Fuel Delivery Tech: Carb vs TBI vs MPFI vs DI

So, you’re ready to finish off that LS-engine you’re building with a way to send fuel into your combustion chamber. With the LS, you have a choice to make: Do you go old school with a carburetor? Do you retain the multiport fuel injection your engine originally came with?

Go with something in between with a throttle body injection? What about direct injection like on the LT1 and LT4? You have some interesting choices to make as each one has its advantage and disadvantage.

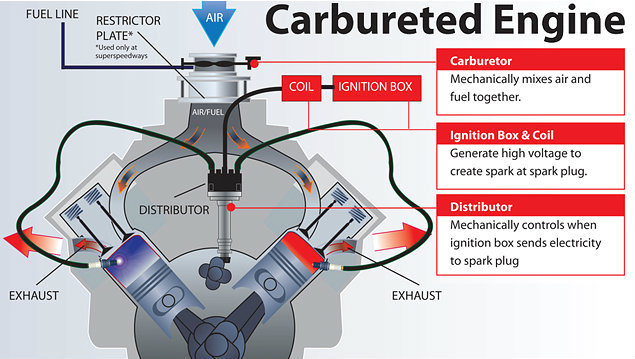

Carburetor

Let’s start off with carburetors, the old school way of getting fuel down into the cylinders. Carbs are pretty simple though explaining how they work is a bit complex. It comes down to air pressure between the venturi and the throttle. If you look at the carburetor from the bottom where the throttle plate is, you’ll see that the hole isn’t straight through. It necks down about halfway between the choke (if you have one) and the throttle plate.

This necking down and the shape of it causes the air to increase in velocity and create a high-pressure area in the neck and a low pressure area above and below it. You’ll also notice a second venturi, but we’ll get to that in a second. This pressure difference draws fuel out of the reservoir where your float is located and atomizes it before it gets sent down to your intake runner.

That second venturi is there to create an even greater pressure drop and causes more fuel to be pulled out of the reservoir. The float in that reservoir prevents too much fuel from being drawn in and refills it when it gets to a certain level.

You’ll hear those old-school guys talk about rejetting a carburetor, essentially they are changing the size of the hole that sprays that fuel that the venturi is pulling in. They can also adjusting the needle and seat valves to adjust the amount of fuel dumping into the primary or secondary float assembly on a Holley.

There are also off-idle circuits that feed fuel when you’re off the gas pedal, a power valve that opens with engine demand via its vacuum (unless you have a Carter, a Rochester Quadrajet, or one based on either of those designs which used a metering rod or several of them), and an accelerator pump to compensate for the throttle opening faster than fuel demand; all of these can also be adjusted per application or even per situation.

As you can see, there are many ways that a carburetor can fuel your engine just depending on which one you happen to buy and use. It seems very complicated and almost like black magic but really it’s pretty simple once you sit down with it and see how it all works.

However, this is an old school technology that hasn’t been used on a modern car since the 1980s. Why do so many engine builders still use it? Well, other than it’s what they know, a carburetor can make some big power and it’s because of how it’s sending your fuel to your cylinder. When you inject fuel into the intake manifold, it cools the intake runners and makes denser air. Denser, cooler air makes more power and that’s a positive.

If that is true, how come more performance cars don’t have them? Well, a carburetor makes efficient power within a certain RPM window depending on where you tune if for, atmospheric conditions, and even as fuel sloshes around in your float chamber (though that isn’t so much an issue anymore). It’s why drag racers love the carburetor, though many are starting to take in fuel injection.

In NHRA Pro Stock for this year, they have to and many grumpy fans that have never touched a drag car in their life and think they are professional Facebook carb tuners because of YouTube couldn’t be more upset.

