LQ4 into a 3rd Gen/1972 Nova

#181

I decided a while ago to go with spherical rod ends as tie-rod ends to gain some much-valuable clearance in that area, and upon looking around and seeing the Baer Trackers kit for $169 (for so little, yikes!!) I figured I'd just make my own kit, especially since I already had nice new hex-bar tire rod sleeves.

I've been waiting on the special tapered pins for the steering arms, and that came in today. For a $14 part(s), it cost me $23 in "import fees" because of the size of the F***ING box...

...that REALLY pissed me off, that should've cost me nothing to get across the border. Last time I order from Speedway Racing.

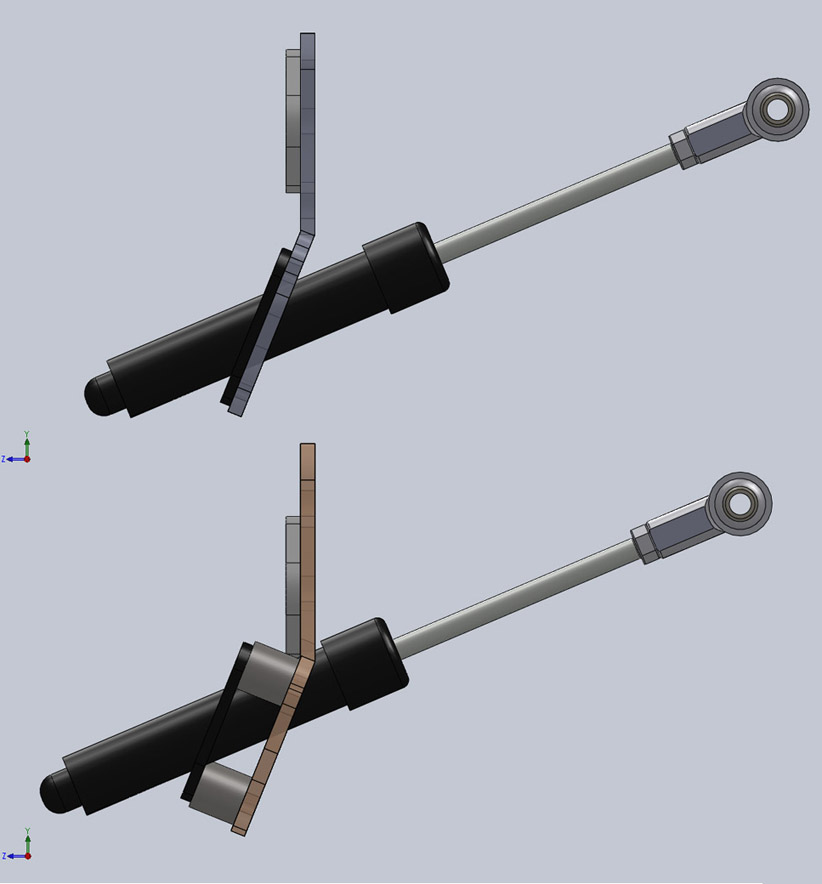

This is the mocked up assembly. I'm going to have B7 grade 5/8"-18 threaded rod connecting the female rod end & the sleeve, as well as drilling the tapered pin to accept castle nuts, and I will also turn down some nice spacers out of that chunk of SS rod to the left...

General idea of how it goes together...

This is a slightly deceiving picture, there's about 1/4" clearance between the rim & rod end and the closest location, but I'm still gonna space the steering arm 0.25"-0.5" depending on how I feel...

EDIT: don't know why I ever seconded-guessed possible clearance issues, there's plenty of room...

I've been waiting on the special tapered pins for the steering arms, and that came in today. For a $14 part(s), it cost me $23 in "import fees" because of the size of the F***ING box...

...that REALLY pissed me off, that should've cost me nothing to get across the border. Last time I order from Speedway Racing.

This is the mocked up assembly. I'm going to have B7 grade 5/8"-18 threaded rod connecting the female rod end & the sleeve, as well as drilling the tapered pin to accept castle nuts, and I will also turn down some nice spacers out of that chunk of SS rod to the left...

General idea of how it goes together...

This is a slightly deceiving picture, there's about 1/4" clearance between the rim & rod end and the closest location, but I'm still gonna space the steering arm 0.25"-0.5" depending on how I feel...

EDIT: don't know why I ever seconded-guessed possible clearance issues, there's plenty of room...

Last edited by frojoe; 08-02-2009 at 10:46 PM.

