Cam only, winter upgrades. Bitch in on a diet

#862

I notice on the oil pick up you welded a small strip of metal along the side of the strap. Were it bolts to the main cap. That was a good idea. Mine broke right there and caused the end of the tube to vibrate so bad it fell off.

I also notice you cut the windage tray out right there so it sits flat on the cap and not the tray.

It is coming along nicely.

I also notice you cut the windage tray out right there so it sits flat on the cap and not the tray.

It is coming along nicely.

ya that side strip came welded on, was a little tight fitting in the windage tray square cutout, so that makes sense they added it recently. then just need to make the opening a little bigger for it now. I could push and tap it in, but didnt what to force anything doing it around the Kmeber with the oil pump on and everything on the front of the motor. I didn't have to change anything for it to fit on the cap? Just the pickup brace arm went to that pain stud.

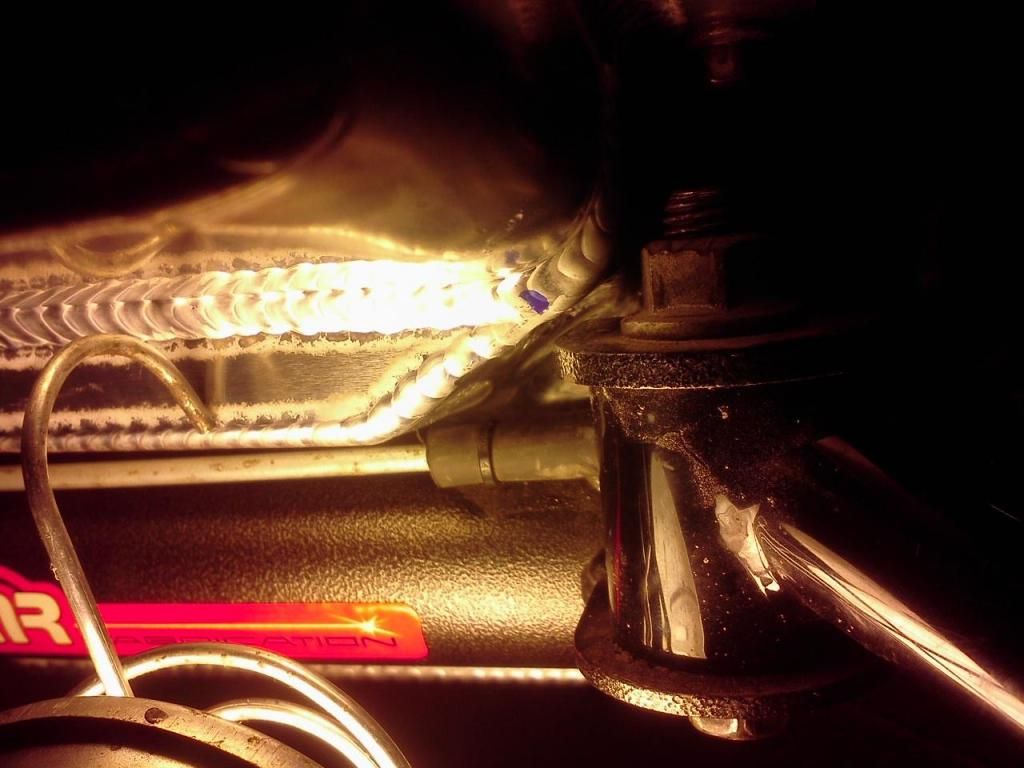

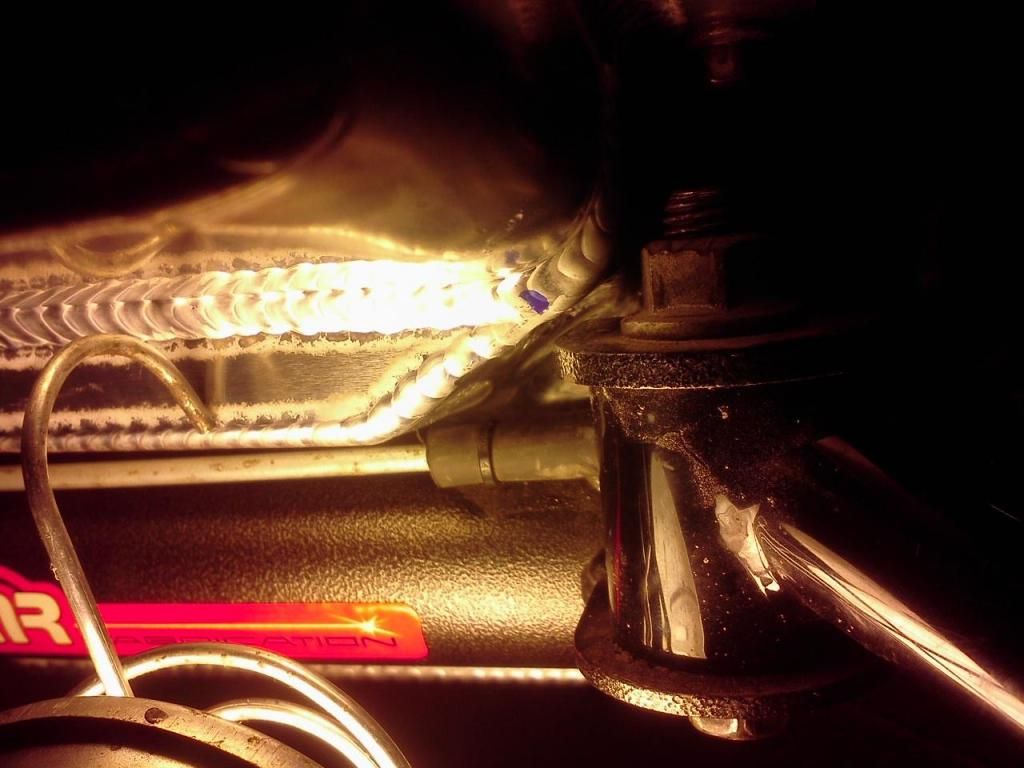

How flat was your rail around the AN oil feed in the rear coner? The final "looks" pass then did around them on the outside to blend it nice to the rails weld, but alot of heat in the rail, and wapt it pretty good as you could see.

Also noticed on final wash the rear baffle, is welded maybe .080 from the side, and a few spots, but the corners were open. Maybe for oil to drain, but its already past the crank and rods and it tipped to flow around it. But the open corners let a lot of oil flow right thu and around the baffle. tipping the pan back with water in it, it got thu faster then the baffle dammed it back from climbing and flowing out the back. So next time its out I'm gona weld them corners up fully, or do something about that. Its still alot better then stock, but didnt work as good as I thought? check that out.

How much oil you guys running in this pan?

