DIY electric cut out

#2

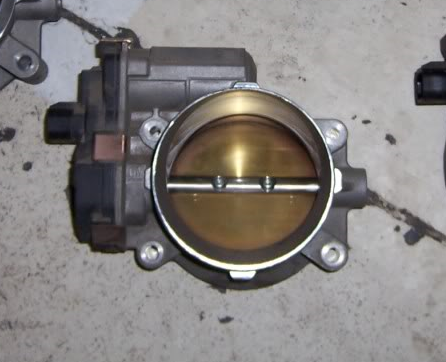

I just thought about something.... I wonder if the DBW Throttle body would work, lol... It can take the heat of the engine bay, I wonder if it would hold up as a E-Cutout?!

The collectors on my LT are 3.5" and the standard TB seems to be 90mm / 3.54"... Hmmm....

The collectors on my LT are 3.5" and the standard TB seems to be 90mm / 3.54"... Hmmm....

#7

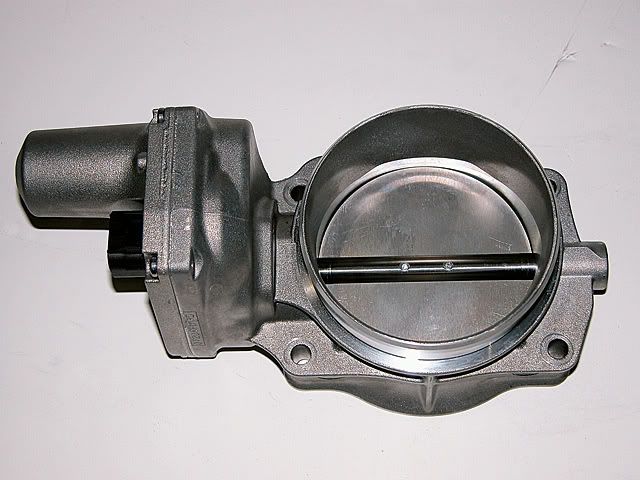

It would be pretty simple. Just need to make a "dump" with the same bolt pattern as the TB you want to use. Then find a OEM style connector that would typically plug into the TB to send a regulating voltage to it.

Would need to have a button or switch that supplies the needed voltage to the TB to open a specified amount.

I'm not 100% on what the operating range of the TB is, but if it is 0V-5V then you can have a potentiometer style **** in the cabin that can vary the angle of the TB based on the turning of the ****. Kind of like an amplifier adjustable "gain" ****.

Some have made a cutout using a mechanical/cable driven TB. Using a "choke" cable to open/close the TB.

Would need to have a button or switch that supplies the needed voltage to the TB to open a specified amount.

I'm not 100% on what the operating range of the TB is, but if it is 0V-5V then you can have a potentiometer style **** in the cabin that can vary the angle of the TB based on the turning of the ****. Kind of like an amplifier adjustable "gain" ****.

Some have made a cutout using a mechanical/cable driven TB. Using a "choke" cable to open/close the TB.

Trending Topics

#8

It would be pretty simple. Just need to make a "dump" with the same bolt pattern as the TB you want to use. Then find a OEM style connector that would typically plug into the TB to send a regulating voltage to it.

Would need to have a button or switch that supplies the needed voltage to the TB to open a specified amount.

I'm not 100% on what the operating range of the TB is, but if it is 0V-5V then you can have a potentiometer style **** in the cabin that can vary the angle of the TB based on the turning of the ****. Kind of like an amplifier adjustable "gain" ****.

Some have made a cutout using a mechanical/cable driven TB. Using a "choke" cable to open/close the TB.

Would need to have a button or switch that supplies the needed voltage to the TB to open a specified amount.

I'm not 100% on what the operating range of the TB is, but if it is 0V-5V then you can have a potentiometer style **** in the cabin that can vary the angle of the TB based on the turning of the ****. Kind of like an amplifier adjustable "gain" ****.

Some have made a cutout using a mechanical/cable driven TB. Using a "choke" cable to open/close the TB.

Oooo... I like that idea! That way you know if your cut out is half open or fully open, but the make on the ****. Not sure if there's a legit point to having it half or quarter open, but cool idea!

