Custom CNC Engraving

#1

I'm looking for a Houston area company to custom engrave a set of billet coil covers. I've called a few companies and was turned away because i'm an individual with a one-off and not a company dealing with volume. Any help or insight would be greatly appreciated.

Thanks for your time

Thanks for your time

#3

12 Second Club

iTrader: (44)

Join Date: Jan 2007

Location: Houston, Texas

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

what you need to do is find someone thats good with a program like mastercam. the hardest part is getting the program right. setting them up to run in a machine is easy. If you can find someone to draw out the engraving and save the the G-code to a flash drive for you then you might have better luck getting a shop to do it.

I work in a CNC shop and would be happy to help but all the machines are running 24/7 on something making it hard to do custom work.

I work in a CNC shop and would be happy to help but all the machines are running 24/7 on something making it hard to do custom work.

#5

I’m not entirely sure what all is needed.. I’ve got copies of the logo and was told they can send me some other kind of file if needed..?(not entirely sure what kind of file he was talking about but I didn’t recognize it)

thanks for the heads up.

EDIT: all im trying to get engraved is a shops name. just text. nothing special

thanks for the heads up.

EDIT: all im trying to get engraved is a shops name. just text. nothing special

Last edited by Corona-Extra; 02-23-2010 at 06:43 PM.

#6

TECH Resident

iTrader: (16)

Join Date: Feb 2007

Location: Baytown, Tx

Posts: 802

Likes: 0

Received 0 Likes

on

0 Posts

what you need to do is find someone thats good with a program like mastercam. the hardest part is getting the program right. setting them up to run in a machine is easy. If you can find someone to draw out the engraving and save the the G-code to a flash drive for you then you might have better luck getting a shop to do it.

I work in a CNC shop and would be happy to help but all the machines are running 24/7 on something making it hard to do custom work.

I work in a CNC shop and would be happy to help but all the machines are running 24/7 on something making it hard to do custom work.

#7

Teching In

iTrader: (1)

Join Date: Nov 2008

Location: North Korea

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

JG Fab/BMC Fab.

They are in Katy off of Mason, its been a while, but its worth the check. The old man can do anything you want.

They're in the industrial park behind the Discount tire.

They are in Katy off of Mason, its been a while, but its worth the check. The old man can do anything you want.

They're in the industrial park behind the Discount tire.

Trending Topics

#8

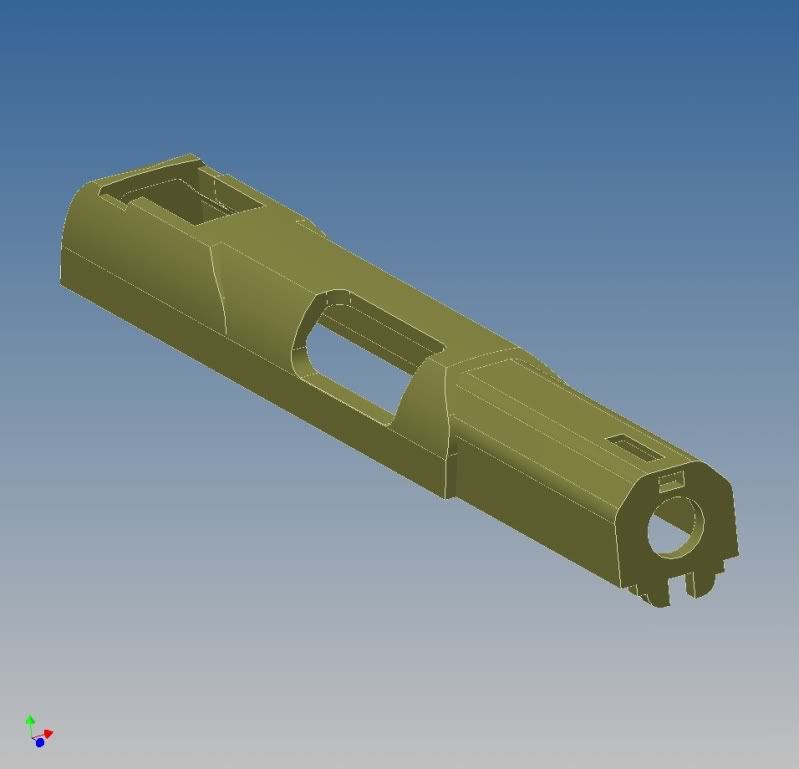

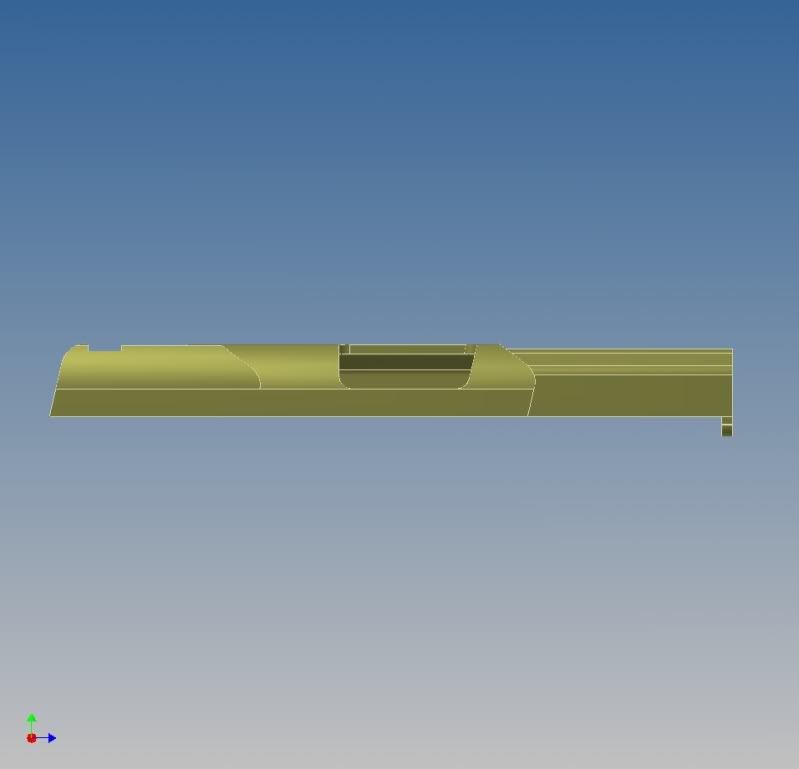

I am also in the same boat. I have designed a custom gun slide in Autodesk Inventor and i want to get it made. What is the process you go through to take that information from a 3d modeling program into a CNC? Is the process easier because because it was made in that type of program?

But yes, the process is easier if you have a .dwg. Some programs require you to draw the file in that program, some can import drawings.

#9

On The Tree

iTrader: (19)

Join Date: Mar 2006

Location: Hartselle,Alabama

Posts: 113

Likes: 0

Received 0 Likes

on

0 Posts

I live in Alabama and i can most likely help on the machining part if you don't mind shipping the parts. I have access to mastercam, solid works, and can do whatever needed to be machined

#11

On The Tree

iTrader: (19)

Join Date: Mar 2006

Location: Hartselle,Alabama

Posts: 113

Likes: 0

Received 0 Likes

on

0 Posts

That gun slide would be an expensive piece. Those normally come as castings and only have a few areas that are machined. I deal with parts like that all the time. What you are looking at would take a lot of time but could be done