#182

11 Second Club

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

I would strongly recommend that you DON"T go that route. Safety issue. Stick with ball joints. Besides that, the heim joints wear out very quickly. About Speedway....told you so! (My $50 hose that cost $100)

#183

I don't think it would be terribly unsafe, but for a street application I can see what you mean with regards to slop/abuse/general reliability when there's other people out there near me.

I've brought the rim inboard about 0.75" and I thought for sure the inner lip would hit the tierod hence why I thought of going this route, but now I'm not as skeptical. I'll mock up the stock tierod, and if it's gonna work with just a little steering arm shimming I'll go with that for now, unless if I measure unreasonable bumpsteer in that setup.

I've brought the rim inboard about 0.75" and I thought for sure the inner lip would hit the tierod hence why I thought of going this route, but now I'm not as skeptical. I'll mock up the stock tierod, and if it's gonna work with just a little steering arm shimming I'll go with that for now, unless if I measure unreasonable bumpsteer in that setup.

#184

11 Second Club

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

Initially safety isn't the issue. The thing is is that those joints have no way to hold lubricant. I have seen them used on a certain pt cruiser, and they wore out very very rapidly, (less than 1,000 miles)

#186

TECH Fanatic

iTrader: (23)

And to my knowledge the truck and car O rings on the pickup are different. I dont know what your pressure issue was but Ive been told with a car o ring in a truck pickup you will have ok prsssure at idle but it drops when you raise the rpm.

#187

So I was really sick last week and didn't do much, and now that I'm better the weather is gross outside, so I messed around on the computer to figure out the clutch master bracket.

