UPDATED!!*DYNO NUMBERS* Comparison of Comp Turbo Billet 88mm CT6X-88 & GT91 Garrett!!

#402

Yes I believe so. Its just like all the other cheaper intercoolers on ebay. Weighed approximately 15lbs while my new one weighs about 30 pounds. IATs are much better too.

Took some work to make this guy fit

Took some work to make this guy fit

#404

So I just read this whole thread and I think I have a lot of info that will help you, although mine is a truck, and not a car

My setup consists of a 402 with L92 heads, 226/226 117 cam, and a log-style T4 BW s400sx3 turbo with an 80mm compressor, which also has the 87/81 turbine. 9.5 compression as well, and the stock intake. So pretty similar engines.

First lets talk about intercoolers, since that seems to be the topic we are currently on. I had a little 3" core ebay intercooler, probably the same one you had, 3" cold side piping, etc. I went to the dyno and wasnt seeing the numbers I expected so we hooked up a gauge to the compressor housing and compared to the manifold pressure and it went something like this:

Compressor - Manifold

13 - 9

19.5 - 12.5

24 - 16

And thats where we stopped for the day. I also gained 50hp by simply taking the filter off, FYI. You can read more about it here if you want: http://www.performancetrucks.net/for...4/#post4924189

So naturally I upgraded the intercooler to a 4" core CXR big *** intercooler and this is much larger and heavier than the ebay one, even though it is still a 3" in/out. Only ~$250 as well

Just by changing the intercooler gave me 2mph in the 1/8th (in a 5000lb truck mind you).

I installed a backpressure gauge around the same time, more for curiosity than anything else and here are some of my results, intercooler pressure drop data included:

RUN 1

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 10 10 10 10 10

Backpressure [psi] 18 18 18 20 22

Intake boost pressure [psi] 8 8 8 7.5 8

RUN 2

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 11 11.5 12 12 12

Backpressure [psi] 18 19 20 22 25

Intake boost pressure [psi] 9.5 8 8.5 8.5 8.5

RUN 3

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 13 13 13 14

Backpressure [psi] 0 19 22 25 27

Intake boost pressure [psi] 0 10.25 11 11 11

RUN 4

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 13 14 15 15 15

Backpressure [psi] 18 22 24 26 27

Intake boost pressure [psi] 12.75 13 13 13 13

RUN 5

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 16 16.5 17 17

Backpressure [psi] 0 25 27 30+ 30+

Intake boost pressure [psi] 16 15 15.5 15.5 15

Heres the thread if you want to read more about it: http://www.performancetrucks.net/for...-gauge-498800/

But notice backpressure starts going out of control pretty quickly, which I think is a product of how my kit is designed...it has the driver side feeding in to the back of the passenger side log, so all of the airflow of my engine is going through a 3" log to a T4 flange....I am currently having it rebuilt to a T6 and both sides converging at the flange so BP will hopefully be around the 1.5:1 range.

From the time I did the above test I tried out a 1.25 AR housing and gained another 2mph in the 1/8th. When I get my new hot pipes, I am going to use the same exact turbo, but with a 1.25AR T6 housing.