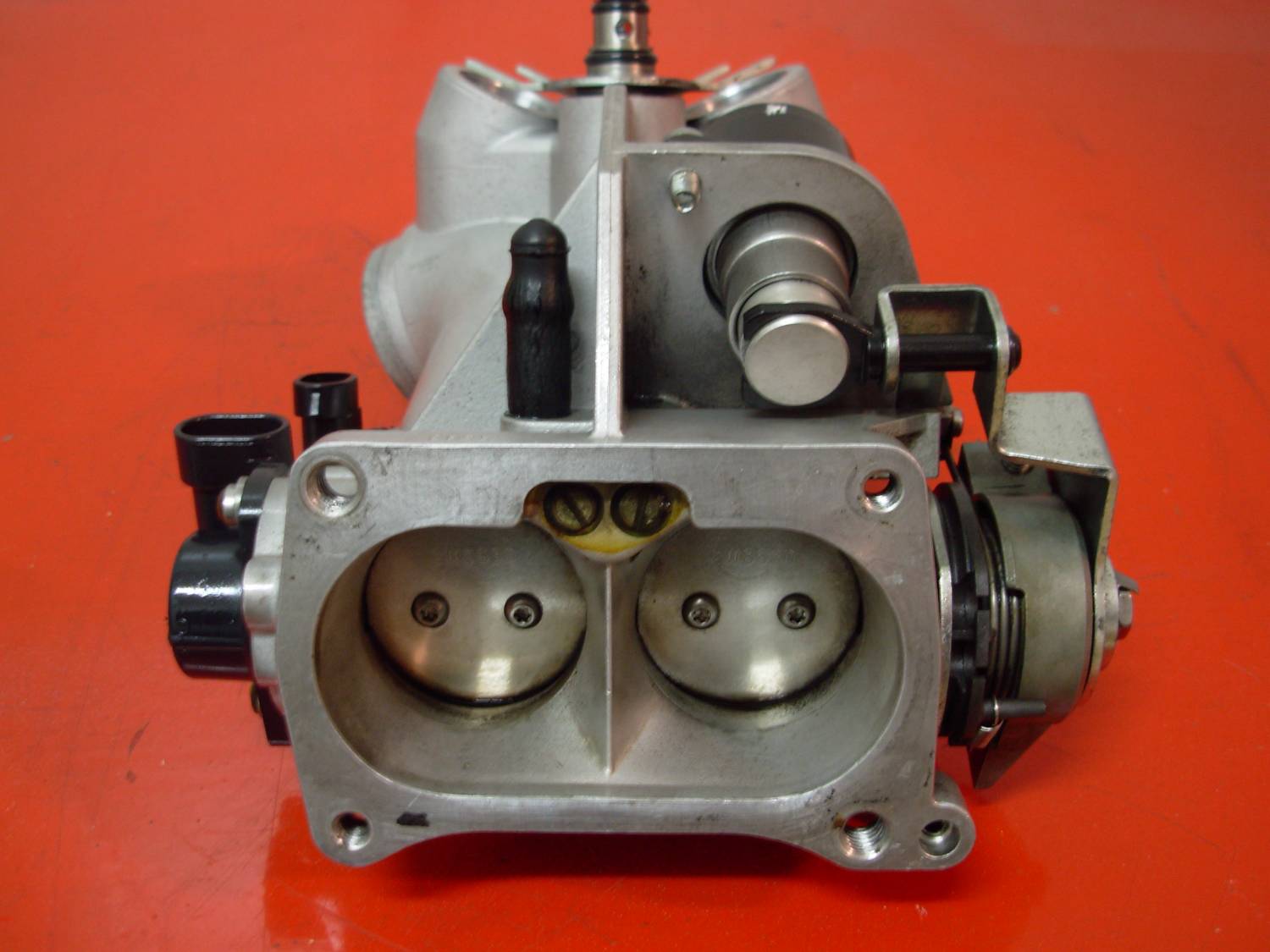

Throttle Body Injection

We’re going to skip mechanical injection, as that’s an article just by itself, and go into the first real step into modern fuel injection with the Throttle Body Injection (TBI) system. You’ll look at it and say “oh, it looks like a two-barrel carburetor,” and that’s where the similarity mostly stops.