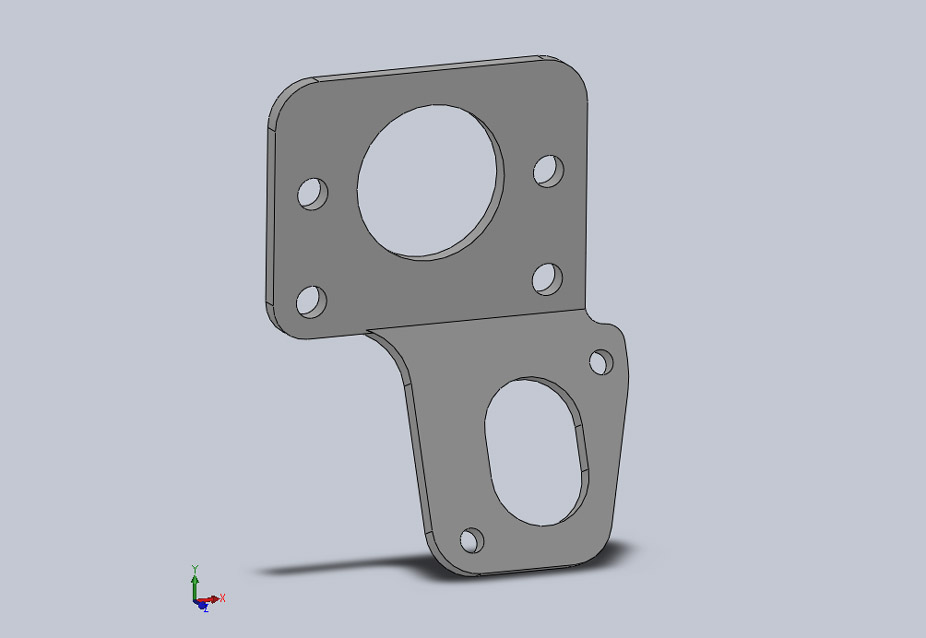

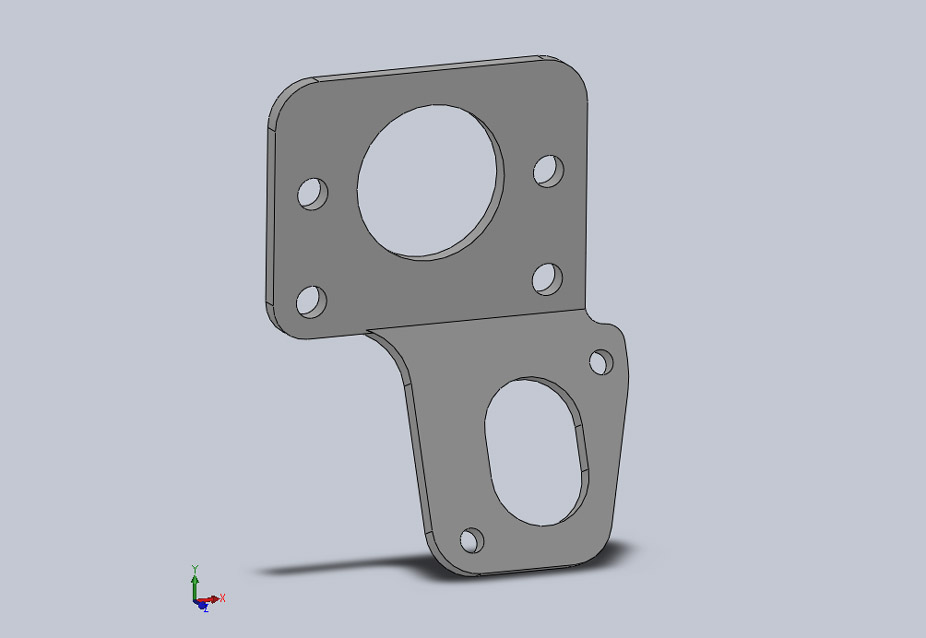

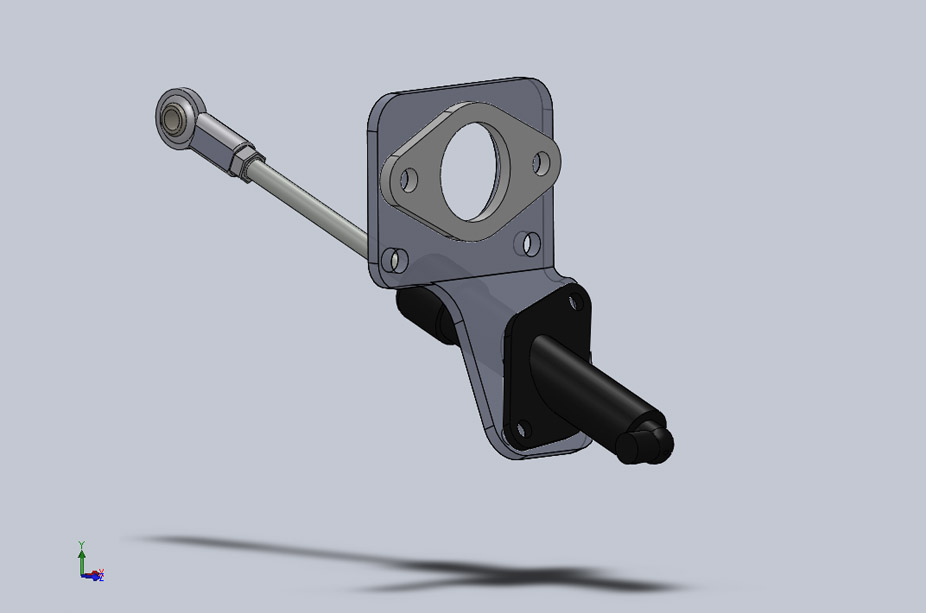