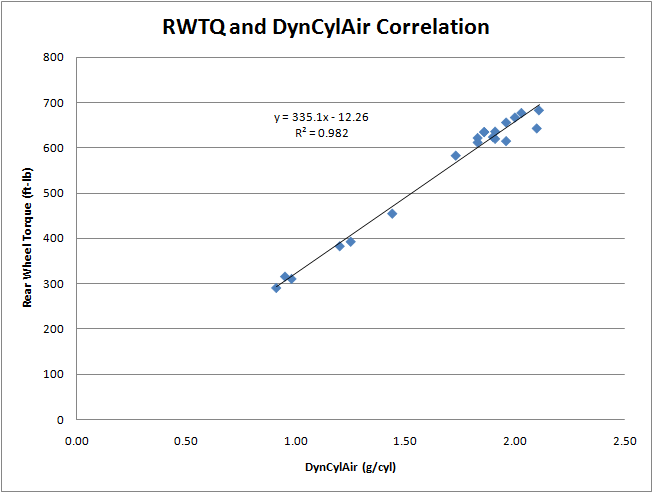

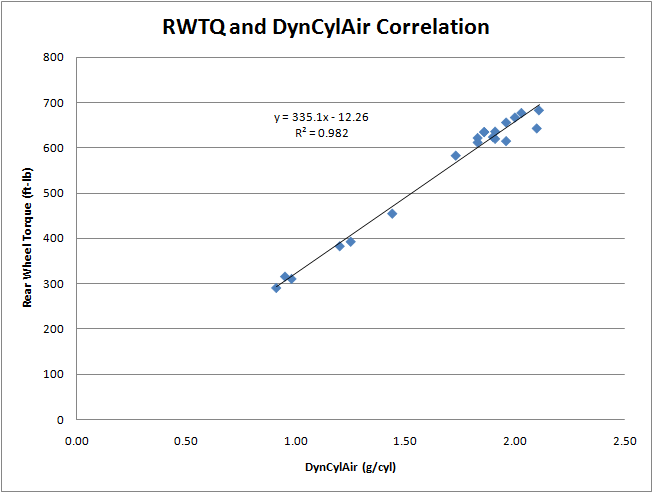

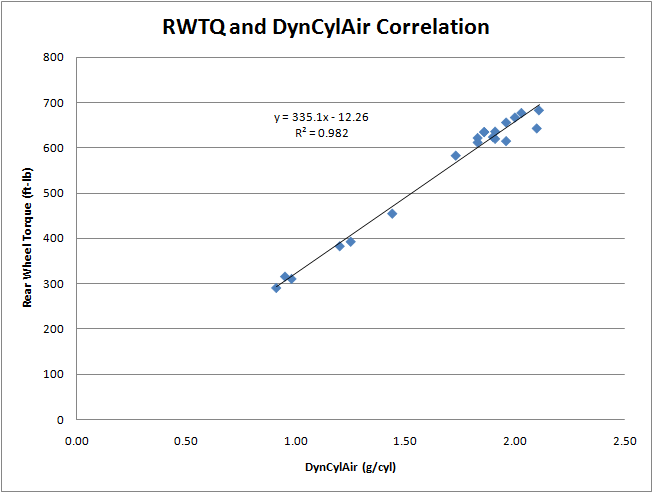

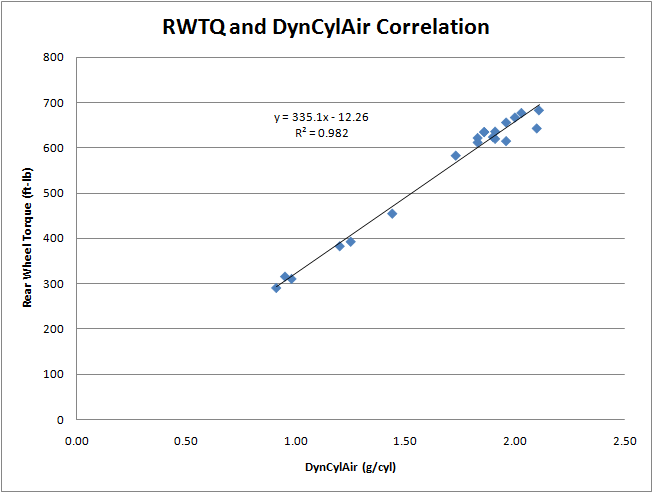

Going back to when I went to the dyno...I tune myself with hptuners and am pretty good at it. I had always heard of a relationship between the "dynamic cylinder air" pid and actual power, so I graphed it from my dyno run and hpt log...

I got a very good trend from this so I made a nice equation and pid for an "instant power" pid. Now someone is going to say since the conditions arent the same except for that day it wont be right. It is my understanding that the computer takes into account the IAT data when it calculates the dyncyl air, thereby making it correct. With this mind, I have had well over 1000hp at around 20psi...with a little T4 87mm turbine and 80mm compressor. I trap roughly 108mph in the 1/8th in a 5000lb truck, so that number is pretty accurate.

