TVS 2300 on built LS3 with stroker crank - Any ideas on how much boost we'll see?

#221

If you're running that much tension on the belt and it's still slipping it might be worth going to a tension with less tension and just spinning it slower. If you have to work the blower that hard that it's slipping the belt with 8 ribs and that much tension on it that just tells you that it's out of it's element. You could go with a 10 rib like the guy just did on performancetrucks.net, but either way your whole idea with the build of reliability is just going out with the truck. It's a good thing you didn't ship it out already. I'm suprised you haven't pulled that thing off there yet.

You're right, I'm glad it didn't get shipped yet..

At one point Brian was going to send out the 2nd blower to us with a cog drive, but they felt it wasn't perfected enough to have it installed on a vehicle that was getting shipped overseas. Bob

#222

That sounds like a plan. Build a custom setup so the blower has its own dedicated belt driving it. I am curious about your situation. Has no one else ever run a TVS2300 with the same pulley size you are running, or pushed the amount of air you are attempting to push? I would guess that the vehicle you have decided to maggie-charge is rather unique, but i cant believe that no-one has used a TVS2300 on a motor similar\same to what you are using it on, pushing similar\same boost with a similar\same pulleys. So why is it that you are experiencing such problems?? Why are you getting the amount of belt slippage you are seeing, and having to have the belt so tight it snaps water pumps in half?? Could it be that something is wrong with the blower itself, and that perhaps either the bearings are broken or something doesnt line up properly inside the blower, causing it to be extremely difficult to spin the blower?? This would explain why you are getting belt slippage no matter how tight you have the belt, no matter what you do.

Please keep us informed as too what happens, especially if you either solve the problems or abandon it. You and your shop's reputation proceeds you, and i don't think i am alone in being absolutely shocked that you hit a problem that has you stumped. I have seen some of the work you have done, building custom pieces and parts, modifying the body work and frame of cars to build one off setups, etc. Perhaps that is why something like "belt slip" stumping you has got my and other member's attention, as opposed to the 23000 other threads asking about belt slippage.

Best of luck to you Bob.

I am with you in that i am a bit surprised Bob hasnt said "Oh **** this, grab one of the big pro-chargers. What do you think, F1A or F1R for the hummer?"

Then again, i can understand looking at this as a personal challenge and being dedicated to solving the problem.

I say you try the best you can. First check out the blower, make sure it isnt fucked up. If it is ok, sit down with some of your fabricators and see if you can draw up an individual belt drive for the blower alone. If that wont work (wont fit, for example), try a cog drive. If that fails i say **** it, pull the maggie off and send it back. Then slap a big *** procharger on there and call it a day.

Please keep us informed as too what happens, especially if you either solve the problems or abandon it. You and your shop's reputation proceeds you, and i don't think i am alone in being absolutely shocked that you hit a problem that has you stumped. I have seen some of the work you have done, building custom pieces and parts, modifying the body work and frame of cars to build one off setups, etc. Perhaps that is why something like "belt slip" stumping you has got my and other member's attention, as opposed to the 23000 other threads asking about belt slippage.

Best of luck to you Bob.

I am with you in that i am a bit surprised Bob hasnt said "Oh **** this, grab one of the big pro-chargers. What do you think, F1A or F1R for the hummer?"

Then again, i can understand looking at this as a personal challenge and being dedicated to solving the problem.

I say you try the best you can. First check out the blower, make sure it isnt fucked up. If it is ok, sit down with some of your fabricators and see if you can draw up an individual belt drive for the blower alone. If that wont work (wont fit, for example), try a cog drive. If that fails i say **** it, pull the maggie off and send it back. Then slap a big *** procharger on there and call it a day.

Thanks for the comments, we appreciate it!

There are not very many 2300's out there, I believe we received the 3rd one. A lot more have been produced since we received this one, but I don't know of any that are really making a lot of boost. Perhaps there are some out there, but I haven't seen them posting about it. We have so much time and effort into this blower, that I would hate to have to swap it out now for a ProCharger. The ProCharger route was the was I initially wanted to go, but the business we built it for over in Saudi Arabia is a Magnacharger dealer, and they insisted on it having a Maggie. When it works it is doing quite well, propelling 7,000 lbs out of the hole like a rocket is amazing. If we can get a dedicated belt on the blower, and run the accessories seperate, I am sure it will work out. Bob

#225

12 Second Truck Club

iTrader: (25)

