Cam only, winter upgrades. Bitch in on a diet

#821

not just idling, driving the car around in 20 and 90*weather. I have a heater, and no trailer remember. Big *** cam 240*.650 on stock cubes and heads. The t56, clutch in from a 7K burnout, and have it settle at idle buy itself ect. I'm gona try SD, and find out for myself like everything else. Be I think I'm alot different them most guys racing and tring to street drive a similar setup.

http://youtu.be/X0EKoRsm65k

http://youtu.be/X0EKoRsm65k

#822

If your any good at tuning, you'll love going SD. One less step to do. Mount your IAT sensor somewhere else too.

I wish Holley would make a "race" version of the Hiram, something with a 5-6" runner for higher rpm and fitment would be even better.

I wish Holley would make a "race" version of the Hiram, something with a 5-6" runner for higher rpm and fitment would be even better.

#823

TECH Fanatic

iTrader: (7)

Join Date: Oct 2005

Location: Western NY

Posts: 1,416

Likes: 0

Received 0 Likes

on

0 Posts

well you tuner sucks!! my car has been ran in -18deg and started up like stock not one surge! cold start in my garage 15-20deg in garage 5 deg outside. It wasn't cranked in a week here i was waiting on wheels to come in.

http://youtu.be/2vbMmNeP_8k

http://youtu.be/2vbMmNeP_8k

The tuners I'm talking about have more experience tuning all sorts of **** than you or anyone in this thread but alright...

#827

made some sturdy alum brackets (thanks BTF rick for welding them) for edelbrock rails to fit the RT, so they will fit my victor too with those brackets. And used some lightweight nylon hose, with the PTFE (?) liner so no gasoline smells Like I noticed on alot of other cars. I think its the shitty 93 with 10% ethenaol I run, or E85 cars do it. (the blue fitting in mock up) Got all black and silver