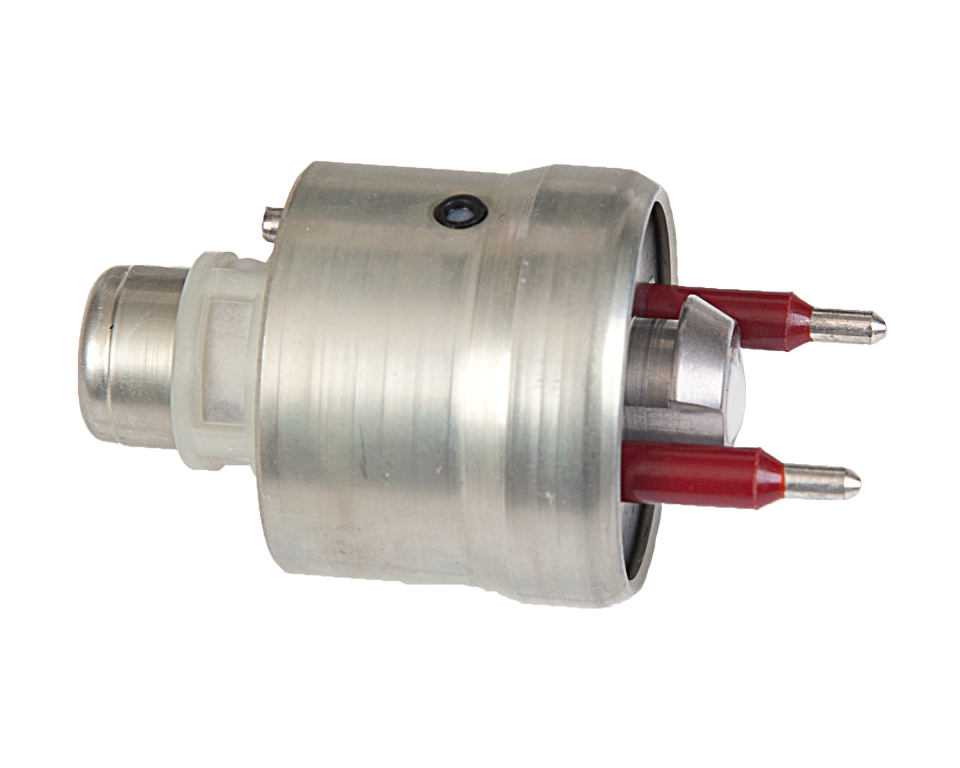

There are no venturis, power valves, jets, or any of those parts like in a carburetor. In most cases, the throttle body injector has two large fuel injectors sitting on top of a throttle plate. It’s a low pressure system kind of like a carburetor but the pressure is also, again in most cases, higher than in a carb system. Fuel is injected based on a fuel table that the engine control unit (ECU) sees that the engine needs based on air flow, engine demand, and the amount of oxygen left after the fuel is burned.

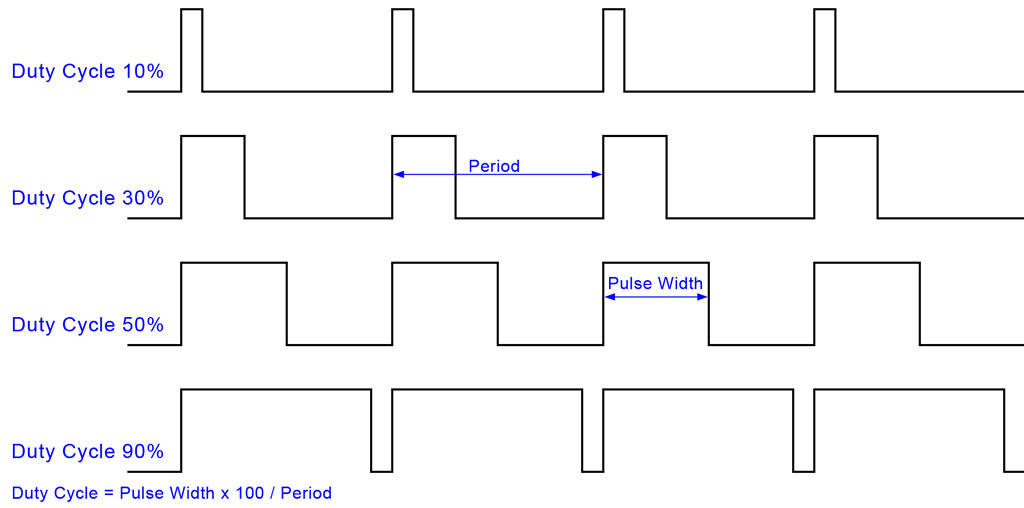

Inside of the injector are several needles and seats that allow atomized fuel to flow past and into the intake manifold. These needles are opened and closed thousands of times per second per RPM. How much and how long they are open are determined by the ECU and is done with pulse width modulation (PWM).