#863

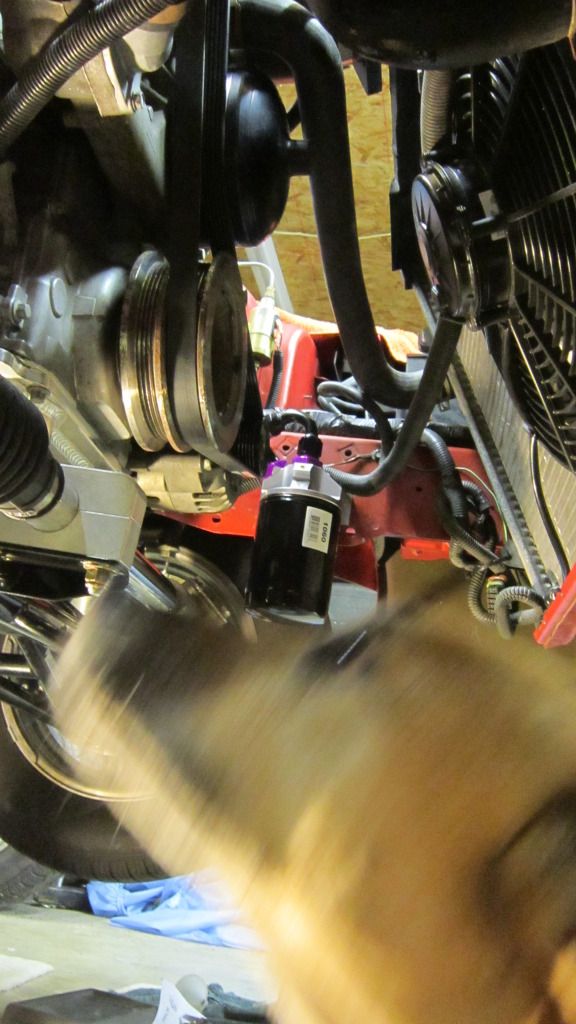

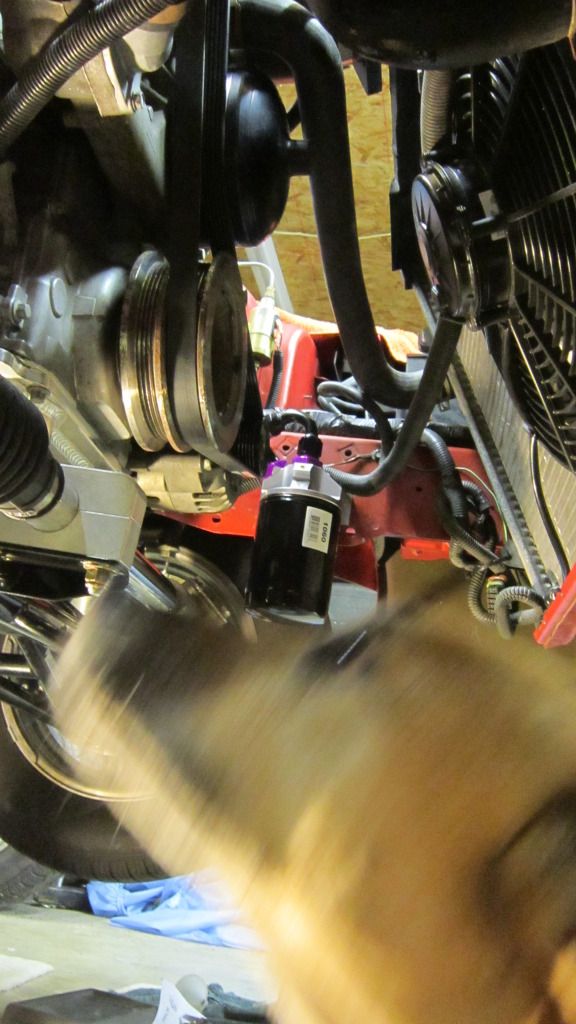

sloted the holes a little, fits great on the ABS holes. And I can move it back if need be when I get a better fit rack setup.

-10 Hose earlsm=, bought 6ft, there about 30-32 long to the fittings, have about 10-12" left

fittings- black earls -10

2) 90*

1) 45*

1) 120* (or its a 130?)

Or you could do both 90s on the pan if you get that -10 longer fitting (-10 spacer)

http://mrparts.com.au/index.php?rout...roduct_id=2900

-10 Hose earlsm=, bought 6ft, there about 30-32 long to the fittings, have about 10-12" left

fittings- black earls -10

2) 90*

1) 45*

1) 120* (or its a 130?)

Or you could do both 90s on the pan if you get that -10 longer fitting (-10 spacer)

http://mrparts.com.au/index.php?rout...roduct_id=2900

Last edited by studderin; 10-01-2012 at 11:21 AM.

#865

I dont think you can run a setup like this with the stock pan, without some cutting and welding. Are you thinking of the oil cooler block I've seen the bolts to the little U shape passage on the side over the filter? Those you can run AN lines for oil lines off off, but you still run the filter on the pan. I can't think of anything you would use to run lines off the stock pan to a filter?

Trans pump works great,wired off the WOT switch on the pedal Key on or off.

Moroso said the pan holds 6pts, I filled up filter (1060), they hold just under 1qt, and I figure the lines hold 1/2 a qt. So gona run 7.5 qts, and that comes out to about the bottme of the range marked out on the stock dipstick.

