My 240sx / S14 LS1 Swap - Progress *56k beware*

#41

TECH Enthusiast

iTrader: (4)

Join Date: Nov 2001

Location: Atlanta, GA

Posts: 527

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by mmdb

Question about headers. If the JBA shorties were designed to fit with stock like fitament could these be used? They're PACESETTER PERFORMANCE EXHAUST HEADERS.

The company claims them to be carb legal so I'm assuming they fit just like stock with minor variations.

The company claims them to be carb legal so I'm assuming they fit just like stock with minor variations.

#42

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 184

Likes: 0

Received 0 Likes

on

0 Posts

^ Thanks for the info Ted! I'll keep looking around for set to see what will be the easiest way to get the headers to fit.

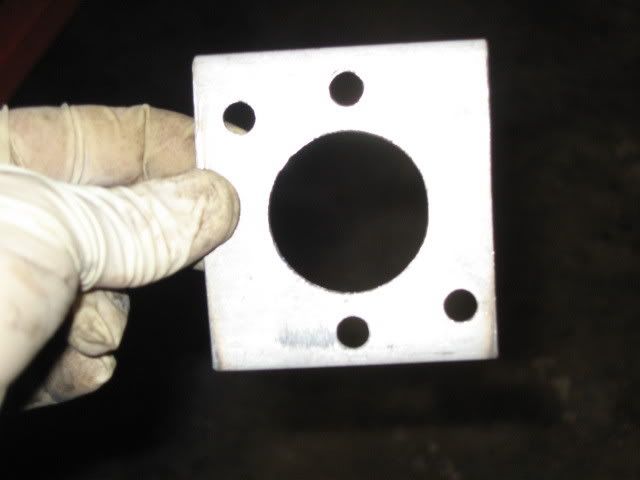

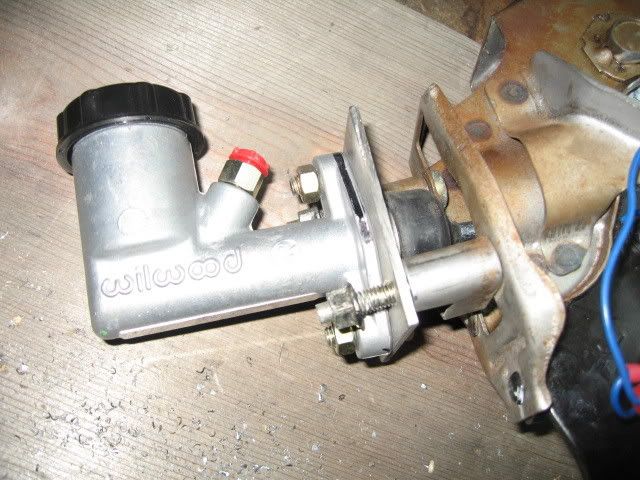

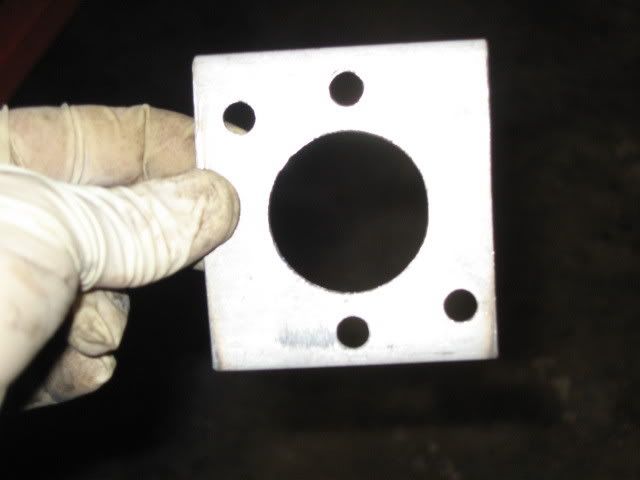

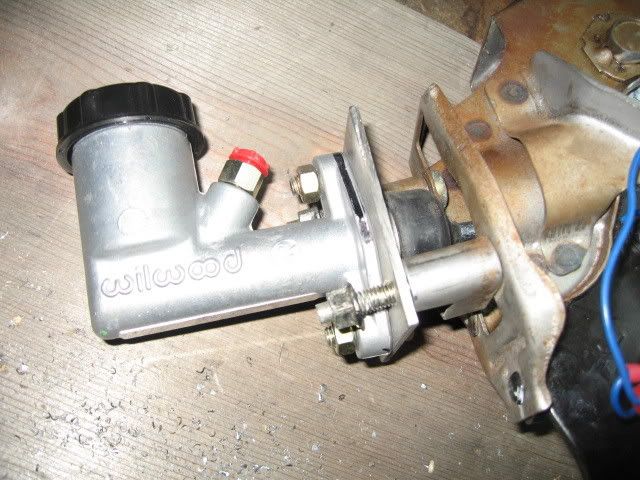

Some more progress! I've made a clutch plate to fit the Wilwood clutch master cylinder (CMC). I've used ls1neezy's idea (Here) and modified it a bit. Instead of threading the CMC I decided to create a plate that goes inbetween the CMC and the firewall/clutch pedal. In addition to the new design you have to drill 2 additional holes into the firewall to fasten the CMC fit to it. Reason I did this is because the firewall is so thin, having a plate in between the CMC and itself would provide better stiffness and a more sold feel. It also felt safer to me to use a bolt and nut to fasten the CMC in place than rethreading the holes on the CMC. I could think of other things why, but in essence it's easier and safer (IMHO).

Template for bolt patterns...

Pilot holes drilled....

I used a hole saw to make the 1 and 1/2" hole for the CMC. The other holes for the clutch pedal and CMC are 5/16".

And finally how it'll fit...

Some more progress! I've made a clutch plate to fit the Wilwood clutch master cylinder (CMC). I've used ls1neezy's idea (Here) and modified it a bit. Instead of threading the CMC I decided to create a plate that goes inbetween the CMC and the firewall/clutch pedal. In addition to the new design you have to drill 2 additional holes into the firewall to fasten