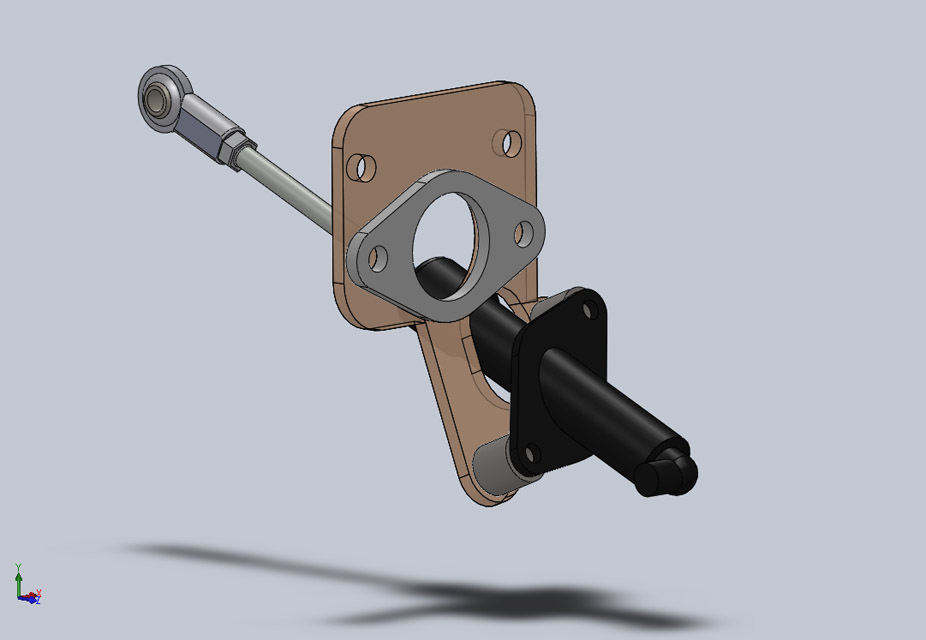

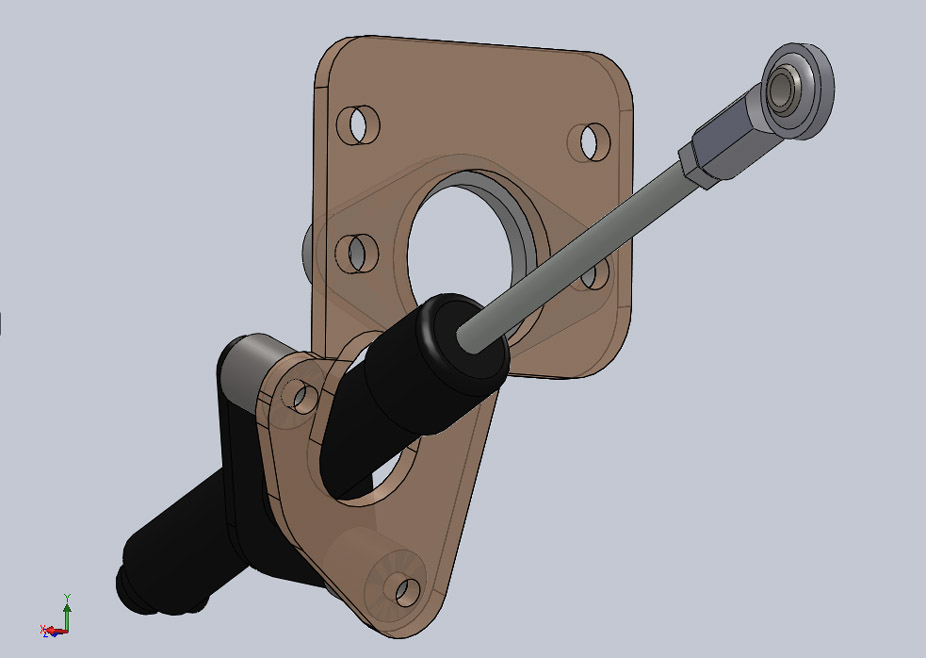

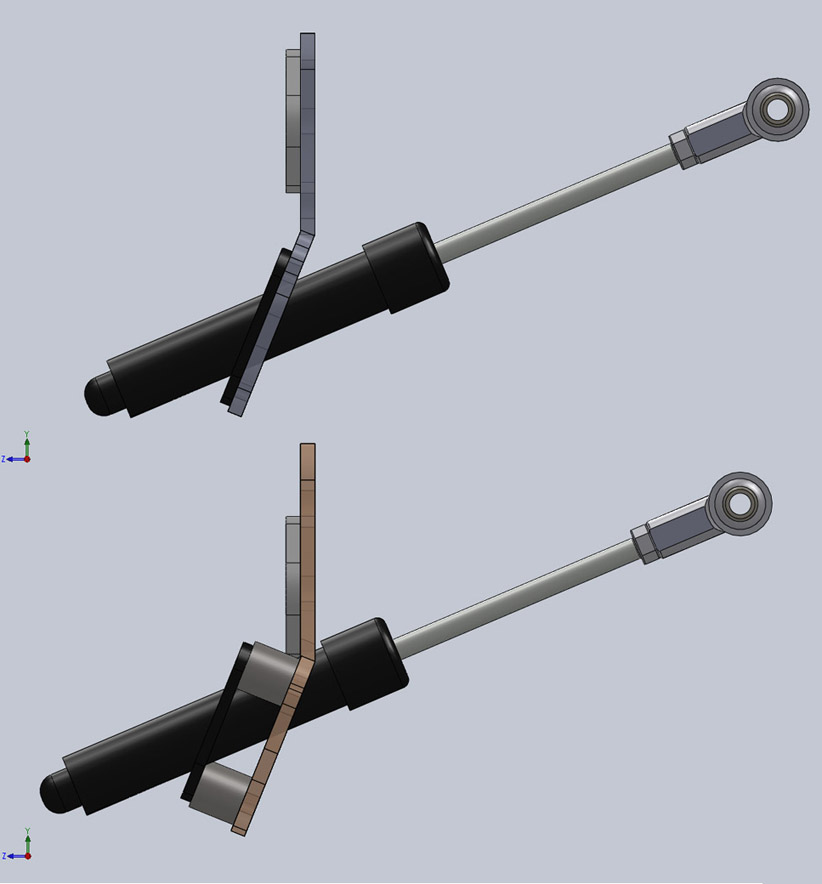

This is the DSE plate...