If its not obvious, I love tinkering and being analytical about it, so I would be happy to help you with anything. There is a lot of good info in this thread by a lot of smart people, but one thing keeps nagging at me....no one has pointed out that the turbine extracts roughly 80% of its power from heat, not pressure! When you are talking about high horsepower applications (I think 1000+ qualifies) you want as little BP as possible and it does nothing beneficial but amplify pumping losses of the engine!

As far as suggestions to you...get a better intercooler! The CRX ones are well priced and perform pretty damn good without spending 3x as much. Listen to the guys that have been doing this a long time...your current turbo is too much of a mismatch. Do you want 2000hp or quick spooling? Sorry you cant have both. If I can make 1000rwph through an unlocked 80e, and a 14b 9.5" rear with a little T4 80mm, there is no reason for you to be using a 100mm+ compressor. Go back to something with a better match in the 90mm compressor range with a bigass turbine and your drive ability and power will be way better.

My setup consists of a 402 with L92 heads, 226/226 117 cam, and a log-style T4 BW s400sx3 turbo with an 80mm compressor, which also has the 87/81 turbine. 9.5 compression as well, and the stock intake. So pretty similar engines.

First lets talk about intercoolers, since that seems to be the topic we are currently on. I had a little 3" core ebay intercooler, probably the same one you had, 3" cold side piping, etc. I went to the dyno and wasnt seeing the numbers I expected so we hooked up a gauge to the compressor housing and compared to the manifold pressure and it went something like this:

Compressor - Manifold

13 - 9

19.5 - 12.5

24 - 16

And thats where we stopped for the day. I also gained 50hp by simply taking the filter off, FYI. You can read more about it here if you want: http://www.performancetrucks.net/for...4/#post4924189

So naturally I upgraded the intercooler to a 4" core CXR big *** intercooler and this is much larger and heavier than the ebay one, even though it is still a 3" in/out. Only ~$250 as well

Just by changing the intercooler gave me 2mph in the 1/8th (in a 5000lb truck mind you).

I installed a backpressure gauge around the same time, more for curiosity than anything else and here are some of my results, intercooler pressure drop data included:

RUN 1

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 10 10 10 10 10

Backpressure [psi] 18 18 18 20 22

Intake boost pressure [psi] 8 8 8 7.5 8

RUN 2

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 11 11.5 12 12 12

Backpressure [psi] 18 19 20 22 25

Intake boost pressure [psi] 9.5 8 8.5 8.5 8.5

RUN 3

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 13 13 13 14

Backpressure [psi] 0 19 22 25 27

Intake boost pressure [psi] 0 10.25 11 11 11

RUN 4

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 13 14 15 15 15

Backpressure [psi] 18 22 24 26 27

Intake boost pressure [psi] 12.75 13 13 13 13

RUN 5

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 16 16.5 17 17

Backpressure [psi] 0 25 27 30+ 30+

Intake boost pressure [psi] 16 15 15.5 15.5 15

Heres the thread if you want to read more about it: http://www.performancetrucks.net/for...-gauge-498800/

But notice backpressure starts going out of control pretty quickly, which I think is a product of how my kit is designed...it has the driver side feeding in to the back of the passenger side log, so all of the airflow of my engine is going through a 3" log to a T4 flange....I am currently having it rebuilt to a T6 and both sides converging at the flange so BP will hopefully be around the 1.5:1 range.

From the time I did the above test I tried out a 1.25 AR housing and gained another 2mph in the 1/8th. When I get my new hot pipes, I am going to use the same exact turbo, but with a 1.25AR T6 housing.

Going back to when I went to the dyno...I tune myself with hptuners and am pretty good at it. I had always heard of a relationship between the "dynamic cylinder air" pid and actual power, so I graphed it from my dyno run and hpt log...

