The last inch

#1

I put in a new Monster LT1-S and have spent hours and hours trying to get the trans fully seated against the bellhousing. I've taken it down a few times to make sure the plastic alignment tool still goes in and out (and it does). The first hang up was about 1.5" out but some wiggling around got it to come up .75" all at once. Then after much struggling I decided to put some upward pressure on the front of the engine and was able to get it where it now it sits, 7/16" away.

I have read that the last .5" is the hardest, but that it will eventually just pop in. With me underneath the car pushing and wiggling, and a helper pulling from the front of the car with a strap around the back of the trans, we just can not get it in. It is close enough now where the bolts will thread in. I have heard of a method where you would connect the hydraulics and push in the clutch and then try to get everything aligned. Also with just a nut driver I think I could maybe use the bolts to suck the trans up. I would go slow by hand (no ratchet) and evenly from side to side, but I have read that is a no-no in general. My only other option is to drop it down, try realigning - possibly with a steel alignment tool. It would be sad to lose all the progress I've made and have to take the bellhousing off again, but I don't want to ruin the pilot and have even more re-work.

Any recommendations other than just keep trying? Has anyone had success by pressing in the clutch peddle? Will the pilot bearing be ruined if I pull it on with the bolts (and hand nut driver, not a ratchet)? Or just drop it back down, and get a steel alignment tool and re-start?

Thanks!

I have read that the last .5" is the hardest, but that it will eventually just pop in. With me underneath the car pushing and wiggling, and a helper pulling from the front of the car with a strap around the back of the trans, we just can not get it in. It is close enough now where the bolts will thread in. I have heard of a method where you would connect the hydraulics and push in the clutch and then try to get everything aligned. Also with just a nut driver I think I could maybe use the bolts to suck the trans up. I would go slow by hand (no ratchet) and evenly from side to side, but I have read that is a no-no in general. My only other option is to drop it down, try realigning - possibly with a steel alignment tool. It would be sad to lose all the progress I've made and have to take the bellhousing off again, but I don't want to ruin the pilot and have even more re-work.

Any recommendations other than just keep trying? Has anyone had success by pressing in the clutch peddle? Will the pilot bearing be ruined if I pull it on with the bolts (and hand nut driver, not a ratchet)? Or just drop it back down, and get a steel alignment tool and re-start?

Thanks!

#3

DO NOT pull trans in with bolts. You will kill the pilot doing so

The discs are not dead nuts lined up. Yeah we have all been there because of this and it is frustrating, especially with multi disc clutches

What I found that helps is with the alignment tool holding in everything don't just let the discs hang on the spline tool. Hold it straight in with your hand as you tighten a few of the PP bolts enough to hold everything. The weight of the discs drags the spline ool down some so when you go to stab the tranny the input shaft does go through the disc splines but because they are not dead nuts centered the input shaft tip is catching the side of the pilot bearing. Put forward force on the spline tool while tightening the PP bolts enough the hold everything

Also run your fingers around clutch/PP edge to feel if = all the way around the outer edges of discs. If one side feels slightly over vs the other..it is not centered

and when putting tranny in to BH make sure angle of approach is = to angle of BH. Meaning if 1" away is that distance the same top & bottom & side to side...it needs to be. Using a floor jack under motor can help lift the motor some if needed. Also having a tranny jack greatly helps. My Harbor Freight $50 tranny jack is worth every penny IMHO

If the tranny is 1" away you won't get the slave to release the clutch enough to get the disc to move enough to get tranny in. That worked back when there was mechanical clutch linkage

The discs are not dead nuts lined up. Yeah we have all been there because of this and it is frustrating, especially with multi disc clutches

What I found that helps is with the alignment tool holding in everything don't just let the discs hang on the spline tool. Hold it straight in with your hand as you tighten a few of the PP bolts enough to hold everything. The weight of the discs drags the spline ool down some so when you go to stab the tranny the input shaft does go through the disc splines but because they are not dead nuts centered the input shaft tip is catching the side of the pilot bearing. Put forward force on the spline tool while tightening the PP bolts enough the hold everything

Also run your fingers around clutch/PP edge to feel if = all the way around the outer edges of discs. If one side feels slightly over vs the other..it is not centered

and when putting tranny in to BH make sure angle of approach is = to angle of BH. Meaning if 1" away is that distance the same top & bottom & side to side...it needs to be. Using a floor jack under motor can help lift the motor some if needed. Also having a tranny jack greatly helps. My Harbor Freight $50 tranny jack is worth every penny IMHO

If the tranny is 1" away you won't get the slave to release the clutch enough to get the disc to move enough to get tranny in. That worked back when there was mechanical clutch linkage

#4

The factory T56, the car is a 2001 firebird. Pilot is whatever monster supplied with the clutch. I was dumb and didn't test fit it on the input shaft before putting it in..

I believe with the LT1-S that there is just 1 hub vs 2 separate ones. The trans is only 7/16" away (equal top to bottom) if that makes any difference for trying the trick with pushing the clutch in.