#828

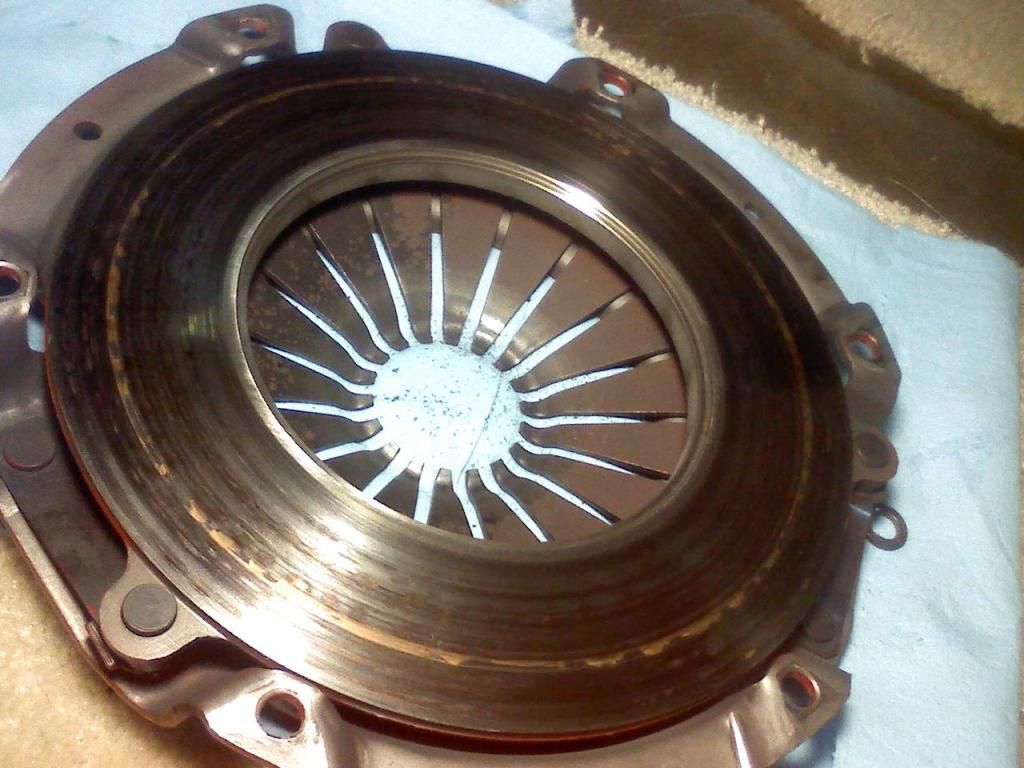

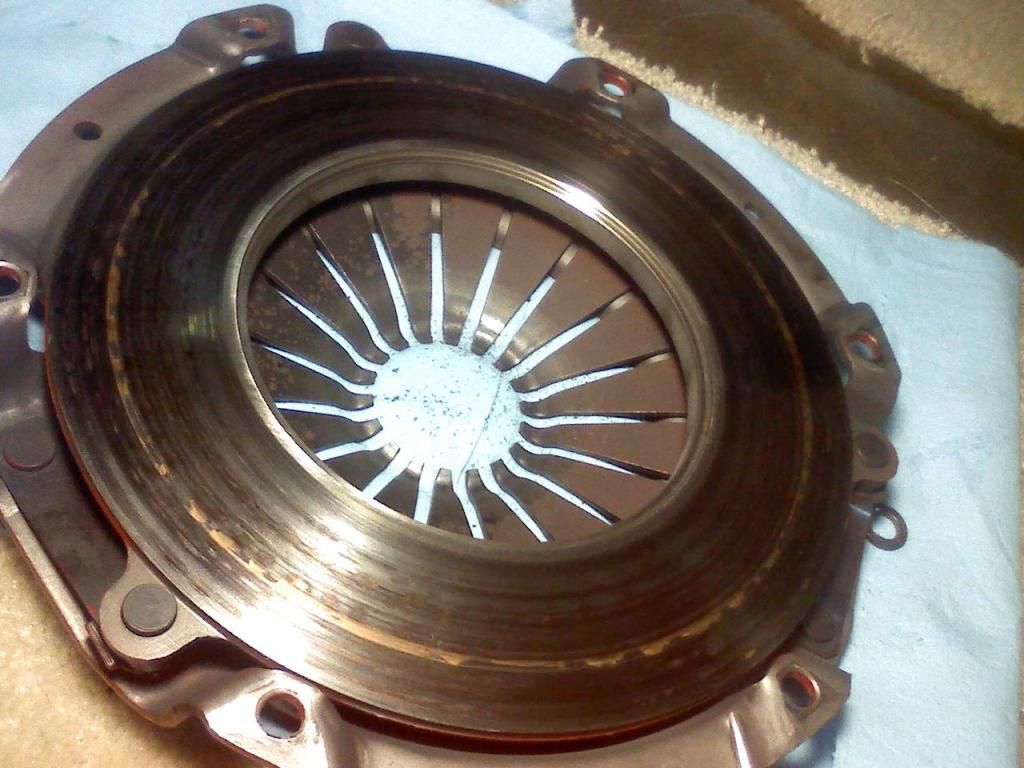

been busy with work, and some other new stuff so not working on the car much. Took the trans and clutch out, after noticed the something acting up. With the bellhousing window I could see something going on looking up in there easy. Disc was rubbing on the float plate strap?

looking into this more, with more apart.. Only wore .010 off the disc so far on this trans going in, 576 miles, the window and open starter/oil filter front keep everything alot cleaner so thatch nice.

outside rubbing

messed up phone pic. haha

took some more left the camar under the car

looking into this more, with more apart.. Only wore .010 off the disc so far on this trans going in, 576 miles, the window and open starter/oil filter front keep everything alot cleaner so thatch nice.

outside rubbing

messed up phone pic. haha

took some more left the camar under the car

#830

11 Second Club

iTrader: (3)

According to Burkhart, it was not a product issue.

https://ls1tech.com/forums/lt1-lt4-m...hootout-3.html

https://ls1tech.com/forums/lt1-lt4-m...hootout-3.html

#831

that's news to me. I guess they weld themselves? hahaha

edit

oh ya, I paid out of pocket to have them cut and welded up soild, and get them re powder coated. ($150) they only had 6 passes, 50 street miles!

sounds normal I guess? Some people stand behind there work, some don't.

edit

oh ya, I paid out of pocket to have them cut and welded up soild, and get them re powder coated. ($150) they only had 6 passes, 50 street miles!

sounds normal I guess? Some people stand behind there work, some don't.