I got a very good trend from this so I made a nice equation and pid for an "instant power" pid. Now someone is going to say since the conditions arent the same except for that day it wont be right. It is my understanding that the computer takes into account the IAT data when it calculates the dyncyl air, thereby making it correct. With this mind, I have had well over 1000hp at around 20psi...with a little T4 87mm turbine and 80mm compressor. I trap roughly 108mph in the 1/8th in a 5000lb truck, so that number is pretty accurate.

If its not obvious, I love tinkering and being analytical about it, so I would be happy to help you with anything. There is a lot of good info in this thread by a lot of smart people, but one thing keeps nagging at me....no one has pointed out that the turbine extracts roughly 80% of its power from heat, not pressure! When you are talking about high horsepower applications (I think 1000+ qualifies) you want as little BP as possible and it does nothing beneficial but amplify pumping losses of the engine!

As far as suggestions to you...get a better intercooler! The CRX ones are well priced and perform pretty damn good without spending 3x as much. Listen to the guys that have been doing this a long time...your current turbo is too much of a mismatch. Do you want 2000hp or quick spooling? Sorry you cant have both. If I can make 1000rwph through an unlocked 80e, and a 14b 9.5" rear with a little T4 80mm, there is no reason for you to be using a 100mm+ compressor. Go back to something with a better match in the 90mm compressor range with a bigass turbine and your drive ability and power will be way better.

#405

Getting ready for twin & took a really good look at my ebay intercooler. By my hillbilly math it has 16 passages that are 1/4" by 4" which equals 16" of opening right? Of course there are the fins that fill the holes. I can see through to the other side easily.

I am considering re-using it for the twin build by just installing a y into the cooler.

Here are some pics. You can see my flash light from the other side on one of the pics. It is a 24X12 core that I have had for years. IAT's always good, ran mid 9's in good air. It is a very heavy unit.

I am considering re-using it for the twin build by just installing a y into the cooler.

Here are some pics. You can see my flash light from the other side on one of the pics. It is a 24X12 core that I have had for years. IAT's always good, ran mid 9's in good air. It is a very heavy unit.

#406

Thread Starter

Joined: Jun 2006

Posts: 1,460

Likes: 7

From: Orange County, CA

So I just read this whole thread and I think I have a lot of info that will help you, although mine is a truck, and not a car

My setup consists of a 402 with L92 heads, 226/226 117 cam, and a log-style T4 BW s400sx3 turbo with an 80mm compressor, which also has the 87/81 turbine. 9.5 compression as well, and the stock intake. So pretty similar engines.

First lets talk about intercoolers, since that seems to be the topic we are currently on. I had a little 3" core ebay intercooler, probably the same one you had, 3" cold side piping, etc. I went to the dyno and wasnt seeing the numbers I expected so we hooked up a gauge to the compressor housing and compared to the manifold pressure and it went something like this:

Compressor - Manifold

13 - 9

19.5 - 12.5

24 - 16

And thats where we stopped for the day. I also gained 50hp by simply taking the filter off, FYI. You can read more about it here if you want: http://www.performancetrucks.net/for...4/#post4924189

So naturally I upgraded the intercooler to a 4" core CXR big *** intercooler and this is much larger and heavier than the ebay one, even though it is still a 3" in/out. Only ~$250 as well

Just by changing the intercooler gave me 2mph in the 1/8th (in a 5000lb truck mind you).

I installed a backpressure gauge around the same time, more for curiosity than anything else and here are some of my results, intercooler pressure drop data included:

RUN 1

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 10 10 10 10 10

Backpressure [psi] 18 18 18 20 22

Intake boost pressure [psi] 8 8 8 7.5 8

RUN 2

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 11 11.5 12 12 12

Backpressure [psi] 18 19 20 22 25

Intake boost pressure [psi] 9.5 8 8.5 8.5 8.5

RUN 3

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 13 13 13 14

Backpressure [psi] 0 19 22 25 27

Intake boost pressure [psi] 0 10.25 11 11 11

RUN 4

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 13 14 15 15 15

Backpressure [psi] 18 22 24 26 27

Intake boost pressure [psi] 12.75 13 13 13 13

RUN 5

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 16 16.5 17 17

Backpressure [psi] 0 25 27 30+ 30+

Intake boost pressure [psi] 16 15 15.5 15.5 15

Heres the thread if you want to read more about it: http://www.performancetrucks.net/for...-gauge-498800/

But notice backpressure starts going out of control pretty quickly, which I think is a product of how my kit is designed...it has the driver side feeding in to the back of the passenger side log, so all of the airflow of my engine is going through a 3" log to a T4 flange....I am currently having it rebuilt to a T6 and both sides converging at the flange so BP will hopefully be around the 1.5:1 range.