More bad news, the pan is leaking Out of the rear bolt. Its coming from the spot face that cut the weld away off the rail. Its running down the back and drips a few drops. So that's awesome news!

Out of the rear bolt. Its coming from the spot face that cut the weld away off the rail. Its running down the back and drips a few drops. So that's awesome news!

And it was hitting the driver side steering rack mount. I have good poly mounts, the bolt holes are still soild and tight in the mounts, and Kmeber is a BMR with stock rack mounts. It started to cut a gash in the pan. Glad tommy from new era noticed it was touching. So we pulled the alt., jacked the motor up again, and I used a 1/2 round brass bar to get the pan to start to dent there (it was a corner so solid there) BFH, and some prying with the bar, and got some room between the pan and rack mount. Nothing like hamming a dent in you $680 sheetmetal alum oil pan with no miles on it yet that leaks oil

Trans pump works great,wired off the WOT switch on the pedal Key on or off.

Moroso said the pan holds 6pts, I filled up filter (1060), they hold just under 1qt, and I figure the lines hold 1/2 a qt. So gona run 7.5 qts, and that comes out to about the bottme of the range marked out on the stock dipstick.

More bad news, the pan is leaking

Out of the rear bolt. Its coming from the spot face that cut the weld away off the rail. Its running down the back and drips a few drops. So that's awesome news!

Out of the rear bolt. Its coming from the spot face that cut the weld away off the rail. Its running down the back and drips a few drops. So that's awesome news!

