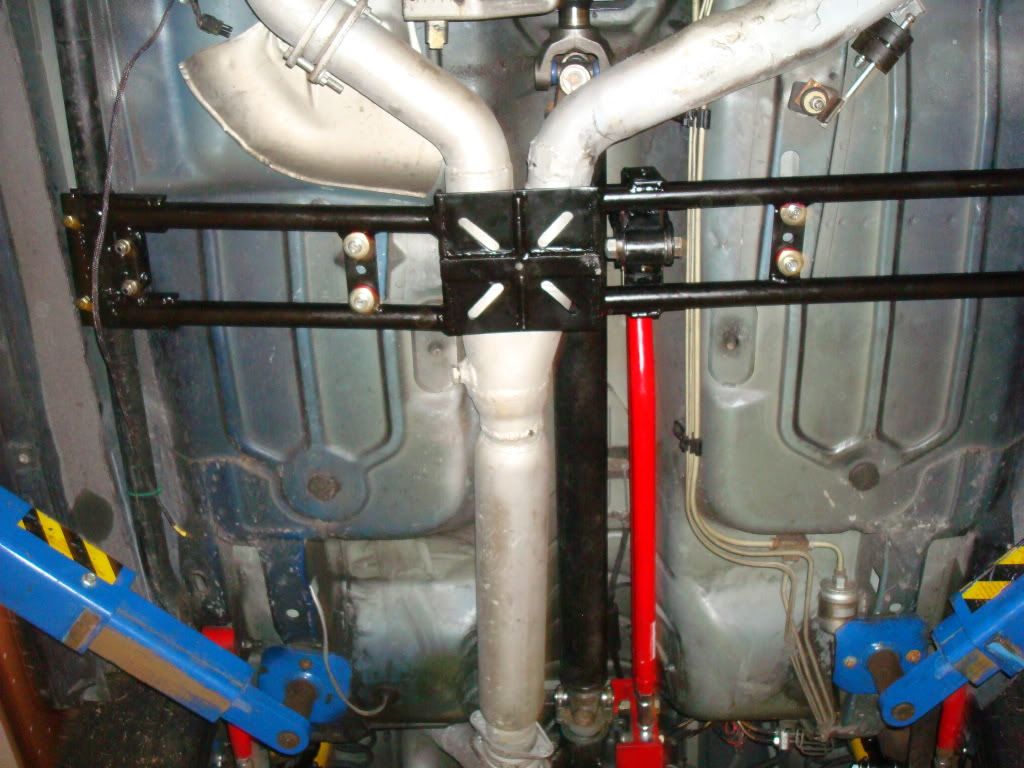

Custom Torque Arm

#1

1) I didn't like the clunk I got going from acceleration to braking.

2) I always dragged my tunnel mount cross brace on speed bumps.

3) I wanted to reduce vibration under my seat for daily driving.

4) Most important was to strengthen the points where the tunnel mount cross member bolted to the car.

5) I did not want to remove my existing welded in subframe connectors.

I made this Torque Arm Cross Member up out of 4130CM.

It uses a Spohn Thrustator rotation joint, and there spherical delrin rod end.

It also uses a poly transmission mount.

Well I will let pictures tell the rest.

I gained 1.375" of ground clearance.

2) I always dragged my tunnel mount cross brace on speed bumps.

3) I wanted to reduce vibration under my seat for daily driving.

4) Most important was to strengthen the points where the tunnel mount cross member bolted to the car.

5) I did not want to remove my existing welded in subframe connectors.

I made this Torque Arm Cross Member up out of 4130CM.

It uses a Spohn Thrustator rotation joint, and there spherical delrin rod end.

It also uses a poly transmission mount.

Well I will let pictures tell the rest.

I gained 1.375" of ground clearance.