the CMC fit to it. Reason I did this is because the firewall is so thin, having a plate in between the CMC and itself would provide better stiffness and a more sold feel. It also felt safer to me to use a bolt and nut to fasten the CMC in place than rethreading the holes on the CMC. I could think of other things why, but in essence it's easier and safer (IMHO).

Template for bolt patterns...

Pilot holes drilled....

I used a hole saw to make the 1 and 1/2" hole for the CMC. The other holes for the clutch pedal and CMC are 5/16".

And finally how it'll fit...

#43

TECH Apprentice

Join Date: Aug 2006

Location: Mobile AL.

Posts: 301

Likes: 0

Received 0 Likes

on

0 Posts

looks good. the plate seems like its the way to go. i know it looks easier then what i did.

i like that CMC you got better then mine too. mine looks much longer.

i like that CMC you got better then mine too. mine looks much longer.

#45

TECH Enthusiast

iTrader: (4)

Join Date: Nov 2001

Location: Atlanta, GA

Posts: 527

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by mmdb

^ Thanks for the info Ted! I'll keep looking around for set to see what will be the easiest way to get the headers to fit.

Some more progress! I've made a clutch plate to fit the Wilwood clutch master cylinder (CMC). I've used ls1neezy's idea (Here) and modified it a bit. Instead of threading the CMC I decided to create a plate that goes inbetween the CMC and the firewall/clutch pedal. In addition to the new design you have to drill 2 additional holes into the firewall to fasten the CMC fit to it. Reason I did this is because the firewall is so thin, having a plate in between the CMC and itself would provide better stiffness and a more sold feel.

Some more progress! I've made a clutch plate to fit the Wilwood clutch master cylinder (CMC). I've used ls1neezy's idea (Here) and modified it a bit. Instead of threading the CMC I decided to create a plate that goes inbetween the CMC and the firewall/clutch pedal. In addition to the new design you have to drill 2 additional holes into the firewall to fasten the CMC fit to it. Reason I did this is because the firewall is so thin, having a plate in between the CMC and itself would provide better stiffness and a more sold feel.