What that means is that it’s like working a light switch on and off: the pulse is a square wave of a 1 (on) or 0 (off). When the ECU sends that on signal the needle opens, when it sends the off signal, the needle closes and it does this several times a second to the point that you can’t see it even with a strobe light.

It has a similar advantage as a carburetor in that it helps make the intake runner temperature lower and the air denser since its injecting fuel above the runner. Carburetor graduates like it for that reason and it is a little simpler to use when compared to Multiport Fuel Injection.

It is more precisely controlled but is still RPM window limited in where it can make power, it’s just the window does get a little bigger over a carburetor. The disadvantage is that you have to tune with a laptop or some sort of dongle that controls the ECU. This means graphs and tables and lots of numbers to the uninitiated. It’s also not as precise or efficient at Multiport Fuel Injection and is, again, why we don’t see it any more.

We haven’t seen TBI since about the 2000s with the 4.3-liter Vortec V6 and the last V8 was in the Generation II, the original LT-based engines not the new LT that we see now. Man that gets confusing and old quick.

Multiport Fuel Injection

The next most current fueling method is the Multiport Fuel Injection (MPFI). It’s also known as Tuned Port Fuel Injection, Intake Runner Injection, and several specialized names from different manufacturers to mean the same damn thing. It’s what your LS or LS-based engine came with and has been in use since the mid to late 1980s on domestic cars and even earlier on imports.

This is nothing like either carburetors or TBI as the intake design and injector design are different. However, the injector is fairly similar to how a TBI works with PWM control and needles, just on a much smaller scale and much higher fuel rail pressures. The pressure is higher to atomize the fuel more. The timing of that PWM and the tables you use are also far more precise and can be tuned for throttle position, manifold pressure, RPM, lambda (oxygen reading), boost, and a wide variety of other factors.

That fact alone turns old school carburetor guys off of MPFI off the bat. It seems complicated because there are so many numbers and tables to tune on and you have to use a computer and damnit a smartphone is already hard to work with how am I going to use that?!

There is also the issue of intake runner temperature; because the fuel is being atomized right at the intake valve inside the runner, the air temperature is higher and less dense. However, that can be overcome because the cylinder temperature can be lowered because the atomization is now happening just at the intake valve.

That is a pretty big advantage to throw away because you’re scared of a computer. You can also simplify tuning on MPFI (and TBI to a certain degree) as you can have the ECU monitor and automatically adjust for changes in engine demand, atmospheric pressure, air temperature in the intake, ambient air temp, lambda reading, or nearly anything.

The hard headed of the old school will say “why not just let the computer drive the damn car?!” Well, honestly, you’re still adjusting the air/fuel mixture. You’re still doing the same thing as you would a carburetor, just at a finer and more precise scale. Hell, you can still look at your spark plug and tell which cylinder needs fuel and be able to tune for it without really upsetting the rest of the engine.