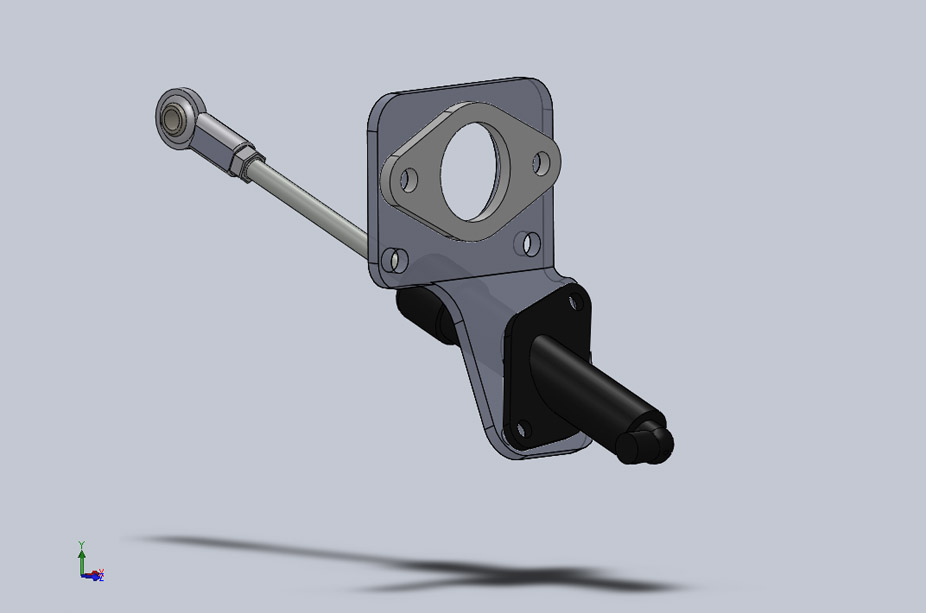

But it mounts the MC to the top pair of the four bolt holes...

...but I want to mount the MC to the bottom pair of the 4 bolt holes. This meant the bend in the plate would have to be moved down, to make some room for the MC's flange...

In order to keep the clutch master's rod axially the same as the DSE plate, the clutch master needs to be spaced out..