#832

got the clutch dragging, disc run out figured out. The bearing on the input shaft was eating it's self up. I did a 1-2-1 at the track a few weeks ago, and went to a rpm I dont want to know. I heard that can cause the bearing cage to balloon and have it fail, so hopefully this doesn't happen again. Pilot bearing had some wear.. bigger pin gauges fit, but I think that was getting worn for the runout in the shaft inside the trans. Put a new one in. RPM checked out the trans too, said everything looked great. No wear on the faceplates, I'm not driving the car that much not keeping it home. The coating I think is doing alot too.

Tech info: with that bearing input shaft had about .250 of side moment at the pilot bearing dia. And about .035 end play. but after I took the front cover off the most of the roller bearing (damaged) fell over in the races I think then without the cage spacing them correctly. But then the shaft was all over the place, I couldn't see any other wear, or heat marks. But the rollers bearings were black form heat, RPM did the fishing coating on everything even the bearings.

Also took that time to check the actually trans aliment to the crank centerline, off the quick time bellhousing. Useing the t56 front cover bolted on and indicating it off the input shaft bearing hole. Just bolting the bell on and the cover normal, then dont have any noticeable play but gravity pulling them down. I only have abut 5.5 run out (.0055) I think that's pretty good. And I tested pushing them one way or the other (my case 10-11olck) bolting them up and a rubber hammer tap, and can get it within .002. It doesn't take any time and free so just going to take that, try to do that now so its money.

Tech info: with that bearing input shaft had about .250 of side moment at the pilot bearing dia. And about .035 end play. but after I took the front cover off the most of the roller bearing (damaged) fell over in the races I think then without the cage spacing them correctly. But then the shaft was all over the place, I couldn't see any other wear, or heat marks. But the rollers bearings were black form heat, RPM did the fishing coating on everything even the bearings.

Also took that time to check the actually trans aliment to the crank centerline, off the quick time bellhousing. Useing the t56 front cover bolted on and indicating it off the input shaft bearing hole. Just bolting the bell on and the cover normal, then dont have any noticeable play but gravity pulling them down. I only have abut 5.5 run out (.0055) I think that's pretty good. And I tested pushing them one way or the other (my case 10-11olck) bolting them up and a rubber hammer tap, and can get it within .002. It doesn't take any time and free so just going to take that, try to do that now so its money.

#834

Got the tiliton pump, and fittings to set it up. Going to use -6 russle pro classic line, nice and light, should only be about 10-14inch of hose in the system. Think I'm just gonna put a micro switch on the gas peddle so the pump turns on WOT (or close to it). Anyone got a better/simpler way?

Also order the Moroso alum oil pan This week.

This week.

https://ls1tech.com/forums/drag-raci...ter-setup.html

And one 90* and a 45* -10 fitting to fit the bungs off that for the relocated oil filter. Should be here maybe tomarow or mon. Once I get the pan on, I gen get the trans in. Figure out the pump mounting, and make the lines. And get the oil filter setup.

Also order the Moroso alum oil pan

This week.

This week.https://ls1tech.com/forums/drag-raci...ter-setup.html

And one 90* and a 45* -10 fitting to fit the bungs off that for the relocated oil filter. Should be here maybe tomarow or mon. Once I get the pan on, I gen get the trans in. Figure out the pump mounting, and make the lines. And get the oil filter setup.