And it was hitting the driver side steering rack mount. I have good poly mounts, the bolt holes are still soild and tight in the mounts, and Kmeber is a BMR with stock rack mounts. It started to cut a gash in the pan. Glad tommy from new era noticed it was touching. So we pulled the alt., jacked the motor up again, and I used a 1/2 round brass bar to get the pan to start to dent there (it was a corner so solid there) BFH, and some prying with the bar, and got some room between the pan and rack mount. Nothing like hamming a dent in you $680 sheetmetal alum oil pan with no miles on it yet that leaks oil

Last edited by studderin; 10-02-2012 at 09:52 PM.

#868

ther all diffent. the master I think one is m12 the other in m11 so the facotry cannot hook them up wrong. And I think you need m10 for the wheel flex lines if you have stock brakes and the stock rubber flex lines running to them. I used 3/16 brake lines, and normal double flair. id go to the store and get a few of the adopter fitting (metric to 3/16) to be sure, and return the ones you dont need. But there all 3 different sizes for the stock master ports, and the front flex lines

#870

this pan sucks, I wish I kept the stock one. I hav a ton of time ******* with this POS, missed INDY thinking I hurt the motor. And a track event today I would have won a nice trophy I won in the spring event. Next time I have a chance to get it off I'd throwing this POS out.

The pan still drips out of the rear bolts, its still about 1/8 away for hitting my stock rack mounts after hammering the **** to dent it there.

update is........... 2 days before everyone was going to leave for indy I test drive the car, cruising, around pulling some gears, doing burnouts on the cold roads. Smell some oil so go home to check it.

It pushed the dipstick out a bit and pumped oil all over the motor thats never good. (that happens when you have a piston knocked the land off, cranks rings, melded, or something bad) the plugs looked great, its not got any dead holes

thats never good. (that happens when you have a piston knocked the land off, cranks rings, melded, or something bad) the plugs looked great, its not got any dead holes did a compression test, 185-190... 7 cranks like a 180 thats the weakest cly but its not hurt or anything. spend 1-2 hours cleaning up all the oil mess all over the coils, intake, down the head, all over the engine bay

did a compression test, 185-190... 7 cranks like a 180 thats the weakest cly but its not hurt or anything. spend 1-2 hours cleaning up all the oil mess all over the coils, intake, down the head, all over the engine bay

No idea why it did that the motor is fine I think. Noticed the slave is leaking brake fluid in the bell housing and the quick connect is leaking? The res. was low and fuild so it is leaking. thats not going to drive to indy like that. Moroso says the pan holds 6 qts. So I think it might be over filled thinking I had put 8 in, but I could have put 9 in? So I drain all the oil from the pan back into the qts. It had just about 5 7/8, I spilled a little. And it pumped out alot more then that so it did have more then 6 in it. But I put that back and a little, so I know know it really has 6 qts in it. BTW thats right between the last D and "ADD" and the start of the XXXXX range. The lines and filter don't drain back into the pan with this setup, I noticed it gets oil pressure alot faster on start up now with that filter setup too, the lines and filter stay fill of oil. The catch can was ok, I would think it would have filled up with oil if it was pressurizing the motor. pulled it all off checked the lines, all clear, they were hooked up right, PCV valves working right. Checked some other stuff, found nothing wrong.

It was dark and raining to test drive it more. I was late had to work then next day early and leave after work to go to indy so went home. Ended up having to work more then planned. but test drove it and it push the dip stick again . So not taking the car, hitched a ride there with bill trovoto. messed around got 2stroke racers car working good at indy, but I wish I had the car. Anyway back home messed around a ton more on this. did a leak down, its fine. Motors alot better then I thought, with warm pulled the valve train and a few springs to test (looked good, stock rockers and guilds fine over .650 lift) 100psi into the cly most leaked to 90-95psi. 7/8 were lower 7 was only 85psi. But the motor is sealed up, Its gotta be the oil pan, thats all I've changed. I noticed when I put the windage try on it, it "clears" a 4.1 stroke moroso says. Well my 3.6 stock motor junk is way away from that, and not really close to the crack like I would like. So thinking I might have more oil flying around then the stock windage tray that fits closer? The dyno is going to the new shop and setup yet to test this pan. or test crankcase pressuer easy WOT under load. So I make this test junk the other day to see it its pressurizing the crank case or just getting oil up the dipstick tube some how???