From the time I did the above test I tried out a 1.25 AR housing and gained another 2mph in the 1/8th. When I get my new hot pipes, I am going to use the same exact turbo, but with a 1.25AR T6 housing.

Going back to when I went to the dyno...I tune myself with hptuners and am pretty good at it. I had always heard of a relationship between the "dynamic cylinder air" pid and actual power, so I graphed it from my dyno run and hpt log...

I got a very good trend from this so I made a nice equation and pid for an "instant power" pid. Now someone is going to say since the conditions arent the same except for that day it wont be right. It is my understanding that the computer takes into account the IAT data when it calculates the dyncyl air, thereby making it correct. With this mind, I have had well over 1000hp at around 20psi...with a little T4 87mm turbine and 80mm compressor. I trap roughly 108mph in the 1/8th in a 5000lb truck, so that number is pretty accurate.

If its not obvious, I love tinkering and being analytical about it, so I would be happy to help you with anything. There is a lot of good info in this thread by a lot of smart people, but one thing keeps nagging at me....no one has pointed out that the turbine extracts roughly 80% of its power from heat, not pressure! When you are talking about high horsepower applications (I think 1000+ qualifies) you want as little BP as possible and it does nothing beneficial but amplify pumping losses of the engine!

As far as suggestions to you...get a better intercooler! The CRX ones are well priced and perform pretty damn good without spending 3x as much. Listen to the guys that have been doing this a long time...your current turbo is too much of a mismatch. Do you want 2000hp or quick spooling? Sorry you cant have both. If I can make 1000rwph through an unlocked 80e, and a 14b 9.5" rear with a little T4 80mm, there is no reason for you to be using a 100mm+ compressor. Go back to something with a better match in the 90mm compressor range with a bigass turbine and your drive ability and power will be way better.

My setup consists of a 402 with L92 heads, 226/226 117 cam, and a log-style T4 BW s400sx3 turbo with an 80mm compressor, which also has the 87/81 turbine. 9.5 compression as well, and the stock intake. So pretty similar engines.

First lets talk about intercoolers, since that seems to be the topic we are currently on. I had a little 3" core ebay intercooler, probably the same one you had, 3" cold side piping, etc. I went to the dyno and wasnt seeing the numbers I expected so we hooked up a gauge to the compressor housing and compared to the manifold pressure and it went something like this:

Compressor - Manifold

13 - 9

19.5 - 12.5

24 - 16

And thats where we stopped for the day. I also gained 50hp by simply taking the filter off, FYI. You can read more about it here if you want: http://www.performancetrucks.net/for...4/#post4924189

So naturally I upgraded the intercooler to a 4" core CXR big *** intercooler and this is much larger and heavier than the ebay one, even though it is still a 3" in/out. Only ~$250 as well

Just by changing the intercooler gave me 2mph in the 1/8th (in a 5000lb truck mind you).

I installed a backpressure gauge around the same time, more for curiosity than anything else and here are some of my results, intercooler pressure drop data included:

RUN 1

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 10 10 10 10 10

Backpressure [psi] 18 18 18 20 22

Intake boost pressure [psi] 8 8 8 7.5 8

RUN 2

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 11 11.5 12 12 12

Backpressure [psi] 18 19 20 22 25

Intake boost pressure [psi] 9.5 8 8.5 8.5 8.5

RUN 3

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 13 13 13 14

Backpressure [psi] 0 19 22 25 27

Intake boost pressure [psi] 0 10.25 11 11 11

RUN 4

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 13 14 15 15 15

Backpressure [psi] 18 22 24 26 27

Intake boost pressure [psi] 12.75 13 13 13 13

RUN 5

RPM 5200 5500 5800 6000 6200

Compressor Pressure [psi] 0 16 16.5 17 17

Backpressure [psi] 0 25 27 30+ 30+

Intake boost pressure [psi] 16 15 15.5 15.5 15

Heres the thread if you want to read more about it: http://www.performancetrucks.net/for...-gauge-498800/