I borrowed a trans jack but unfortunately the car isn't high enough in the air to utilize it, I would have to get taller jack stands.

DO NOT pull trans in with bolts. You will kill the pilot doing so

The discs are not dead nuts lined up. Yeah we have all been there because of this and it is frustrating, especially with multi disc clutches

What I found that helps is with the alignment tool holding in everything don't just let the discs hang on the spline tool. Hold it straight in with your hand as you tighten a few of the PP bolts enough to hold everything. The weight of the discs drags the spline ool down some so when you go to stab the tranny the input shaft does go through the disc splines but because they are not dead nuts centered the input shaft tip is catching the side of the pilot bearing. Put forward force on the spline tool while tightening the PP bolts enough the hold everything

Also run your fingers around clutch/PP edge to feel if = all the way around the outer edges of discs. If one side feels slightly over vs the other..it is not centered

and when putting tranny in to BH make sure angle of approach is = to angle of BH. Meaning if 1" away is that distance the same top & bottom & side to side...it needs to be. Using a floor jack under motor can help lift the motor some if needed. Also having a tranny jack greatly helps. My Harbor Freight $50 tranny jack is worth every penny IMHO

If the tranny is 1" away you won't get the slave to release the clutch enough to get the disc to move enough to get tranny in. That worked back when there was mechanical clutch linkage

The discs are not dead nuts lined up. Yeah we have all been there because of this and it is frustrating, especially with multi disc clutches

What I found that helps is with the alignment tool holding in everything don't just let the discs hang on the spline tool. Hold it straight in with your hand as you tighten a few of the PP bolts enough to hold everything. The weight of the discs drags the spline ool down some so when you go to stab the tranny the input shaft does go through the disc splines but because they are not dead nuts centered the input shaft tip is catching the side of the pilot bearing. Put forward force on the spline tool while tightening the PP bolts enough the hold everything

Also run your fingers around clutch/PP edge to feel if = all the way around the outer edges of discs. If one side feels slightly over vs the other..it is not centered

and when putting tranny in to BH make sure angle of approach is = to angle of BH. Meaning if 1" away is that distance the same top & bottom & side to side...it needs to be. Using a floor jack under motor can help lift the motor some if needed. Also having a tranny jack greatly helps. My Harbor Freight $50 tranny jack is worth every penny IMHO

If the tranny is 1" away you won't get the slave to release the clutch enough to get the disc to move enough to get tranny in. That worked back when there was mechanical clutch linkage

I borrowed a trans jack but unfortunately the car isn't high enough in the air to utilize it, I would have to get taller jack stands.

#5

if the plastic alignment tool end fits snug in the pilot bearing you put in, that plastic tool is the same size as your input shaft

I thought the LT1 S clutch was a "dual" aka "twin" disc clutch. Either single or Twin disc clutch, same thing/technique on aligning the disc as I mentioned in earlier post

Yeah it takes tall jack stands or stands on solid wood risers to get the car up high enough to use a jack. Sucks humping the tranny up without one