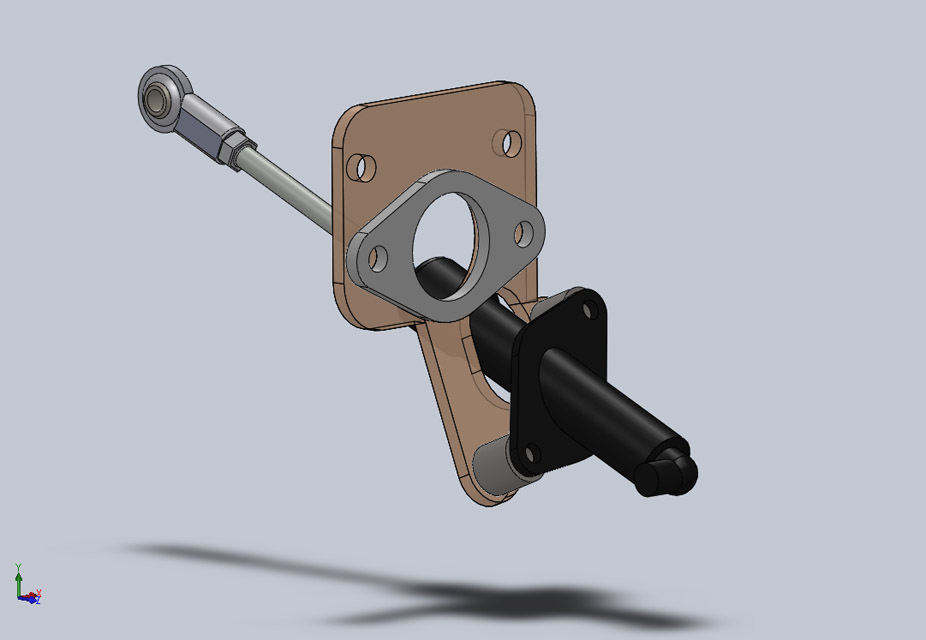

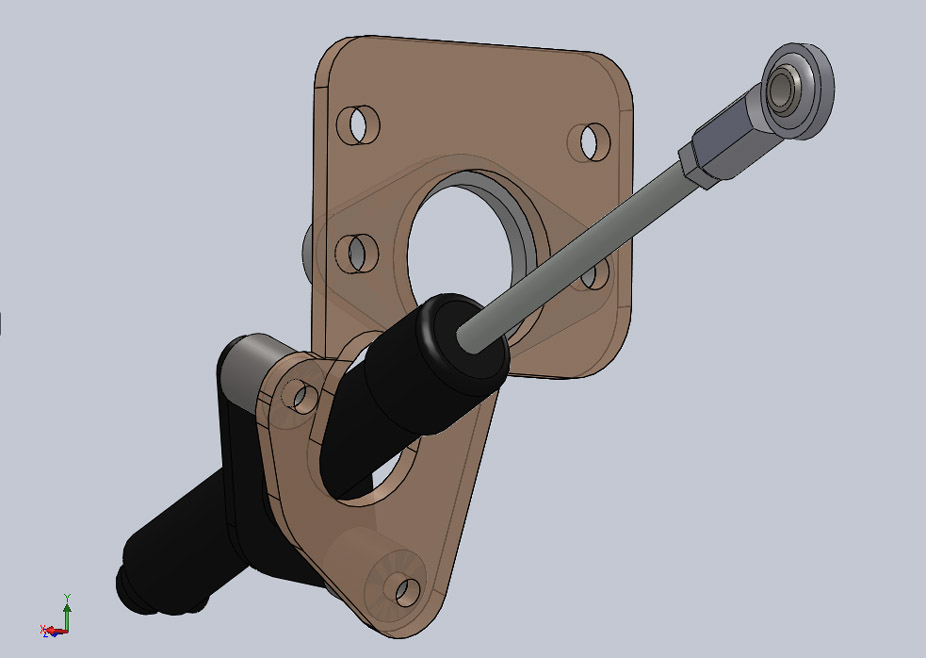

Comparo of DSE bracket (grey) vs. my bracket (brown)...

This is the DSE plate...

But it mounts the MC to the top pair of the four bolt holes...

...but I want to mount the MC to the bottom pair of the 4 bolt holes. This meant the bend in the plate would have to be moved down, to make some room for the MC's flange...

In order to keep the clutch master's rod axially the same as the DSE plate, the clutch master needs to be spaced out..

Comparo of DSE bracket (grey) vs. my bracket (brown)...

#188

So after leaving this thread dormant for a long-*** time, here's a small update.

I put on some JBA tubular headers just to roughly see the fitment. Not sure if I'm gonna use these or not, they have lots of ugly emissions junk on them I'd have to smooth off, not to mention re-weld a V-band flange, as well as them going quite up and out from the block. Hot side tubing might be pretty tight on the pass. side since the turbo would be a "top mount" and the pass. side tube would have to bend down and then back up to merge into the turbine inlet, all right where the coolant lines and lower radiator are

PS... thanks MARK for the usage of your headers for "fitment".. I think I might end up keeping them... But, I might lean towards Vette iron manifolds or something if they tuck tighter to the block, plus they're stronger to avoid tubular cracking, and the collector is more towards the middle of the block than the front...

Finally, here's the beast...

Holset turbo from an '08 6.7L Cummins. It's called the HE351VGT or HE351VE-VNT, from what I can gather from the intranets (info is very scarce:

-free with minuscule shaft play

-68mm compressor

-.73 exhaust A/R

-oil-lubed journal bearing with water-cooled bearing housing

-variable geometry (duh), Bosch servo controls the turbine cross-sectional area (acts as an internal wastegate on the diesels, that's how they engine brake on the pickups), would need external WG for piece-of-mind

-good for ~600hp on a 6.7L engine @ 3500-4000rpm, I figure 500 for 6.0L @ 6000rpm should be reasonable. I have yet to find a compressor map for it but I have for the HE351VE which I'm hoping is just the dumber non-VNT version of it. Also lots of info for the HE351CW, which sounds similar but came on the 5.9L and I think is a pretty different turbo.