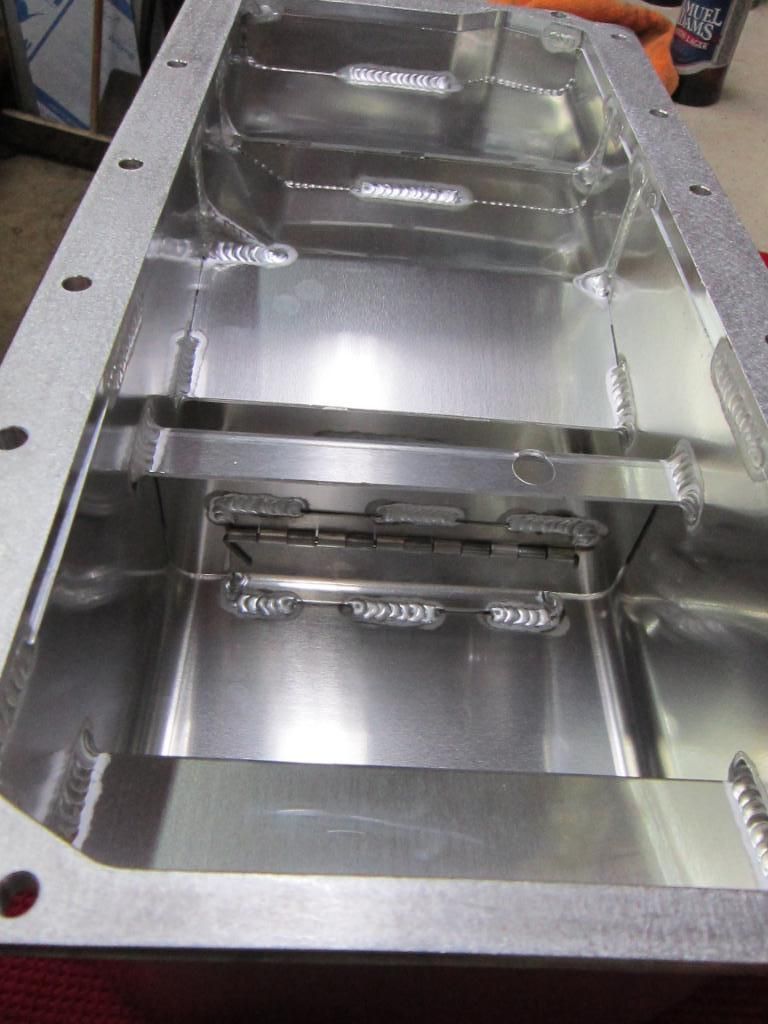

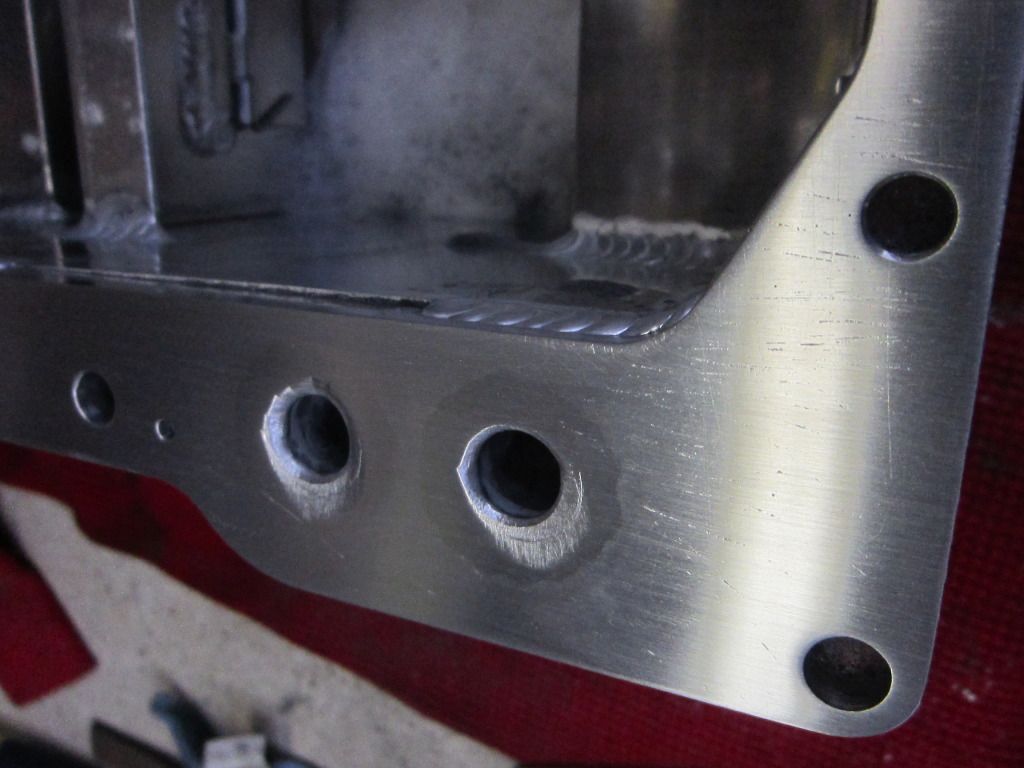

#835

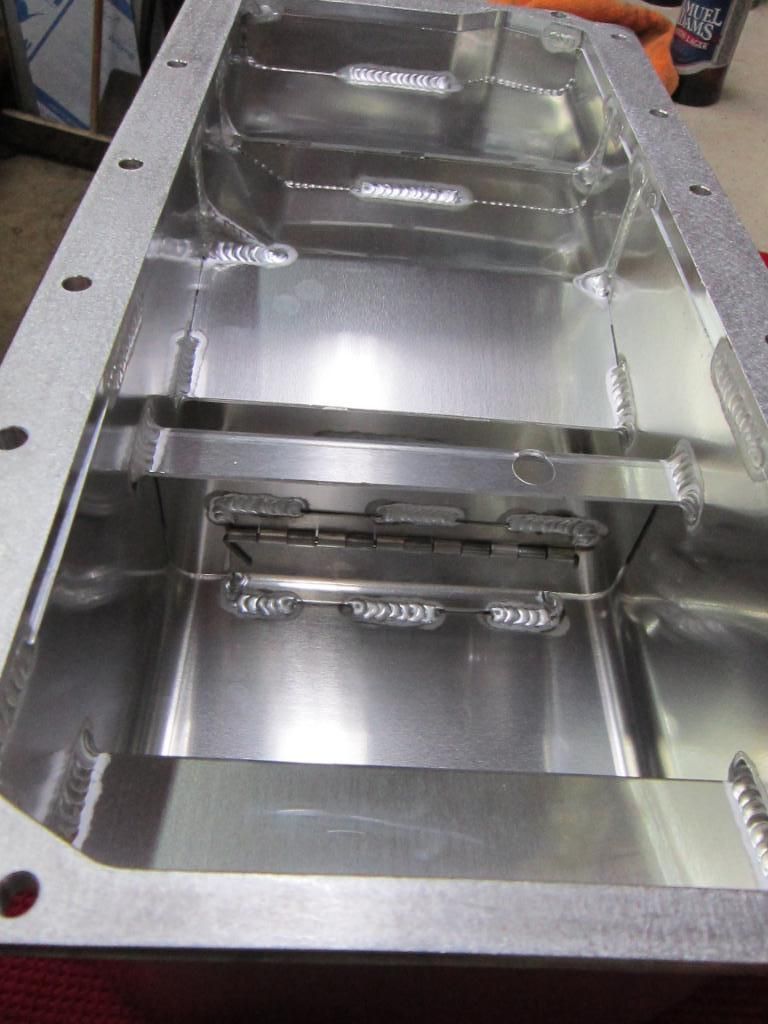

Got the pan the other day, looks really nice, very nice welds for a stock production part anyone can order and get in a few days. And there made in the USA The rail was a little wavy around the -10 an fitting for the oil filter. I got most of the straiten out with some heavy filing, and block sanding.

Going with the one 90* and one 45* fitting in the way to go, there really close to touching, no pushing on or anything. But you can put the 90 inward tight so the hose in close into the pan, and keep the 45 strait and it has space between them. Not sure what tighter then 90, but if someone made a 120* or something that would work good to, then you can run the top line up along the block. or you could run 2 90* if you got a AN Spacer fitting, like a 1inch if then even make them?