. So not taking the car, hitched a ride there with bill trovoto. messed around got 2stroke racers car working good at indy, but I wish I had the car. Anyway back home messed around a ton more on this. did a leak down, its fine. Motors alot better then I thought, with warm pulled the valve train and a few springs to test (looked good, stock rockers and guilds fine over .650 lift) 100psi into the cly most leaked to 90-95psi. 7/8 were lower 7 was only 85psi. But the motor is sealed up, Its gotta be the oil pan, thats all I've changed. I noticed when I put the windage try on it, it "clears" a 4.1 stroke moroso says. Well my 3.6 stock motor junk is way away from that, and not really close to the crack like I would like. So thinking I might have more oil flying around then the stock windage tray that fits closer? The dyno is going to the new shop and setup yet to test this pan. or test crankcase pressuer easy WOT under load. So I make this test junk the other day to see it its pressurizing the crank case or just getting oil up the dipstick tube some how???

And after going WOT over 4-5K rpms you can watch clean soild oil getting pumped, pulsing up the dipstick tube No oil mist or blow by smoke or anything. I let off before it got out the tube and all over the car, and it went right back down. No pics WOT LOL, but it got up to the duct tape, none on the car.

No oil mist or blow by smoke or anything. I let off before it got out the tube and all over the car, and it went right back down. No pics WOT LOL, but it got up to the duct tape, none on the car.

And I just looked at some pics I took, when I put the pan in a few weeks ago for grinding the windage tray to clear the dipstick.

thats little MF' louver is right across form the tube, thats got to be it!!!

Stock tray has the louvers stamped going IN in on that side of the windage tray. So there not going to be directing oil to the end (opening) of the dipstick So I guess it good I found it, and the motor is OK like everything checks out. I'm just gona zip tie the dipstick down for world cup coming up. I have to take the trans out AGAIN, to change the slave and the line off the master. But don't think I want to change the pan back.

So I guess it good I found it, and the motor is OK like everything checks out. I'm just gona zip tie the dipstick down for world cup coming up. I have to take the trans out AGAIN, to change the slave and the line off the master. But don't think I want to change the pan back.

Anyone think I should, if the moroso dose makes more power, or not?

The pan still drips out of the rear bolts, its still about 1/8 away for hitting my stock rack mounts after hammering the **** to dent it there.

update is........... 2 days before everyone was going to leave for indy I test drive the car, cruising, around pulling some gears, doing burnouts on the cold roads. Smell some oil so go home to check it.

It pushed the dipstick out a bit and pumped oil all over the motor

thats never good. (that happens when you have a piston knocked the land off, cranks rings, melded, or something bad) the plugs looked great, its not got any dead holes

thats never good. (that happens when you have a piston knocked the land off, cranks rings, melded, or something bad) the plugs looked great, its not got any dead holes did a compression test, 185-190... 7 cranks like a 180 thats the weakest cly but its not hurt or anything. spend 1-2 hours cleaning up all the oil mess all over the coils, intake, down the head, all over the engine bay

did a compression test, 185-190... 7 cranks like a 180 thats the weakest cly but its not hurt or anything. spend 1-2 hours cleaning up all the oil mess all over the coils, intake, down the head, all over the engine bay

No idea why it did that the motor is fine I think. Noticed the slave is leaking brake fluid in the bell housing and the quick connect is leaking? The res. was low and fuild so it is leaking. thats not going to drive to indy like that. Moroso says the pan holds 6 qts. So I think it might be over filled thinking I had put 8 in, but I could have put 9 in? So I drain all the oil from the pan back into the qts. It had just about 5 7/8, I spilled a little. And it pumped out alot more then that so it did have more then 6 in it. But I put that back and a little, so I know know it really has 6 qts in it. BTW thats right between the last D and "ADD" and the start of the XXXXX range. The lines and filter don't drain back into the pan with this setup, I noticed it gets oil pressure alot faster on start up now with that filter setup too, the lines and filter stay fill of oil. The catch can was ok, I would think it would have filled up with oil if it was pressurizing the motor. pulled it all off checked the lines, all clear, they were hooked up right, PCV valves working right. Checked some other stuff, found nothing wrong.

