Powder coat a Fast intake?

#1

Just curious if anybody has powder coated a fast intake. I asked a few powder coaters and they said they haven't done any local and it being a composite material I was just wondering what if anybody has done it and how it has held up.

#2

TECH Addict

iTrader: (7)

Yes you can....I had mine done and it's held up very well. If you can't find anyone local a sponsor here "the powder pro" does them but there in IL.

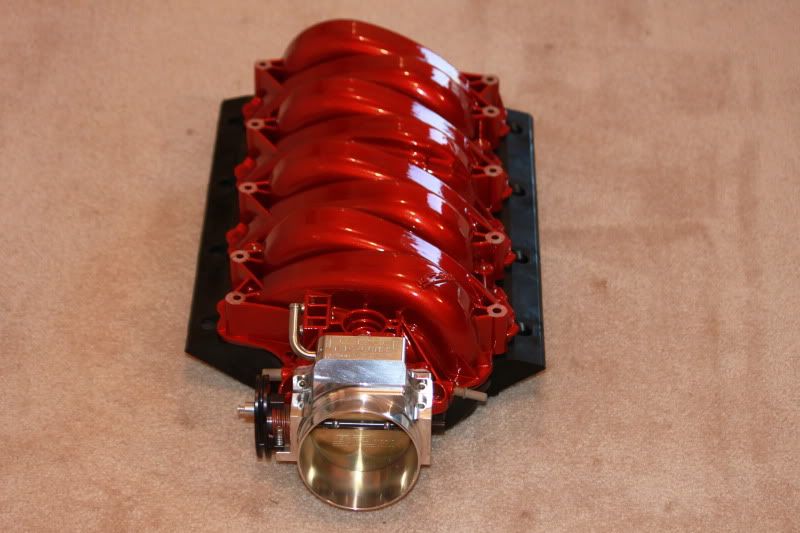

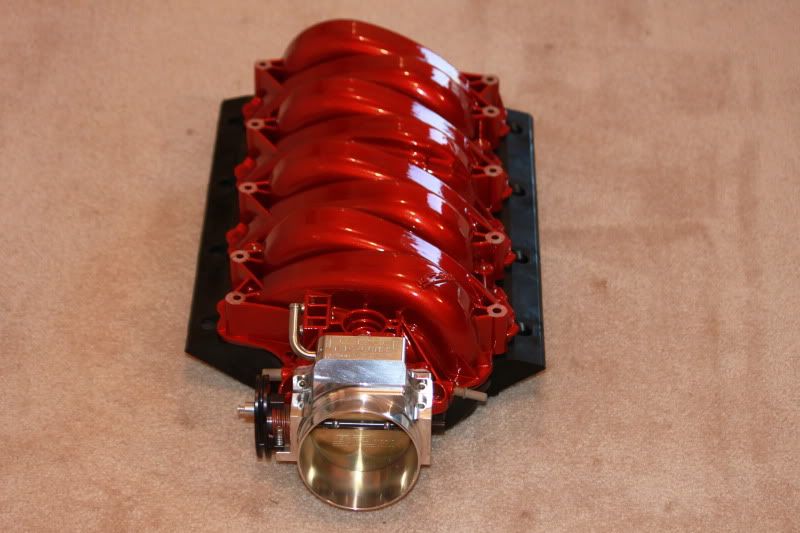

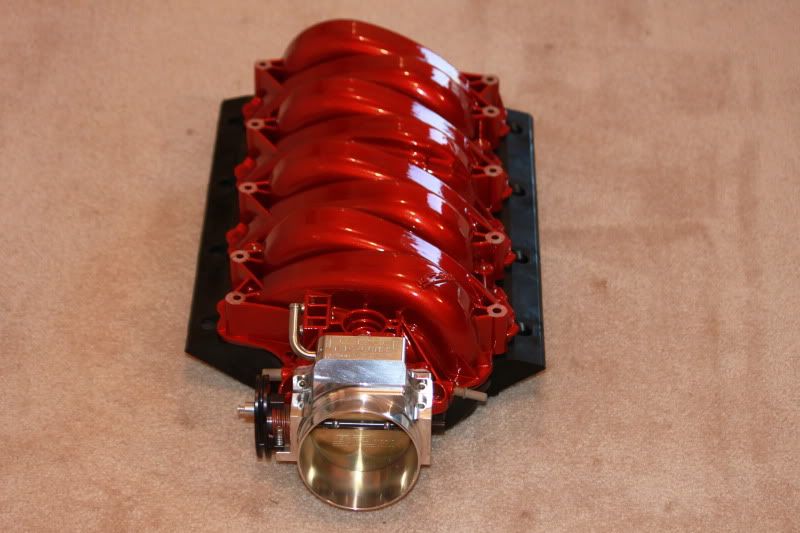

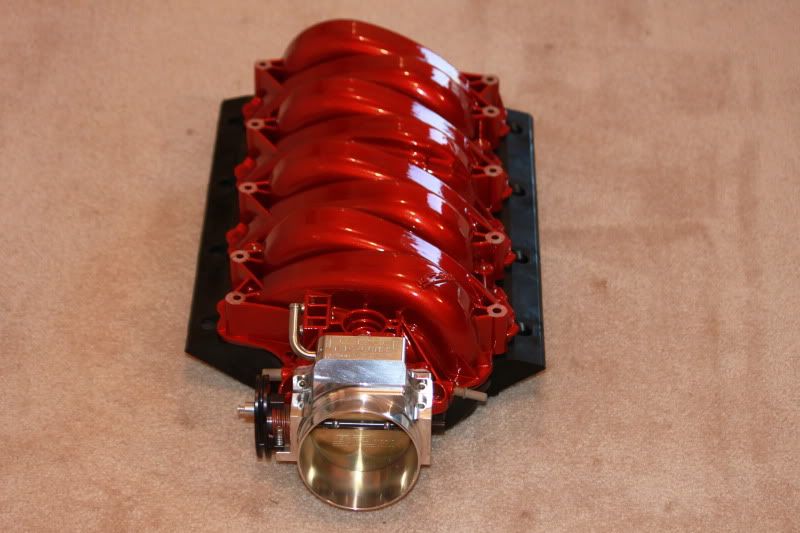

I had mine done SOM....they had a match for it. He'll even shave off the letters if you want at no extra charge. I had them take off the FAST and leave the 92mm.

I had mine done SOM....they had a match for it. He'll even shave off the letters if you want at no extra charge. I had them take off the FAST and leave the 92mm.

#4

Teching In

Join Date: Jun 2009

Location: San Diego Cali, Deer Park Tx

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Yes you can....I had mine done and it's held up very well. If you can't find anyone local a sponsor here "the powder pro" does them but there in IL.

I had mine done SOM....they had a match for it. He'll even shave off the letters if you want at no extra charge. I had them take off the FAST and leave the 92mm.

I had mine done SOM....they had a match for it. He'll even shave off the letters if you want at no extra charge. I had them take off the FAST and leave the 92mm.

#7

Isnt grey with red letter close to its stock appearance?

That red one is.very nice.

Ive seen a couple coated, they look nice.

Also seem debadged and painted flat black

..to look stock intake.

That red one is.very nice.

Ive seen a couple coated, they look nice.

Also seem debadged and painted flat black

..to look stock intake.

Trending Topics

#9

TECH Fanatic

iTrader: (20)

Bumping this up...

PsychoSid and I have done two LS3 intake manifolds that both came out pretty nice. Both of them used powders that required 400DGF cure temps, but we just baked them longer at 375 IIRC. So, I know those will work.

I called FAST to ask if their material was the same as stock. No surprise, the tech said "I have no clue". So while I know we can powder GM manifolds with their MOC, does anyone know what the temp limit is for a FAST upper shell?

PsychoSid and I have done two LS3 intake manifolds that both came out pretty nice. Both of them used powders that required 400DGF cure temps, but we just baked them longer at 375 IIRC. So, I know those will work.

