clamping pressure is released on the disc as the fingers are pushed further, i.e. clutch actuated?

How to adjust the SAC;

http://paceperformance.com/paceperfo...6ClutchAdj.pdf

I ran the adjuster on my PP through its range and here are the results with "B" measurements, (bell housing was removed for the pics). Note that it is adjustable beyond both extremes of the slave travel, as such no shim is required with these clutches, though it should automatically compensate if you did install one for what-ever reason.

#119

Staging Lane

iTrader: (1)

Join Date: Oct 2002

Location: Wisconsin

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Ok, I have been having some clutch issues. I could bleed my clutch and it would work great for about a week with engagement at the top of the pedal throw, and then about a week later my pedal will sink lower and lower until the clutch will hardly disengage. It only takes about 2 stoplights for this to happen once the clutch starts to drop. If I bleed the system the clutch would go back to normal, with no bubbles coming out of the fluid while bleeding.

Oh, my setup is stock LS7 clutch, and a 7/8 wilwood master cylinder, and remote bleeder in an RX7.

I didn't think it was a shim problem not but I figured I would measure my clearences while I had my trans out to check for leaks at the slave. With my new slave my measurement came out to .327", which according to Tick in this thread calls for a shim.

I decided to measure my old slave and while attempting a measurement I noticed the slave wouldn't even bottom out all the way like the new one, here is a pic to illustrate.

This shows the NEW slave compressed completly to the bottom. The old slave will NOT compress that far, infact it only compresses at a max to about 1/4" from the bottom.

So what is normal? Should the slave bottom out completly or not? I've been told maybe I over-extended the slave and damaged a seal inside and maybe that is causing my old slave to not bottom out all the way?

I've played with alot of clutches in my professional career, but no problems ever like this.

Oh, my setup is stock LS7 clutch, and a 7/8 wilwood master cylinder, and remote bleeder in an RX7.

I didn't think it was a shim problem not but I figured I would measure my clearences while I had my trans out to check for leaks at the slave. With my new slave my measurement came out to .327", which according to Tick in this thread calls for a shim.

I decided to measure my old slave and while attempting a measurement I noticed the slave wouldn't even bottom out all the way like the new one, here is a pic to illustrate.

This shows the NEW slave compressed completly to the bottom. The old slave will NOT compress that far, infact it only compresses at a max to about 1/4" from the bottom.

So what is normal? Should the slave bottom out completly or not? I've been told maybe I over-extended the slave and damaged a seal inside and maybe that is causing my old slave to not bottom out all the way?

I've played with alot of clutches in my professional career, but no problems ever like this.

Last edited by SoonLS1Powered; 09-09-2010 at 08:02 PM.

#120

dude, your picture is too big, your causing bandwith pollution and making me have to scroll to the right on my laptop. do you see any drips of fluid or is your brake reservoir going down?

Last edited by unclebens; 09-09-2010 at 08:07 PM.