Order the oil filter stuff from Jerry Bickle earlier in then week too. Got the CV billet oil filter housing, and 2 -10AN #12ORB (-12 port fitting to -10AN). And a -12port plug (12ORB plug)

Going with the one 90* and one 45* fitting in the way to go, there really close to touching, no pushing on or anything. But you can put the 90 inward tight so the hose in close into the pan, and keep the 45 strait and it has space between them. Not sure what tighter then 90, but if someone made a 120* or something that would work good to, then you can run the top line up along the block. or you could run 2 90* if you got a AN Spacer fitting, like a 1inch if then even make them?

Order the oil filter stuff from Jerry Bickle earlier in then week too. Got the CV billet oil filter housing, and 2 -10AN #12ORB (-12 port fitting to -10AN). And a -12port plug (12ORB plug)

Last edited by studderin; 09-14-2012 at 08:27 AM.

#837

ya Im really picky. Also noticed the trap door flap is barley longer then the baffle slot, wish it had at least a 1/8 longer on the side to cover the slot.

More pics

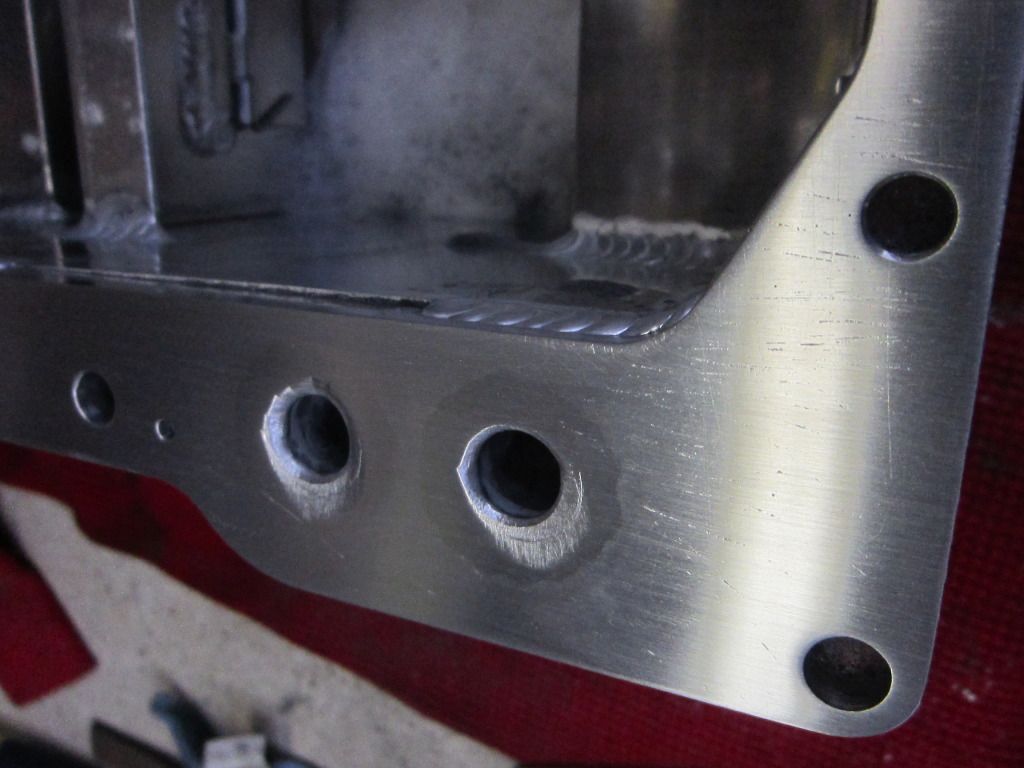

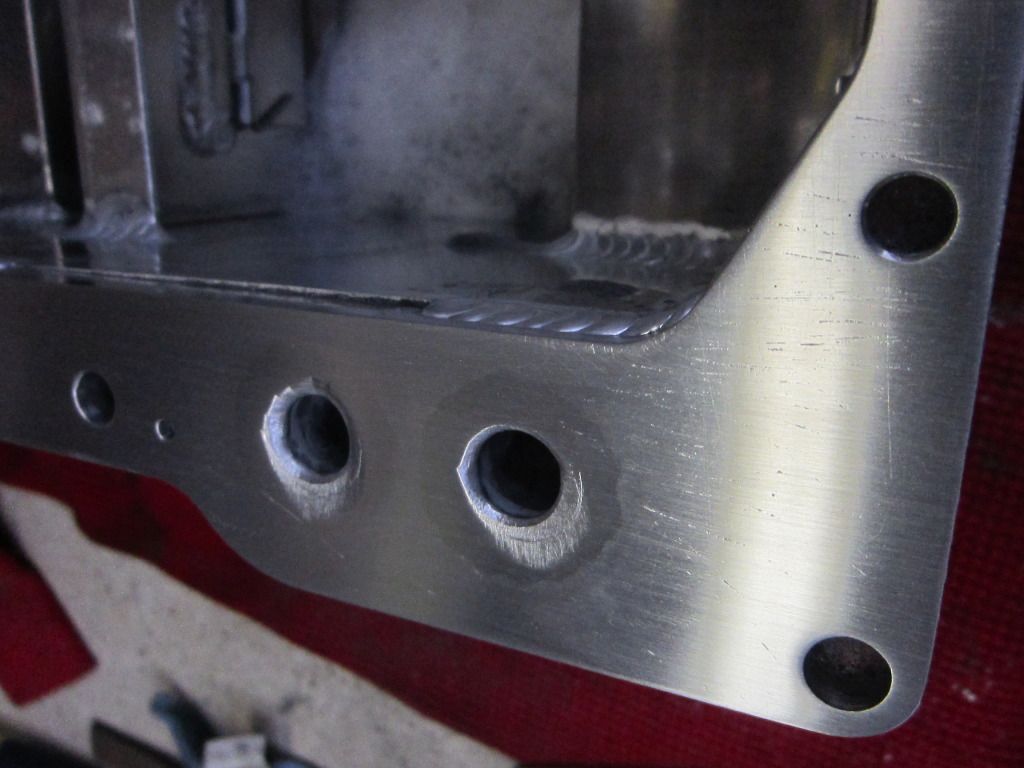

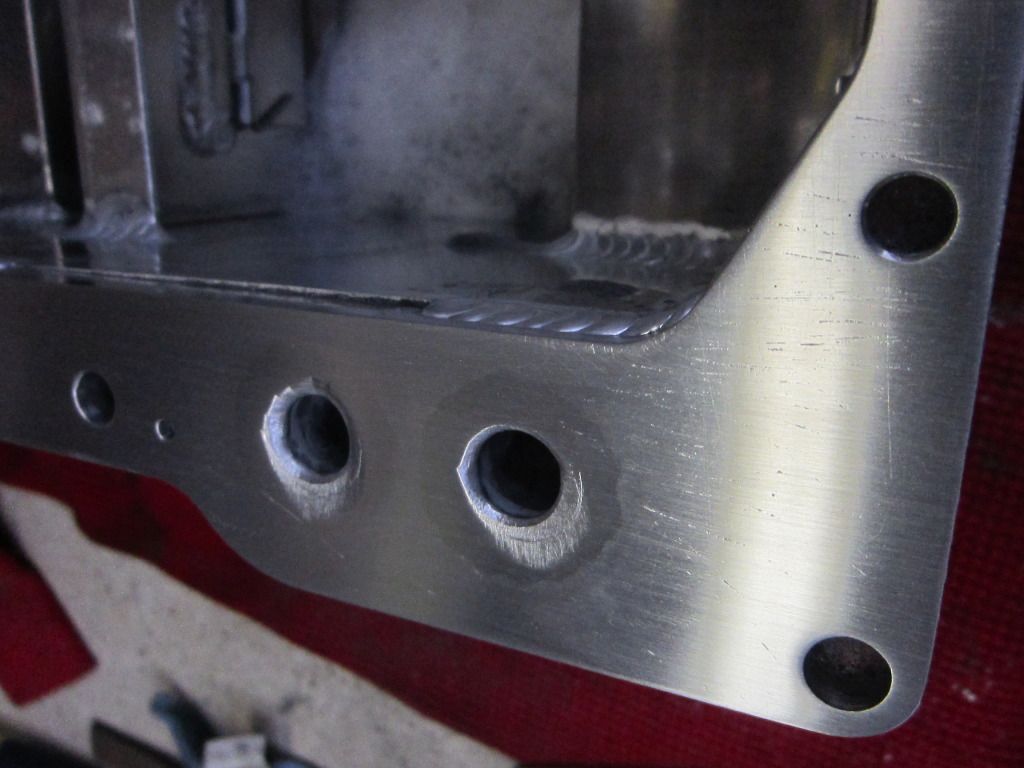

This was how flat the rail was, just but some dye on it and hit it with a flile. You can feel it, and almost see it in the raw alum. I dont know if the oil pan gasket would have sealed to this but didnt want to risk it.

Got most of it out, and flatter. Also notice I drilled the gasket to rivit to this pan super easy to work on. Didn't have any long rivits, just 1/8 x 1/4 or maybe 3/8. But just drilled a 1/8 hole for the rivit, then drilled 1/4 or maybe .3xx from the outside of the rail, maybe 3/4 way thu so the end of the rivit will pop in the bigger drilled hole pocket.