It was dark and raining to test drive it more. I was late had to work then next day early and leave after work to go to indy so went home. Ended up having to work more then planned. but test drove it and it push the dip stick again

. So not taking the car, hitched a ride there with bill trovoto. messed around got 2stroke racers car working good at indy, but I wish I had the car. Anyway back home messed around a ton more on this. did a leak down, its fine. Motors alot better then I thought, with warm pulled the valve train and a few springs to test (looked good, stock rockers and guilds fine over .650 lift) 100psi into the cly most leaked to 90-95psi. 7/8 were lower 7 was only 85psi. But the motor is sealed up, Its gotta be the oil pan, thats all I've changed. I noticed when I put the windage try on it, it "clears" a 4.1 stroke moroso says. Well my 3.6 stock motor junk is way away from that, and not really close to the crack like I would like. So thinking I might have more oil flying around then the stock windage tray that fits closer? The dyno is going to the new shop and setup yet to test this pan. or test crankcase pressuer easy WOT under load. So I make this test junk the other day to see it its pressurizing the crank case or just getting oil up the dipstick tube some how???

. So not taking the car, hitched a ride there with bill trovoto. messed around got 2stroke racers car working good at indy, but I wish I had the car. Anyway back home messed around a ton more on this. did a leak down, its fine. Motors alot better then I thought, with warm pulled the valve train and a few springs to test (looked good, stock rockers and guilds fine over .650 lift) 100psi into the cly most leaked to 90-95psi. 7/8 were lower 7 was only 85psi. But the motor is sealed up, Its gotta be the oil pan, thats all I've changed. I noticed when I put the windage try on it, it "clears" a 4.1 stroke moroso says. Well my 3.6 stock motor junk is way away from that, and not really close to the crack like I would like. So thinking I might have more oil flying around then the stock windage tray that fits closer? The dyno is going to the new shop and setup yet to test this pan. or test crankcase pressuer easy WOT under load. So I make this test junk the other day to see it its pressurizing the crank case or just getting oil up the dipstick tube some how???

And after going WOT over 4-5K rpms you can watch clean soild oil getting pumped, pulsing up the dipstick tube

No oil mist or blow by smoke or anything. I let off before it got out the tube and all over the car, and it went right back down. No pics WOT LOL, but it got up to the duct tape, none on the car.

No oil mist or blow by smoke or anything. I let off before it got out the tube and all over the car, and it went right back down. No pics WOT LOL, but it got up to the duct tape, none on the car.

And I just looked at some pics I took, when I put the pan in a few weeks ago for grinding the windage tray to clear the dipstick.

thats little MF' louver is right across form the tube, thats got to be it!!!

Stock tray has the louvers stamped going IN in on that side of the windage tray. So there not going to be directing oil to the end (opening) of the dipstick

Anyone think I should, if the moroso dose makes more power, or not?

Last edited by studderin; 10-22-2012 at 01:28 AM.

#871

Last week orderd a set of these rims for track wheels last week to run DS2s and 3055s.

Champion speed series in black. non beadlock

http://www.cwibeadlock.com/NBL%20Speed%20Series.htm

thought about the cab5. but my non narrowed rearend that style rim need alot of lip to look good on the rear. I didn't like how it would look (like running front tires on the rear). I wanted a diffrent wheel them my weld/prostars. So wanted black, not not all black on SOM looks kinda getto. So this have alot machined alum on the center, and the polished barrel should look good still.

15x3.5--8.5 lbs. $260 each

15x10--15.5 lbs $280 eash shipping is about $70 to NY form CA

Not the lightest rim, But all front 15x3.5 are about 8 pounds. The high end welds, are about 7.5ish but cost 2x these. Them and holshotsare about 11 pounds for rears 15x10s but cost alot more. And only come in 7/8 BS amounts. champion can do anything in 1/4 steups. And you can get the fronts with a little more BS to tuck a little more then prostars/greag welds.

Champion speed series in black. non beadlock

http://www.cwibeadlock.com/NBL%20Speed%20Series.htm

thought about the cab5. but my non narrowed rearend that style rim need alot of lip to look good on the rear. I didn't like how it would look (like running front tires on the rear). I wanted a diffrent wheel them my weld/prostars. So wanted black, not not all black on SOM looks kinda getto. So this have alot machined alum on the center, and the polished barrel should look good still.

15x3.5--8.5 lbs. $260 each

15x10--15.5 lbs $280 eash shipping is about $70 to NY form CA

Not the lightest rim, But all front 15x3.5 are about 8 pounds. The high end welds, are about 7.5ish but cost 2x these. Them and holshotsare about 11 pounds for rears 15x10s but cost alot more. And only come in 7/8 BS amounts. champion can do anything in 1/4 steups. And you can get the fronts with a little more BS to tuck a little more then prostars/greag welds.

#872

Hey Studderin, bad luck with the pan........ You have or should I say, had, a very hasstle free setup. I would personally be inclined to go back with the stock pan, because of the small gain in power for a larger gain in problems. Just my two cents!