Join Date: Jan 2007

Posts: 1,104

Likes: 0

Received 0 Likes

on

0 Posts

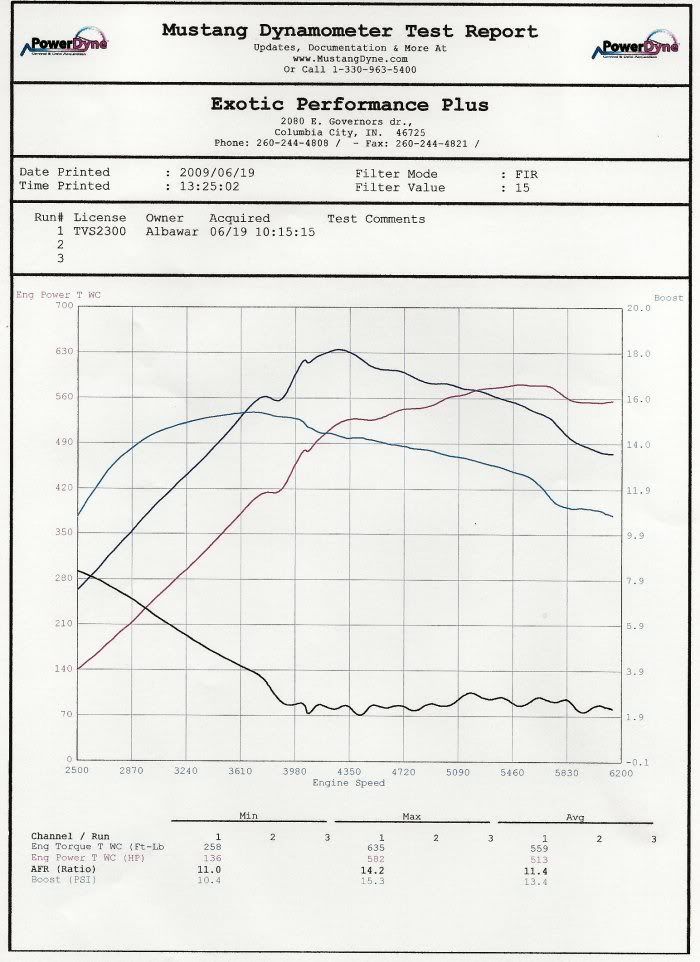

I Am sorry. Thought the 590 @ only 10 psi gave it away. 1st would be belt alignment is crucial. And 2nd at that boost level we got the best bang for the buck under those curcumstances.(

1st would be belt alignment is crucial. And 2nd at that boost level we got the best bang for the buck under those curcumstances.( Limits of the 10-rib rear

Limits of the 10-rib rear )

)

Is there more on tap? I shall soon see. I am changing the rear drive over to the cog and will start upping the boost on the front 8-rib drive to see what happens.

1st would be belt alignment is crucial. And 2nd at that boost level we got the best bang for the buck under those curcumstances.(

1st would be belt alignment is crucial. And 2nd at that boost level we got the best bang for the buck under those curcumstances.(

Is there more on tap? I shall soon see. I am changing the rear drive over to the cog and will start upping the boost on the front 8-rib drive to see what happens.

#229

12 Second Truck Club

iTrader: (25)

Join Date: Jan 2007

Posts: 1,104

Likes: 0

Received 0 Likes

on

0 Posts

Remember I was the first to install this type of drive system in a GMT-800 vehicle utilizing the 122hh, then the TVS. You are the first with the Hummer.

There are many similarities, and some not. working thru it will obtain the goals. But I would suggest looking at what you have already done. some of those things may or maynot be working for your combo.

I have thrown/ripped/scredded/and slipped so many belts, stuck on the side of the road, wrenching everything over and over. At this point I have hit the above listed #'s and continuing to increase them one step at a time.

My front drive setup required shimming/pulley adj in several different area's to obtain the longevity of its drive belt. Prior to that i could not go 2 mi with out some type of belt issue. Hense the statment "Drove to Vegas" still on the same belt.

once we arrived in vegas we believed to see the rear drive (10-rib)slipping only allowing 10 psi. Netting the #'s above.

Now I am switching over the rear drive to the cog similiar to your's

and will attempt larger boost/hp #'s.

we are not that different in over all combo's

How well is the front alignment on your set-up? where does the belt wrap on the water pump? more towards the front, or back. Is the drive side forward creating a tugging sensation?

#230

LS1Tech Sponsor

iTrader: (10)

10psi on a really nice 427 through a stalled 80e and large rear usually nets 800+ to the tires around here is all.

10psi on a stock 5.3l through 35's and a 14 bolt here was 550 to the tires with a 68mm t6 turbo. It went 12.0@110 on the 35's at 6k race weight. I just don't see where the TVS is supposed to shine at these levels.

Just like the 408's that can make 500 n/a making 550 with the wrong blower at 10psi or better.

10psi on a stock 5.3l through 35's and a 14 bolt here was 550 to the tires with a 68mm t6 turbo. It went 12.0@110 on the 35's at 6k race weight. I just don't see where the TVS is supposed to shine at these levels.