#4

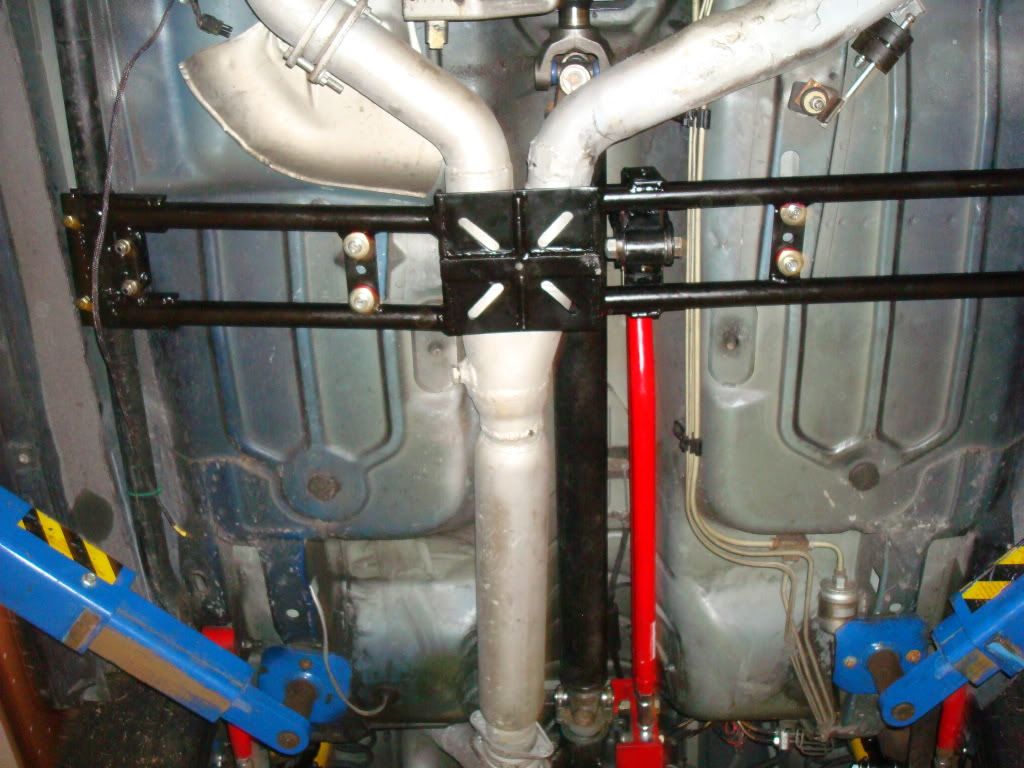

The bolts that go where the cross member bolt to the old tunnel brackets are the factory 8mm? but the end clamps are 3/8 grade 8. But they take no direct stress as the primary force is up and that is taken up by the 4130 pipe cut in half.

I still haven't lowered it down from the lift but the y-pipe doesn't move andwhen banged doesn't touch the brace. I am worried about the top of the Dog bone brace if hit multiple times will ring the drive shaft. Those transmission mounts allow flex in what if used in the original intended use would be back a forth. It will depend if the force of the rear end is straight up or not as to wether I will have issues.

I still haven't lowered it down from the lift but the y-pipe doesn't move andwhen banged doesn't touch the brace. I am worried about the top of the Dog bone brace if hit multiple times will ring the drive shaft. Those transmission mounts allow flex in what if used in the original intended use would be back a forth. It will depend if the force of the rear end is straight up or not as to wether I will have issues.

#5

Hope that solves all your probs, but even with the isolaters on the bottom of the fram rails, it would still seem that you are going to have the vibrations. Pretty good engineering too. At first it seems like once you got on it and the tq arm put any stress on it, it would try to come thru the floor board and rip it in half, but after looking at it closer you have those inner mounting points and rubber isolaters, so it should equally distribute the stress from the tq arm....Good job

#6

Hope that solves all your probs, but even with the isolaters on the bottom of the fram rails, it would still seem that you are going to have the vibrations. Pretty good engineering too. At first it seems like once you got on it and the tq arm put any stress on it, it would try to come thru the floor board and rip it in half, but after looking at it closer you have those inner mounting points and rubber isolaters, so it should equally distribute the stress from the tq arm....Good job

Trending Topics

#8

Just got back from the test drive. I couldn't be happier. I can't even tell I've got a rear end. No clunk on braking , no vibration in the seat what so ever. No exhaust rattle.

#11

Good idea. The only thing I would add is some gussets to these areas. I would be paranoid about the torque arms up and down force would snap the welds at the plate without them (maybe even with them).