But notice backpressure starts going out of control pretty quickly, which I think is a product of how my kit is designed...it has the driver side feeding in to the back of the passenger side log, so all of the airflow of my engine is going through a 3" log to a T4 flange....I am currently having it rebuilt to a T6 and both sides converging at the flange so BP will hopefully be around the 1.5:1 range.

From the time I did the above test I tried out a 1.25 AR housing and gained another 2mph in the 1/8th. When I get my new hot pipes, I am going to use the same exact turbo, but with a 1.25AR T6 housing.

Going back to when I went to the dyno...I tune myself with hptuners and am pretty good at it. I had always heard of a relationship between the "dynamic cylinder air" pid and actual power, so I graphed it from my dyno run and hpt log...

I got a very good trend from this so I made a nice equation and pid for an "instant power" pid. Now someone is going to say since the conditions arent the same except for that day it wont be right. It is my understanding that the computer takes into account the IAT data when it calculates the dyncyl air, thereby making it correct. With this mind, I have had well over 1000hp at around 20psi...with a little T4 87mm turbine and 80mm compressor. I trap roughly 108mph in the 1/8th in a 5000lb truck, so that number is pretty accurate.

If its not obvious, I love tinkering and being analytical about it, so I would be happy to help you with anything. There is a lot of good info in this thread by a lot of smart people, but one thing keeps nagging at me....no one has pointed out that the turbine extracts roughly 80% of its power from heat, not pressure! When you are talking about high horsepower applications (I think 1000+ qualifies) you want as little BP as possible and it does nothing beneficial but amplify pumping losses of the engine!

As far as suggestions to you...get a better intercooler! The CRX ones are well priced and perform pretty damn good without spending 3x as much. Listen to the guys that have been doing this a long time...your current turbo is too much of a mismatch. Do you want 2000hp or quick spooling? Sorry you cant have both. If I can make 1000rwph through an unlocked 80e, and a 14b 9.5" rear with a little T4 80mm, there is no reason for you to be using a 100mm+ compressor. Go back to something with a better match in the 90mm compressor range with a bigass turbine and your drive ability and power will be way better.

great data! Im out of town right now and havent had much time to really go over it thoroughly, but thanks for taking the time to give me all that info!

#407

#409

Most of the energy imparted to the turbine is from airflow, then perhaps heat and pressure.

Pressure is a by-product, and an unwanted one really. Ideally you'd have the turbine operate at zero pressure, with unrestricted flow out the exhaust.

But obviously heat energy can be used to help that task, but it is not the main source of energy to drive the turbine.

#411

I would disagree with that statement.

Most of the energy imparted to the turbine is from airflow, then perhaps heat and pressure.

Pressure is a by-product, and an unwanted one really. Ideally you'd have the turbine operate at zero pressure, with unrestricted flow out the exhaust.

But obviously heat energy can be used to help that task, but it is not the main source of energy to drive the turbine.

Most of the energy imparted to the turbine is from airflow, then perhaps heat and pressure.

Pressure is a by-product, and an unwanted one really. Ideally you'd have the turbine operate at zero pressure, with unrestricted flow out the exhaust.

But obviously heat energy can be used to help that task, but it is not the main source of energy to drive the turbine.

I went back and double checked my sources after this and even emailed an engineer at honeywell, and here was his response:

The super simple answer is: the job of a turbine is to extract energy. Heat = energy.