-for my hopes (500hp to the wheels), engine needs to flow about 35lbs/min of air at 10-12psi, and it looks like this is still within the efficient range for this turbo even though it's OEM-spec for 30+psi applications (some of those crazy diesel guys are piggyback-chipping those motors and getting 60+psi out of these turbos)

I put on some JBA tubular headers just to roughly see the fitment. Not sure if I'm gonna use these or not, they have lots of ugly emissions junk on them I'd have to smooth off, not to mention re-weld a V-band flange, as well as them going quite up and out from the block. Hot side tubing might be pretty tight on the pass. side since the turbo would be a "top mount" and the pass. side tube would have to bend down and then back up to merge into the turbine inlet, all right where the coolant lines and lower radiator are

PS... thanks MARK for the usage of your headers for "fitment".. I think I might end up keeping them... But, I might lean towards Vette iron manifolds or something if they tuck tighter to the block, plus they're stronger to avoid tubular cracking, and the collector is more towards the middle of the block than the front...

Finally, here's the beast...

Holset turbo from an '08 6.7L Cummins. It's called the HE351VGT or HE351VE-VNT, from what I can gather from the intranets (info is very scarce:

-free with minuscule shaft play

-68mm compressor

-.73 exhaust A/R

-oil-lubed journal bearing with water-cooled bearing housing

-variable geometry (duh), Bosch servo controls the turbine cross-sectional area (acts as an internal wastegate on the diesels, that's how they engine brake on the pickups), would need external WG for piece-of-mind

-good for ~600hp on a 6.7L engine @ 3500-4000rpm, I figure 500 for 6.0L @ 6000rpm should be reasonable. I have yet to find a compressor map for it but I have for the HE351VE which I'm hoping is just the dumber non-VNT version of it. Also lots of info for the HE351CW, which sounds similar but came on the 5.9L and I think is a pretty different turbo.

-for my hopes (500hp to the wheels), engine needs to flow about 35lbs/min of air at 10-12psi, and it looks like this is still within the efficient range for this turbo even though it's OEM-spec for 30+psi applications (some of those crazy diesel guys are piggyback-chipping those motors and getting 60+psi out of these turbos)

#192

TECH Fanatic

iTrader: (9)

Join Date: Mar 2004

Location: CANADA!

Posts: 1,347

Likes: 0

Received 0 Likes

on

0 Posts

Sorry, but a shitty rod end will wear out. I ran speedways cheapest one for a year, they wore out yes. I ran QA1's race series. And just pulled them apart. No visable wear. Zero play. You get what you pay for. I beat the living **** out of my car(thats why I built it). And they hold up. I've run them on my rear links for years with no issues. Drag racers rarely change them, neither do guys that solo II their cars or open track them. Think about it. at 60-80 a piece for a nice rod end? 8 in the rear on a 4 link, and 2 up front for steering min. maybe 2 for a panhard bar? Its not something a person replaces on a regular basis.

Not trying to **** on anyone. Its just something that could easily get blown out of proportion.

#194

Thanks for the complements guys, just a warning, I'm not going to be in the same city as my car for the next 2 months probably so progress is not gonna be happening

And play nice everyone... A proper none-cheapo heim joint should last a significant time, but I chose to go with Moog joints instead because they had better angular mis-alignment as well as slightly more clearance to the rim (since they aren't dropped as low as a stud & heim joint would need to be). I will eventually run a bumpsteer test when all the weight is back on the front and and all the other steering components are aligned to "aggressive" DD specs, then decid what to do if my bumpsteer is really sheit (crossing fingers).

And play nice everyone... A proper none-cheapo heim joint should last a significant time, but I chose to go with Moog joints instead because they had better angular mis-alignment as well as slightly more clearance to the rim (since they aren't dropped as low as a stud & heim joint would need to be). I will eventually run a bumpsteer test when all the weight is back on the front and and all the other steering components are aligned to "aggressive" DD specs, then decid what to do if my bumpsteer is really sheit (crossing fingers).

#196

The few guys out there that have used these turbo's stand-alone have all used a boost-referenced wastge-type diaphragm & pushrod to actuate the geometry linkage, or just outright bolted/welded it into a permanent position. I'd like think up a slightly more intelligent solution than this. I'm thinking of how I can control the Bosch servo motor and wiring that came with the turbo...