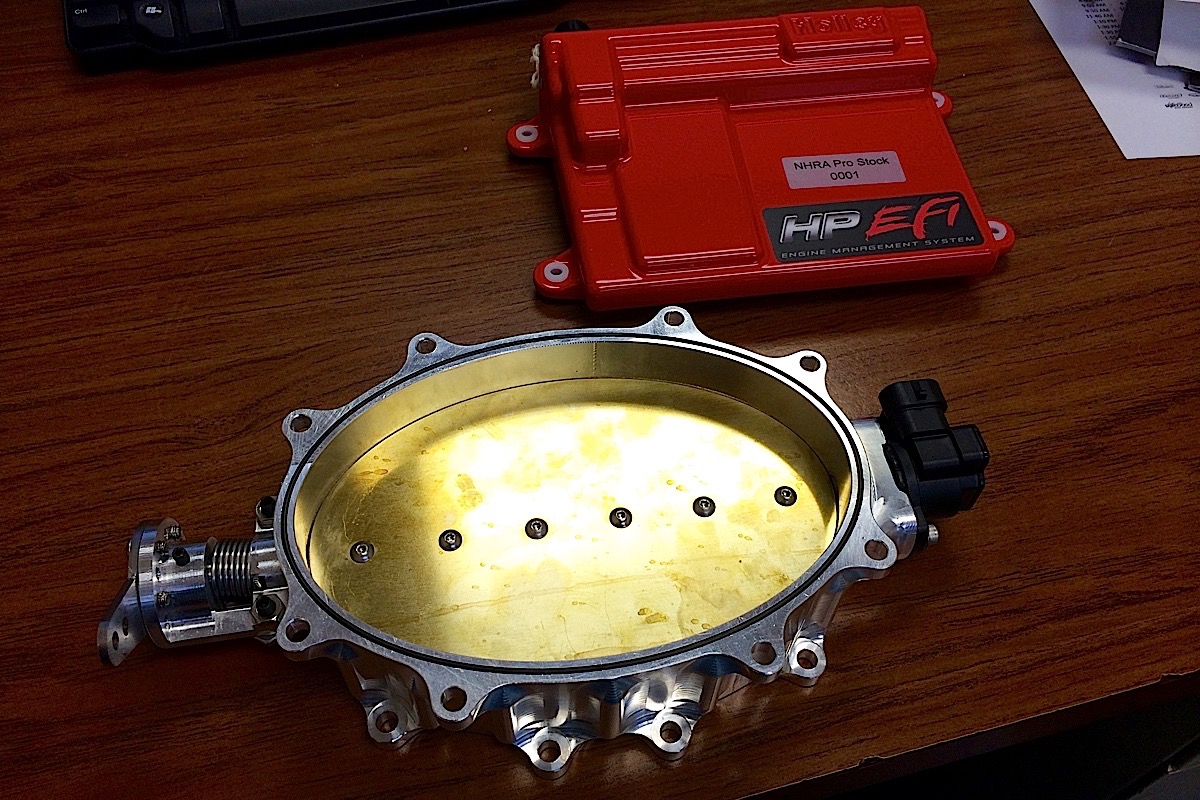

Now, I mentioned the issue with Pro Stock and that they are switching to MPFI engines this year (2016 in case you’re reading this at a far later date).

From tests that have been done so far, these guys are not far off their numbers with carburetors and with work into the season we’ll see them going faster before the final rounds. One issue that has come up is feeding the each cylinder with the same amount of air.

This issue is due to the design of the intake manifold that they have to work with and not because of MPFI. If they were able to use individual throttle bodies (ITB) instead of the single body at the front with log manifold that feeds the runners, this wouldn’t be an issue.

However, expect that to become a non-issue by next year or sooner as they develop these cars or the NHRA opens up to ITBs. Not likely, but one can dream.