More pics

This was how flat the rail was, just but some dye on it and hit it with a flile. You can feel it, and almost see it in the raw alum. I dont know if the oil pan gasket would have sealed to this but didnt want to risk it.

Got most of it out, and flatter. Also notice I drilled the gasket to rivit to this pan super easy to work on. Didn't have any long rivits, just 1/8 x 1/4 or maybe 3/8. But just drilled a 1/8 hole for the rivit, then drilled 1/4 or maybe .3xx from the outside of the rail, maybe 3/4 way thu so the end of the rivit will pop in the bigger drilled hole pocket.

Last edited by studderin; 09-15-2012 at 03:02 PM.

#840

I changed the pic I posted after a filled and sanded thew rail flatter to a better one.

I still can't get is 100% flat around were the gasket Orings are, you can see were I scribed the ID of the gasket seals.

I dont think I should run it like that ?

djfury

this pan has a full length baffle, and a new pickup tube, that fits in the BACK of the sump. And it has the welded shelf up the back wall. So the oild will stay back there alot better then the stock pan. And it has a baffle in the front, The over hang if you look close at the pics (and the weld marks outside the pan) So under heavy braking thats gona stop the oil from just going up the shallow front getting on the crank. And it has the big plate splitting the sump up with the trap door, so most stays in the back half too. I'll get pics of that, I hope to get it in today.