#197

Hey Frojoe, my tranny that came with my LQ9 ended up being an AWD. I am going to put in my th350 now. Is there any thing else I might need to know hooking up the th350? Here is what I read about your experience:

"It bolted up fine to the 6.0L flywheel (no spacers required, but unfortunately I ordered them before I found out I didnt need them) BUT the mounting holes on the flywheel did need some love from a 7/16 drill bit to reduce the bolt circle diameter around ¼ overall. Also, I needed to use 1/8 washers between the torque converter and the flywheel to get it to bolt up. Because the engine was moved forward an inch, I needed to get the driveshaft lengthened, which even if it is a bit pricey is a good thing going from 2.75 x 0.050 to 3 x 0.063. Additionally, I welded 3/8 plate onto the front of the original trans x-member and drilled slots, so that the 1-inch-further-forward trans mount would actually be supported by something!"

Thanks,

Brandon

"It bolted up fine to the 6.0L flywheel (no spacers required, but unfortunately I ordered them before I found out I didnt need them) BUT the mounting holes on the flywheel did need some love from a 7/16 drill bit to reduce the bolt circle diameter around ¼ overall. Also, I needed to use 1/8 washers between the torque converter and the flywheel to get it to bolt up. Because the engine was moved forward an inch, I needed to get the driveshaft lengthened, which even if it is a bit pricey is a good thing going from 2.75 x 0.050 to 3 x 0.063. Additionally, I welded 3/8 plate onto the front of the original trans x-member and drilled slots, so that the 1-inch-further-forward trans mount would actually be supported by something!"

Thanks,

Brandon

#198

TECH Regular

iTrader: (8)

Join Date: Apr 2009

Location: Mount Bethel PA

Posts: 431

Likes: 0

Received 0 Likes

on

0 Posts

The few guys out there that have used these turbo's stand-alone have all used a boost-referenced wastge-type diaphragm & pushrod to actuate the geometry linkage, or just outright bolted/welded it into a permanent position. I'd like think up a slightly more intelligent solution than this. I'm thinking of how I can control the Bosch servo motor and wiring that came with the turbo...

#199

crosstraining...

I believe, as 1989k1500 said, that the LQ9 has the wavy flexplate to mate to the 4L60e, and doesn't come with the spacer that's needed for a TH350 applciation. The LQ4 (I suppose 'cuz it's meant for heavier-duty work) comes with an 4L80e and so it has the flat flexplate with a spacer from the factory. If you're taking the 4L off anyways to put on a TH350, just double-check that this info is right.

73 nova guy...

Yeah it's gonna be tricky, but it'd be cool to be able to slam those vanes shut when the throttle goes WOT for quicker spool

I believe, as 1989k1500 said, that the LQ9 has the wavy flexplate to mate to the 4L60e, and doesn't come with the spacer that's needed for a TH350 applciation. The LQ4 (I suppose 'cuz it's meant for heavier-duty work) comes with an 4L80e and so it has the flat flexplate with a spacer from the factory. If you're taking the 4L off anyways to put on a TH350, just double-check that this info is right.

73 nova guy...

Yeah it's gonna be tricky, but it'd be cool to be able to slam those vanes shut when the throttle goes WOT for quicker spool

#200

[QUOTE=frojoe;12401591]crosstraining...

I believe, as 1989k1500 said, that the LQ9 has the wavy flexplate to mate to the 4L60e, and doesn't come with the spacer that's needed for a TH350 applciation. The LQ4 (I suppose 'cuz it's meant for heavier-duty work) comes with an 4L80e and so it has the flat flexplate with a spacer from the factory. If you're taking the 4L off anyways to put on a TH350, just double-check that this info is right.

Joe~

Thanks I missed 1989k1500's post. I will check this weekend when I get to where my engine/tranny is. Will I just need that spacer then? The 1 you ordered, but didn't need.

Thanks,

Brandon

I believe, as 1989k1500 said, that the LQ9 has the wavy flexplate to mate to the 4L60e, and doesn't come with the spacer that's needed for a TH350 applciation. The LQ4 (I suppose 'cuz it's meant for heavier-duty work) comes with an 4L80e and so it has the flat flexplate with a spacer from the factory. If you're taking the 4L off anyways to put on a TH350, just double-check that this info is right.

Joe~

Thanks I missed 1989k1500's post. I will check this weekend when I get to where my engine/tranny is. Will I just need that spacer then? The 1 you ordered, but didn't need.

Thanks,

Brandon

and keep us up dated

and keep us up dated