#6

10 Second Club

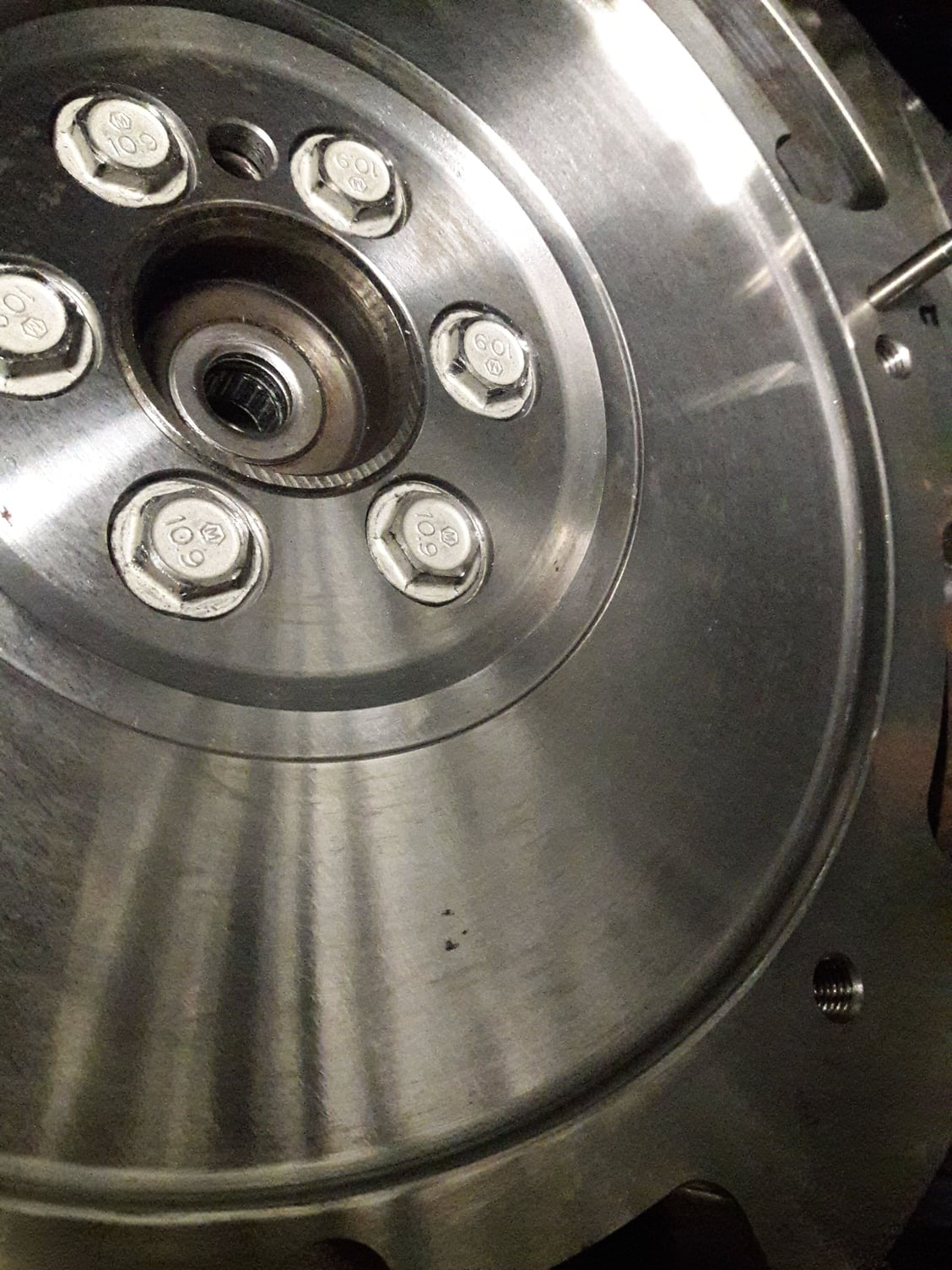

I’m trying to post a pic of which pilot bearing you should have. If it’s the wrong one it will cause this issue. The forum just isn’t cooperating with uploading right now

#7

if the plastic alignment tool end fits snug in the pilot bearing you put in, that plastic tool is the same size as your input shaft

I thought the LT1 S clutch was a "dual" aka "twin" disc clutch. Either single or Twin disc clutch, same thing/technique on aligning the disc as I mentioned in earlier post

Yeah it takes tall jack stands or stands on solid wood risers to get the car up high enough to use a jack. Sucks humping the tranny up without one

I thought the LT1 S clutch was a "dual" aka "twin" disc clutch. Either single or Twin disc clutch, same thing/technique on aligning the disc as I mentioned in earlier post

Yeah it takes tall jack stands or stands on solid wood risers to get the car up high enough to use a jack. Sucks humping the tranny up without one

Trending Topics

#9

9 Second Club

The gearbox should always slide in easily and flush by hand. It should never require excessive effort or to be pulled in by the bolts.

And ensure you have the hydraulic line connected, or the bleeder open to allow the release bearing to retract as you push the trans into the bellhousing.

But it should go very easy, if it doesnt pull it out and find out why

And ensure you have the hydraulic line connected, or the bleeder open to allow the release bearing to retract as you push the trans into the bellhousing.

But it should go very easy, if it doesnt pull it out and find out why

#13

#15

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

I was going to ask if the OP had cracked bleeder. Also, corrosion in the dowel holes will cause resistance. I one had to run a 3/8 carbide bit in the holes to clean them up and it slid right on.

#17

TECH Senior Member

Wouldn't it feel tough pull the trans in with the bolts in if the input shaft was not centered in the pilot bearing - essentially moving the pilot bearing, right?

Also after the trans is installed this way wouldn't the input shaft/pilot bearing be making noise?

Also after the trans is installed this way wouldn't the input shaft/pilot bearing be making noise?

#18

9 Second Club

As said, it should never be necessary. The trans should slide in easily until it is pretty much flush with the BH surface, the only resistance there should be is the spring/release bearing which isnt much at all compared to the weight of the trans.

If it isnt, take it out and find out why.

#20

TECH Senior Member

The sort of person to pull the trans in via the bolts that sort of distance probably wouldnt notice the resistance or damage they might be causing if anything was wrong. But yes, you could be doing all sorts of damage resorting to this.

As said, it should never be necessary. The trans should slide in easily until it is pretty much flush with the BH surface, the only resistance there should be is the spring/release bearing which isnt much at all compared to the weight of the trans.

If it isnt, take it out and find out why.

As said, it should never be necessary. The trans should slide in easily until it is pretty much flush with the BH surface, the only resistance there should be is the spring/release bearing which isnt much at all compared to the weight of the trans.

If it isnt, take it out and find out why.