Just like the 408's that can make 500 n/a making 550 with the wrong blower at 10psi or better.

#231

#232

LS1Tech Sponsor

iTrader: (10)

I ran a 1900 and a 2300 both to 18800rpm and the boost on a built 427 was 6.1 and 9.0. This was at 3400' which is hard for the blower to make enough cfm to get the boost. I expect there is no way you can make 14 psi unless you have a tiny engine. I had a major failure on both blowers so be careful if you're pushing it.

I concur!

#233

Here is a "tiny" TVS 1900 on a 408... with slow 1.7-1.8 60's

http://www.undrprsr.com/images/stori...anderComp.html

http://www.undrprsr.com/images/stori...anderComp.html

#234

Its a work in progress thats all.

Remember I was the first to install this type of drive system in a GMT-800 vehicle utilizing the 122hh, then the TVS. You are the first with the Hummer.

There are many similarities, and some not. working thru it will obtain the goals. But I would suggest looking at what you have already done. some of those things may or maynot be working for your combo.

I have thrown/ripped/scredded/and slipped so many belts, stuck on the side of the road, wrenching everything over and over. At this point I have hit the above listed #'s and continuing to increase them one step at a time.

My front drive setup required shimming/pulley adj in several different area's to obtain the longevity of its drive belt. Prior to that i could not go 2 mi with out some type of belt issue. Hense the statment "Drove to Vegas" still on the same belt.

once we arrived in vegas we believed to see the rear drive (10-rib)slipping only allowing 10 psi. Netting the #'s above.

Now I am switching over the rear drive to the cog similiar to your's

and will attempt larger boost/hp #'s.

we are not that different in over all combo's

How well is the front alignment on your set-up? where does the belt wrap on the water pump? more towards the front, or back. Is the drive side forward creating a tugging sensation?

Remember I was the first to install this type of drive system in a GMT-800 vehicle utilizing the 122hh, then the TVS. You are the first with the Hummer.

There are many similarities, and some not. working thru it will obtain the goals. But I would suggest looking at what you have already done. some of those things may or maynot be working for your combo.

I have thrown/ripped/scredded/and slipped so many belts, stuck on the side of the road, wrenching everything over and over. At this point I have hit the above listed #'s and continuing to increase them one step at a time.

My front drive setup required shimming/pulley adj in several different area's to obtain the longevity of its drive belt. Prior to that i could not go 2 mi with out some type of belt issue. Hense the statment "Drove to Vegas" still on the same belt.

once we arrived in vegas we believed to see the rear drive (10-rib)slipping only allowing 10 psi. Netting the #'s above.

Now I am switching over the rear drive to the cog similiar to your's

and will attempt larger boost/hp #'s.

we are not that different in over all combo's

How well is the front alignment on your set-up? where does the belt wrap on the water pump? more towards the front, or back. Is the drive side forward creating a tugging sensation?

Cool. From your first post I thought you were making it sound like you have no problems at all in getting to where you are now.

We haven't shredded a belt yet until the water pump pulley comes off. The belt that we just had on it had 300 miles or so on it, and a lot of dyno time, and runs at a dragstrip. Had the water pump pulley not broken again, I'm sure we would still be on this belt. I'll have to see where the belt is riding on the pump, but I think our problem is because of the amount of belt tension we are using to keep slippage to a minimum. We have LeftCoast32 overdrive system on it, which uses an Innovators West overdrive harmonic balancer. Left Coast said they had to tig weld their water pump on an engine several years ago, we have ours tig welded 100% and it broke off above the weld. Bob

#235

I ran a 1900 and a 2300 both to 18800rpm and the boost on a built 427 was 6.1 and 9.0. This was at 3400' which is hard for the blower to make enough cfm to get the boost. I expect there is no way you can make 14 psi unless you have a tiny engine. I had a major failure on both blowers so be careful if you're pushing it.

#236

8" balancer and 2.8" pulley = 9 psi with no slip

what made 14 psi on your setup

#237

Here is a link to this truck and the entire build.

http://www.exoticperformanceplus.com...Car.php?car=56 Bob

#238

You are 100% correct.

Here is a link to this truck and the entire build.

http://www.exoticperformanceplus.com...Car.php?car=56 Bob

Here is a link to this truck and the entire build.

http://www.exoticperformanceplus.com...Car.php?car=56 Bob

#240

yeah, but the ZR1 blower doesnt have the best of airflow paths... Regardless, a 2300 is good for right around 850-900 crank hp. Not to many other 2.3L blowers that can do that.

it has a smaller 31.5 tall tire though.

it has a smaller 31.5 tall tire though.