Its a shame you missed indy........ but Im diggin the new wheels man!

Its a shame you missed indy........ but Im diggin the new wheels man!

#873

Ya, I found 2 smaller Orings I put on my dipstick that tighten the fit up, and I put a carb spring to the coil bracket to hold it down. I have a new slave should be he this week, and a master clutch line to change out, So the trans will be out again. I can put the stock back. But I think Im gonna wait till winter pull the moroso, fix the hammered spot, fix the rear bolts, and move the windage tray closer, to free some more HP. And I can weld a little tap or something to block the end of the dipstick better. Or V pinch the loved closed in that one spot. That was just a huge PITA to find out what was going on. I probably have 10-15 hours, into re doing brand new ****. I just hope others don't have;t to deal with all that.

I'm hoping the wheel get done anyday now, but I might have to get them 2nd day air ($250) or something if that can't get out this week.

working on some new stuff too, thats gona make some more power.

WFC all motor this year lowerd the weight a little, I might have have to stack plates this year

8-Cylinder Engines – Chevy LS series

Engine: LS1, LS2, LS3, LS6, and LS7 series blocks permitted. No aftermarket blocks are permitted. Internal engine modifications are prohibited except for aftermarket camshaft, hydraulic lifters,

valve train, and overbore (See chart below for max CID).

Description: This is a cam only class with bolt-ons for LS1, LS2, LS3, and LS6 cars. LS7 are limited to bolt-ons only.

Bolt-Ons: External bolt-on parts are permitted.

Camshaft: LS1, LS2, LS3, and LS6 cars are permitted to run any hydraulic camshaft. LS7cars must run OEM camshaft and OEM valve train.

Induction: Engine must be EFI. All OEM intakes are permitted. The only aftermarket intakes permitted are: BBK intakes, Typhoon intakes, and Fast 78mm, 90mm, 92mm, and 102mm intakes.

Cylinder Heads: Un-Ported as cast cylinder heads only, porting prohibited. Any valve job is permitted. No milling of cylinder head. OEM cylinder heads only are permitted with the following casting

numbers: 241, 243, 317, 706, 799, 853, 862, 8452.

Power Adders: Turbochargers, Superchargers, and Nitrous Oxide are prohibited. All nitrous bottles and solenoids must be removed from car and nitrous nozzles must be capped.

Driveline Block Cylinder Heads Max Displacement Car & Driver Minimum Weight

Straight Axle or IRS LS1 or LS6 LS1 or LS6 heads 348ci. Max 3000 lbs.

Straight Axle or IRS LS1 or LS6 LS2 heads 348ci. Max 3050 lbs.

Straight Axle or IRS LS1 or LS6 LS3 heads 348ci. Max 3200 lbs.

Straight Axle or IRS LS2 LS1 or LS6 heads 366ci. Max 3100 lbs.

Straight Axle or IRS LS2 LS2 heads 366ci. Max 3150 lbs.

Straight Axle or IRS LS2 LS3 heads 366ci. Max 3300 lbs.

Straight Axle or IRS LS3 LS1, LS2, LS3, or LS6 heads 380ci. Max 3300 lbs.

IRS Only LS7 LS7 heads 427ci. Max 3300 lbs.

* LS1, LS2, LS3, and LS6 cars with manual transmission: Deduct 100 lbs.

* LS1, LS2, LS3, and LS6 cars with IRS: Deduct 50 lbs.

I'm hoping the wheel get done anyday now, but I might have to get them 2nd day air ($250) or something if that can't get out this week.

working on some new stuff too, thats gona make some more power.

WFC all motor this year lowerd the weight a little, I might have have to stack plates this year

8-Cylinder Engines – Chevy LS series

Engine: LS1, LS2, LS3, LS6, and LS7 series blocks permitted. No aftermarket blocks are permitted. Internal engine modifications are prohibited except for aftermarket camshaft, hydraulic lifters,

valve train, and overbore (See chart below for max CID).

Description: This is a cam only class with bolt-ons for LS1, LS2, LS3, and LS6 cars. LS7 are limited to bolt-ons only.

Bolt-Ons: External bolt-on parts are permitted.

Camshaft: LS1, LS2, LS3, and LS6 cars are permitted to run any hydraulic camshaft. LS7cars must run OEM camshaft and OEM valve train.

Induction: Engine must be EFI. All OEM intakes are permitted. The only aftermarket intakes permitted are: BBK intakes, Typhoon intakes, and Fast 78mm, 90mm, 92mm, and 102mm intakes.