I called FAST to ask if their material was the same as stock. No surprise, the tech said "I have no clue". So while I know we can powder GM manifolds with their MOC, does anyone know what the temp limit is for a FAST upper shell?

#12

TECH Fanatic

iTrader: (20)

But for the fast? Not sure... if I knew it was the same material, piece of cake, 20 min at 375. But I don't know if the fast material has a lower melting point or not. Guess I'llhave to find out the hard way unless someone chimes in!

#14

TECH Veteran

The hydrodipping deal is really cool... I've seen all kind of unique patterns hydrodipped.

#15

Staging Lane

iTrader: (1)

Join Date: Mar 2015

Location: Boston Ma

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

I've been thinking about doing the hydrodip on my 102. Powder would probably last longer but I want it to be as close to chrome as possible. Spectra Chrome is also an option but I'm skeptical about longevity. The last thing I want to do is melt my $1500 Mamo ported intake!

#16

TECH Veteran

I've been thinking about doing the hydrodip on my 102. Powder would probably last longer but I want it to be as close to chrome as possible. Spectra Chrome is also an option but I'm skeptical about longevity. The last thing I want to do is melt my $1500 Mamo ported intake!

I totally understand that!! I've seen all kind of patterns. Skulls, carbon fiber, money, snakeskin.... just to name a few.

#19

TECH Fanatic

iTrader: (20)

A little update, the upper shell showed up and I put it on the back burner. I've taken to making custom Yeti/RTIC/Ozark cups for people, getting progressively more complex. That means more time on cups, less time for car projects.

I think I'm caught up on cup orders, so I've started sanding the shell. Plan is to finish sanding this evening and powder tomorrow. I'm aiming to do "Jack's Blue" with clear, and I'm debating an intermediate coat with a different color for the lettering. Maybe even multiple colors. Depends on where I end up, because I have a hard stop for the Texas game... Hook 'em!

P.S. I have two rules for cups: 1. No Alabama, 2. No OU (sucks)

I think I'm caught up on cup orders, so I've started sanding the shell. Plan is to finish sanding this evening and powder tomorrow. I'm aiming to do "Jack's Blue" with clear, and I'm debating an intermediate coat with a different color for the lettering. Maybe even multiple colors. Depends on where I end up, because I have a hard stop for the Texas game... Hook 'em!

P.S. I have two rules for cups: 1. No Alabama, 2. No OU (sucks)