So this link shows a basic gas turbine with the turbine equation:

http://www.grc.nasa.gov/WWW/k-12/airplane/powtrbth.html

Looking at the equation, turbine inlet temperature is a major variable as is Pressure Ratio. However, Pressure Ratio is to the power of (gamma-1)/gamma, which is less than 1, therefore the change in turbine power is less sensative to changes in PR than temperature. Also, pressure ratio is a function of temperature itself, so you can take pressure ratio out of the equation completely. That leaves only temperature. So temperature/heat is the main driver either way you look at it.

So this link shows a basic gas turbine with the turbine equation:

http://www.grc.nasa.gov/WWW/k-12/airplane/powtrbth.html

Looking at the equation, turbine inlet temperature is a major variable as is Pressure Ratio. However, Pressure Ratio is to the power of (gamma-1)/gamma, which is less than 1, therefore the change in turbine power is less sensative to changes in PR than temperature. Also, pressure ratio is a function of temperature itself, so you can take pressure ratio out of the equation completely. That leaves only temperature. So temperature/heat is the main driver either way you look at it.

#412

Again, I disagree.

If you had a heat source of say 2000degF and applied it to the turbine. It would just cook.

The turbine wheel is designed to be rotated by airflow, not heat.

An internal combustion engine with a turbo isnt the same as a gas turbine. Although even a gas turbine would be pretty useless without any airflow.

I'm certainly no expert, but I'd say the heat statement is taken out of context for a turbo/engine scenario.

If you were to spin an engine over at 5000rpm with no combustion taking place and hence very little heat produced, the turbine would still spin and probably produce some boost.

If you had a heat source of say 2000degF and applied it to the turbine. It would just cook.

The turbine wheel is designed to be rotated by airflow, not heat.

An internal combustion engine with a turbo isnt the same as a gas turbine. Although even a gas turbine would be pretty useless without any airflow.

I'm certainly no expert, but I'd say the heat statement is taken out of context for a turbo/engine scenario.

If you were to spin an engine over at 5000rpm with no combustion taking place and hence very little heat produced, the turbine would still spin and probably produce some boost.

#413

I think the statement heat drives the turbine not pressure is incorrect. It should be heat creates pressure to drive the turbine. Heat is a major factor of creating pressure to drive the turbine.

Yes the turbines job is to extract energy that is created from heat and gas flow, the heat creating more gas flow.

Yes the turbines job is to extract energy that is created from heat and gas flow, the heat creating more gas flow.

#414

Following up on my ascertion, if 80% of the power is from heat, then the other 20% is most likely from kinetic energy, such as air blowing over the blades in a non-combusting engine. So yes the turbo will still spin without heat. A turbocharger is exactly a gas turbine, but with an intermittent flame instead of a constant one. At high rpm you could make the argument the time delay between exhaust pulses is so small it may as well be modeled as a constant flame application. You dont have to believe me, but there it is.

#415

Following up on my ascertion, if 80% of the power is from heat, then the other 20% is most likely from kinetic energy, such as air blowing over the blades in a non-combusting engine. So yes the turbo will still spin without heat. A turbocharger is exactly a gas turbine, but with an intermittent flame instead of a constant one. At high rpm you could make the argument the time delay between exhaust pulses is so small it may as well be modeled as a constant flame application. You dont have to believe me, but there it is.

#416

Ah, I think I see the confusion. When I refer to pressure I am really talking about the backpressure ratio, which is of course the ratio of pressure before the turbine divided by the output pressure of the compressor. With that in mind, yes there is always a positive pressure towards the turbine and hence gas flow. My point is, increasing this ratio (and therefor pre-turbine pressure) does absolutely nothing beneficial for the system, but increasing the "heat" (better described by total enthalpy, actually) will provide more useable power to the turbo.

#417

Ah, I think I see the confusion. When I refer to pressure I am really talking about the backpressure ratio, which is of course the ratio of pressure before the turbine divided by the output pressure of the compressor. With that in mind, yes there is always a positive pressure towards the turbine and hence gas flow. My point is, increasing this ratio (and therefor pre-turbine pressure) does absolutely nothing beneficial for the system, but increasing the "heat" (better described by total enthalpy, actually) will provide more useable power to the turbo.