Direct Injection

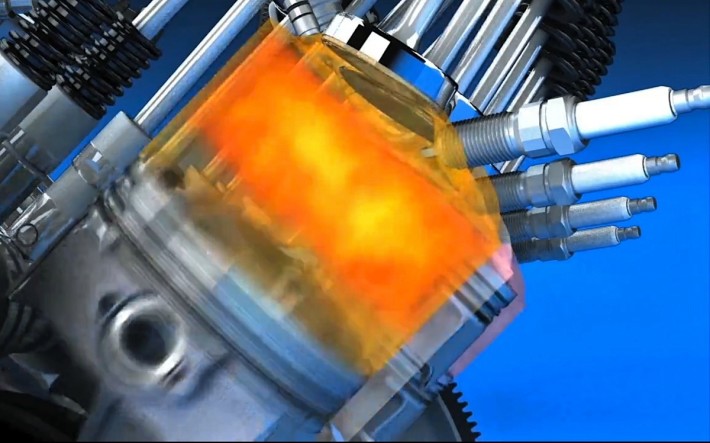

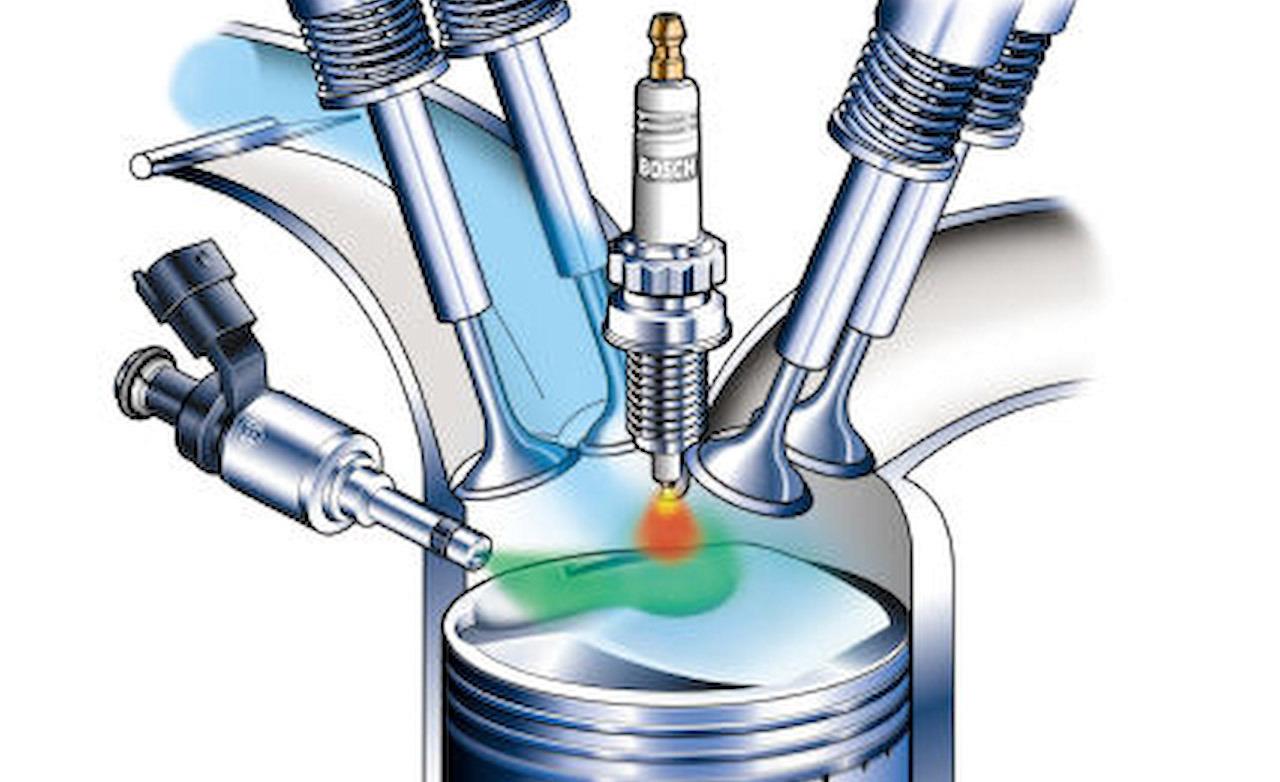

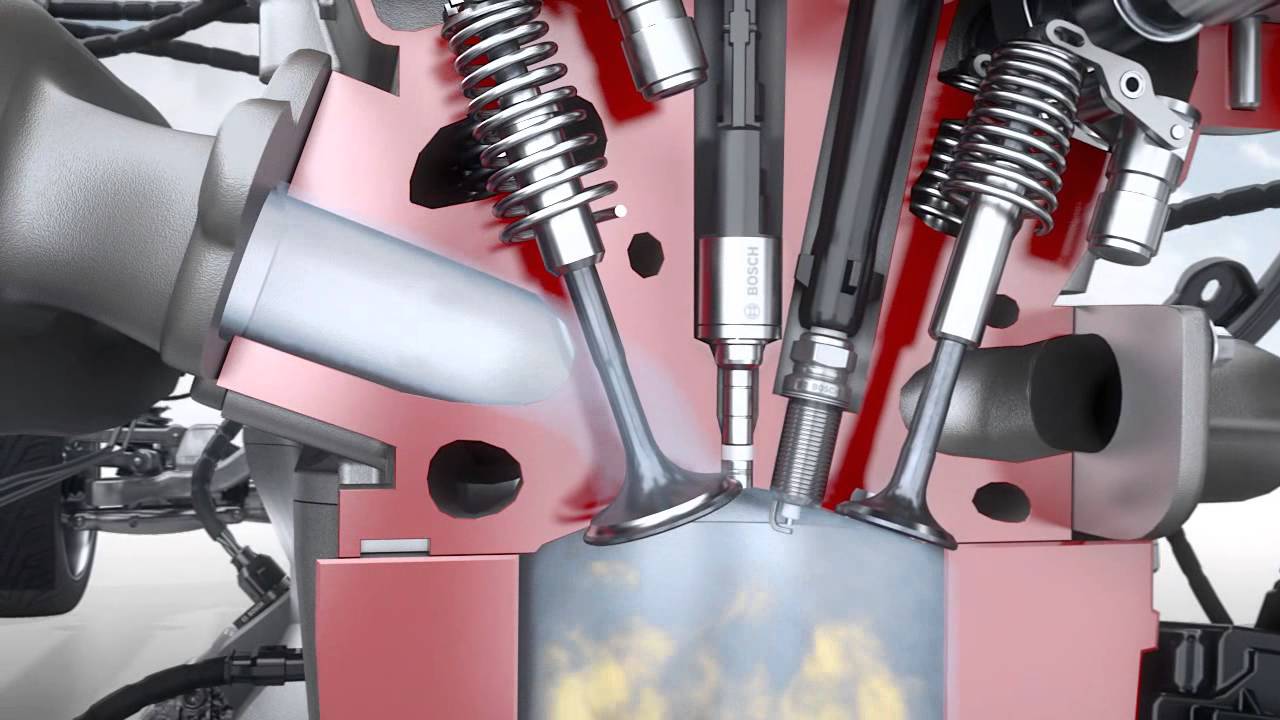

This fuel injection technology is the latest and currently the greatest, well for gasoline. Direct Injection (DI) has been around for diesel injection for quite a while longer. The way this works is exactly like MPFI, but instead of an injector right at the intake valve it’s in the combustion chamber.

There are two trains of thought on how this should be done. The first is a side feed known as a “wall guided” DI, looks like the same place where a spark plug would be on the LS head. It feeds fuel into the piston with a cupped dish that causes the fuel to swirl for a better fuel pattern and flow upwards into the ignition area.

The second is known as “spray guided” DI and it puts the injector between the valves much like the spark plug on a pent-roof or hemi-roof combustion chamber. It doesn’t necessarily need a specialized piston like a wall guided DI, but manufacturers will design pistons to take advantage of the design as well.

Other than a pretty complicated injector design sometimes using a piezoelectric (an electric charge accumulated in crystal, ceramic, or biological matter very, very quickly) circuit inside the injector and very, very high fuel pressures (anywhere up to 26-thousand-PSI), the disadvantage is similar to MPFI with higher intake runner temperatures and the complexity with tuning with a computer.

However, the advantage is like the MPFI but several fold. Because you can inject the fuel right at the source, at the most precise time, with the most precise amount and several times if you have to; you can get the most efficiency out of gasoline, the best fuel mileage, and usually more power.

You also get even lower combustion chamber temperatures allowing you to run very high compression ratios with minimal predetonation on lower octane fuels. It’s why the new EcoTec3 engines can run on either regular or premium fuels with minimal power loss and no ping on either fuel. Though, you’ll get more power with premium fuel just because of its predetonation properties.

While we are still learning in the aftermarket on what we can get away with on DI cars, we’re going to see some really incredible gains when we do. Just like with MPFI or even TBI when both of those came out, it will cost a little more but in the end we’ll see the prices drop and the power increase. Maybe even faster than we ever dreamed possible on those.

Fuel injection, carburetors, direct injection; they all seem very scary and magical at first blush. However, it doesn’t matter what you’re using as in the end the goal is the same. Make the most power, with the right amount of air/fuel mixture, for what you’re trying to do with it and where. Hopefully, you’ll see that these aren’t scary technologies and just require time and experience with advantages and disadvantages in each case.