I think some locals want the improved baffle, or someone wants my pan did did a swap running the truck pan still. I have a ton of **** I need to sell. Also got the oil filter stuff, Glad I spend the extra moneu and got good stuff, (CV filter mount, Good fitting form jerry bickel) the stuff is NICE. No burrs, great finishes, threads are smooth and tight, lots of little things you can see went into it just testing fitting parts.

nasty-

I have the lower part of the quicktime block plate I can bolt back on. But think I'm just gona leave it open.

I still can't get is 100% flat around were the gasket Orings are, you can see were I scribed the ID of the gasket seals.

I dont think I should run it like that ?

djfury

this pan has a full length baffle, and a new pickup tube, that fits in the BACK of the sump. And it has the welded shelf up the back wall. So the oild will stay back there alot better then the stock pan. And it has a baffle in the front, The over hang if you look close at the pics (and the weld marks outside the pan) So under heavy braking thats gona stop the oil from just going up the shallow front getting on the crank. And it has the big plate splitting the sump up with the trap door, so most stays in the back half too. I'll get pics of that, I hope to get it in today.

I think some locals want the improved baffle, or someone wants my pan did did a swap running the truck pan still. I have a ton of **** I need to sell. Also got the oil filter stuff, Glad I spend the extra moneu and got good stuff, (CV filter mount, Good fitting form jerry bickel) the stuff is NICE. No burrs, great finishes, threads are smooth and tight, lots of little things you can see went into it just testing fitting parts.

nasty-

I have the lower part of the quicktime block plate I can bolt back on. But think I'm just gona leave it open.

Last edited by studderin; 09-15-2012 at 02:53 PM.