#9

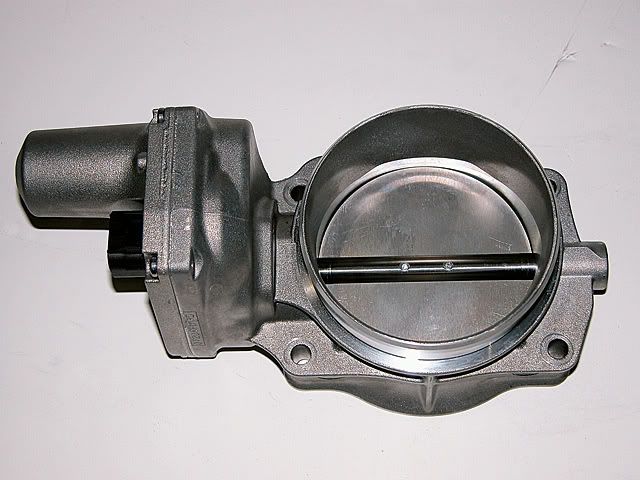

My biggest worry would be longevity. How it does with the heat and the elements. I know it gets hot under the hood, but sitting that close to the collector is a different story. As for the manual TB, I was looking at solenoid that could be mounted in a different spot, away from the heat of the collector.Something like a remote oil filter or water pump, etc.

#11

The speed shop that I trust said that ALL electric cutouts fail. Some last longer than others. Heat is your biggest issue. I believe it since it is simply an electric motor...and electric motors hat heat. If this is a weekend warrior...then it may last a while.

Either make a "remote mount" method, or make a good heat barrier.

Either make a "remote mount" method, or make a good heat barrier.

Last edited by smitty2919; 05-14-2014 at 08:23 AM.

#12

TECH Apprentice

iTrader: (1)

The speed shop that I trust said that ALL electric cutouts fail. Some last longer than others. Heat is your biggest issue. I believe it since it is simply an electric motor...and electric motors hat heat. If this is a weekend warrior...then it may last a while.

Either make a "remote mount" method, or make a good heat barrier.

Either make a "remote mount" method, or make a good heat barrier.

so this thread intrigues me too but mainly on maintenance aspect! Cheers everyone

so this thread intrigues me too but mainly on maintenance aspect! Cheers everyone

#13

Unless someone has found a replacement motor for these cutouts it will always be an issue. It would be nice to somehow spec out a power seat motor, or window motor etc.

I wouldn't imagine that these cutout motors are specifically designed/made for cutout applications. Someone needs to take one apart and see if you can find a P/N on it.

I wouldn't imagine that these cutout motors are specifically designed/made for cutout applications. Someone needs to take one apart and see if you can find a P/N on it.

#14

TECH Addict

Join Date: Jan 2002

Location: Magee MS

Posts: 2,950

Likes: 0

Received 0 Likes

on

0 Posts

good idea.... but I don't this its gunna hold up. Your looking at exhaust temps in the 400-1400* range. depending on the location of the cutout, but its HOT and I don't believe the internals of the throttle body are going to hold up well. Now I will admit that I COULD be wrong, but I don't think its gunna work for very long.

#17

Since heat kills, use a cable-driven throttle body and remote-mount the motor... just like the traction-control was set up for 4th gen f-bodies. That way you end up only needing to replace the cable. And space won't be as much of an issue.

#19

13 Second Truck Club

iTrader: (17)

Join Date: Aug 2008

Location: baton rouge

Posts: 637

Likes: 0

Received 0 Likes

on

0 Posts

I can say for a fact I made a cable driven tb cutout and it works and does not leak at all. The small hole has to be blocked off with bolt and nut. I started it when I messed up the iac and broke a couple of screws off and I was putting cutout that was going to have to be unbolted to open. So I made a flange and bolted it to my pipe and no leaks so I made cable that entered between my seat and console mainly so no one can see it and laugh when they find out its a throttle body!

#20

TECH Addict

I can say for a fact I made a cable driven tb cutout and it works and does not leak at all. The small hole has to be blocked off with bolt and nut. I started it when I messed up the iac and broke a couple of screws off and I was putting cutout that was going to have to be unbolted to open. So I made a flange and bolted it to my pipe and no leaks so I made cable that entered between my seat and console mainly so no one can see it and laugh when they find out its a throttle body!