Cylinder Heads: Un-Ported as cast cylinder heads only, porting prohibited. Any valve job is permitted. No milling of cylinder head. OEM cylinder heads only are permitted with the following casting

numbers: 241, 243, 317, 706, 799, 853, 862, 8452.

Power Adders: Turbochargers, Superchargers, and Nitrous Oxide are prohibited. All nitrous bottles and solenoids must be removed from car and nitrous nozzles must be capped.

Driveline Block Cylinder Heads Max Displacement Car & Driver Minimum Weight

Straight Axle or IRS LS1 or LS6 LS1 or LS6 heads 348ci. Max 3000 lbs.

Straight Axle or IRS LS1 or LS6 LS2 heads 348ci. Max 3050 lbs.

Straight Axle or IRS LS1 or LS6 LS3 heads 348ci. Max 3200 lbs.

Straight Axle or IRS LS2 LS1 or LS6 heads 366ci. Max 3100 lbs.

Straight Axle or IRS LS2 LS2 heads 366ci. Max 3150 lbs.

Straight Axle or IRS LS2 LS3 heads 366ci. Max 3300 lbs.

Straight Axle or IRS LS3 LS1, LS2, LS3, or LS6 heads 380ci. Max 3300 lbs.

IRS Only LS7 LS7 heads 427ci. Max 3300 lbs.

* LS1, LS2, LS3, and LS6 cars with manual transmission: Deduct 100 lbs.

* LS1, LS2, LS3, and LS6 cars with IRS: Deduct 50 lbs.

#874

oh ya, getting some good DA afco shocks, new coils and the other hardware from madman on the way. Talked a bunch of the phone, got everything spec'd out, and valved for my weight, and power ect..\

And got hes tuneup and help now

tomight worked on making a new lid, for the new intake and TB setup

And got hes tuneup and help now

tomight worked on making a new lid, for the new intake and TB setup

Last edited by studderin; 10-25-2012 at 10:39 PM.

#877

lid is made, about a 1/16 from hitting the hood, or it is touching a little. But it fits really nice. Hoping to get it welded up tomarrow

And shocks and everything came today, 1 day sooner then said. MADMAN is great.

I ordered them tues.

And shocks and everything came today, 1 day sooner then said. MADMAN is great.

I ordered them tues.

Last edited by studderin; 11-14-2012 at 02:45 PM.

#878

Me likes that lid!!!

I picked up 8-10rwhp with this setup on my heads cam 102/102...back to back testing vs a 98mm FTP lid...not sure how much you will get with a cam only car but i bet it will still be a good amount

this would be a good setup too and less modifications

https://ls1tech.com/forums/16796639-post96.html

https://ls1tech.com/forums/16803967-post109.html

Last edited by chrs1313; 10-26-2012 at 12:33 AM.

#880

300, cars heavy. haha

madman gave me everything with the front shock setup, not just stocked boxed shocks on a shelf, and springs. He speced everything out, I got 275springs, and the valving it has a special note on the spec sheet, I haven't read all of it yet. New bearing kit (free), spring mounts,and lots of stuff with the afcos. Best is the track tech support

this is the bellow used on the other newera intake. It makes more power then any other style one tested, and I talked to mike about it, I remembered a little helping some of the pro type ones, Without any hood space or length. On how close you can have what, can be. and were you need to have what, and how much radius. You have some room to improve that, but not cramped in the lid. I dont think you can ever run a filter. You your bending it or something? Try something with more raduis.

I want something to drive around with, in the rain and dirt roads. Still uses the stock filter, Old setup gained nothing at the track pulling the filter out.

Plus my intake is alot taller then that. Stock lid isn't even close.

madman gave me everything with the front shock setup, not just stocked boxed shocks on a shelf, and springs. He speced everything out, I got 275springs, and the valving it has a special note on the spec sheet, I haven't read all of it yet. New bearing kit (free), spring mounts,and lots of stuff with the afcos. Best is the track tech support

this is the bellow used on the other newera intake. It makes more power then any other style one tested, and I talked to mike about it, I remembered a little helping some of the pro type ones, Without any hood space or length. On how close you can have what, can be. and were you need to have what, and how much radius. You have some room to improve that, but not cramped in the lid. I dont think you can ever run a filter. You your bending it or something? Try something with more raduis.

I want something to drive around with, in the rain and dirt roads. Still uses the stock filter, Old setup gained nothing at the track pulling the filter out.

Plus my intake is alot taller then that. Stock lid isn't even close.

Last edited by studderin; 10-26-2012 at 07:45 AM.