Or

Does it go CMC, firewall, plate, and then clutch petal?

I'm thinking it's the first one, just double checking.

#47

11 Second Club

iTrader: (23)

Join Date: Feb 2006

Location: Bowling Green, KY

Posts: 153

Likes: 0

Received 0 Likes

on

0 Posts

Didn't ls1neezy put the plate on the other side of the CMC (in effect sandwiching the CMC's mounting flange between the plate and the firewall)? Will putting the plate in between change the length of the stroke and initial pedal position? and if so, will it be enough to affect anything? I was planning on using aluminum and therefore making it thicker so it's strong enough. This question is the only reason I haven't done it yet. Am I making any sense or am I just hungover?

#49

Originally Posted by cnichols

Didn't ls1neezy put the plate on the other side of the CMC (in effect sandwiching the CMC's mounting flange between the plate and the firewall)? Will putting the plate in between change the length of the stroke and initial pedal position? and if so, will it be enough to affect anything? I was planning on using aluminum and therefore making it thicker so it's strong enough. This question is the only reason I haven't done it yet. Am I making any sense or am I just hungover?

yea mine goes plate , cmc, firewall . mine dose not flex at all b/c its bolted to the stock pedal assembly like the stock cmc would . rock solid . removal and intsall of mine is a 3min ordeal . easy . Dont forget to put the 240sx push rod in place of the pushrod that came with the wilwood .

#51

TECH Regular

iTrader: (1)

Join Date: Jun 2006

Location: Beaumont TX

Posts: 426

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by cnichols

Didn't ls1neezy put the plate on the other side of the CMC (in effect sandwiching the CMC's mounting flange between the plate and the firewall)? Will putting the plate in between change the length of the stroke and initial pedal position? and if so, will it be enough to affect anything? I was planning on using aluminum and therefore making it thicker so it's strong enough. This question is the only reason I haven't done it yet. Am I making any sense or am I just hungover?

#52

11 Second Club

iTrader: (23)

Join Date: Feb 2006

Location: Bowling Green, KY

Posts: 153

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by kansaschity

hey cnichols i just noticed your from stl. are you gonna make it out to the drift practice on march 17th at gir?

#53

Teching In

iTrader: (1)

Join Date: Oct 2006

Location: kansas city

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

cool, i'm going as long as everything goes as planned and my swap gets done within the next month. cool to see someone else in missouri with one in the works, afterall ford and gmc both have plants here in kc so theres always plenty of hicks with parts

#54

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 184

Likes: 0

Received 0 Likes

on

0 Posts

A little more progress. I got my x-member welded by Steen Fabrication in Long Beach, CA. When I picked it up I was VERY impressed by the welds. He (Gary the owner) seam welded other places to make it even stronger. To say the least I'm going to go to him from now on to do the welding. The x-member is reinforced with a 1/4" steel plate. I made it a priority to make this as strong as possible and to be safe as possible. From a previous pix ls1neezy provided you can see how much had to be cut. Here's the pix...

Last edited by mmdb; 02-07-2007 at 01:01 AM.

#56

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 184

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ls1neezy

sweeeeet . looks good ..

My next step is to approach the header problem. I'm thinking about getting a pair of JBA headers and chopping those but I have yet to decide. Motor mounts are next to be fabbed up.

Also, as for motor mounts, is the bottom of the x-member level with the bottom of the oil pan? I want to get a guesstimate of how I high I need my motor mounts to be made. I plan to get a set fabbed up before dropping in the motor. Although it's tricky, I think if I can get a general idea where everything lines up it'll then be a matter of massaging the firewall/transmission tunnel enough to get everything to fit.

#57

TECH Enthusiast

iTrader: (4)

Join Date: Nov 2001

Location: Atlanta, GA

Posts: 527

Likes: 0

Received 0 Likes

on

0 Posts

Wow, those are some sweet looking welds. Gotta love it when they not only make the weld look like it holds good but making it look good at the same time is neat. Man I wish I had a TIG welder!