UD Powerbond installation help. pics inside

#1

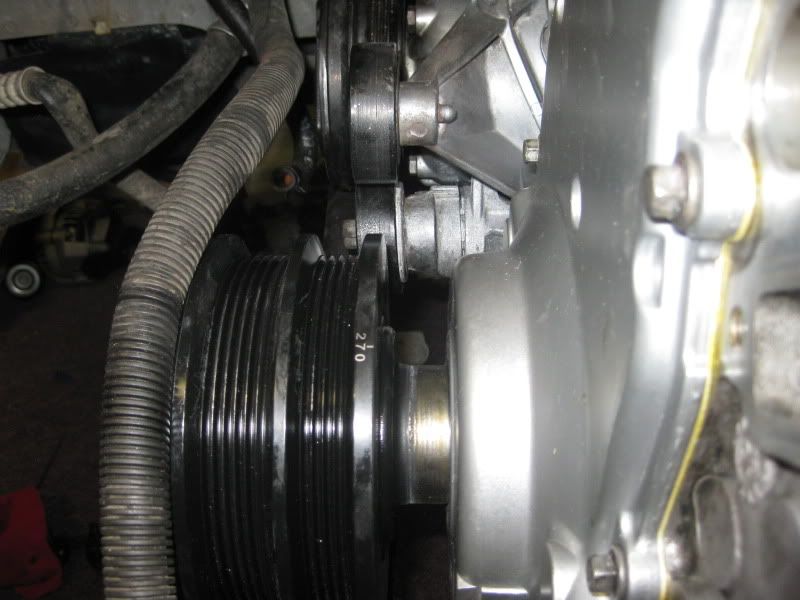

I purcahsed a Powerbond UD pulley from Scoggin Dickey, i took the old one off, now i am trying to get the new one on there. From the looks of the alignment with the a/c pulleys, it needs to go in about half an inch more. My problem is it wont go in any further.

Rear wheels are on the ground, I have a buddy stepping on the brakes, I am using a breaker bar with another 3 foot pipe for leverage and it still wont seem to tighten any more...I am using the crank pulley bolt they supplied with this kit. Should i tow this thing to the mechanic shop and have them use a impact gun? I just bought one from home depot but it doesnt seem like my compressor is strong enough (90 PSI). Has anyone else encountered this problem while installing the Powerbond UD pulley? Please help!

Rear wheels are on the ground, I have a buddy stepping on the brakes, I am using a breaker bar with another 3 foot pipe for leverage and it still wont seem to tighten any more...I am using the crank pulley bolt they supplied with this kit. Should i tow this thing to the mechanic shop and have them use a impact gun? I just bought one from home depot but it doesnt seem like my compressor is strong enough (90 PSI). Has anyone else encountered this problem while installing the Powerbond UD pulley? Please help!

#3

TECH Resident

iTrader: (7)

Join Date: Apr 2007

Location: STL, Mo

Posts: 954

Likes: 0

Received 0 Likes

on

0 Posts

You need to torch that bad boy. Take it off the crank and buy yourself a propane torch. We had to torch my friends (SLP) to install it. You also want to use your old bolt to install it first.

#4

I really dont think its going in any further, we had 2 guys pull on the breaker bar with an extension pipe and it still wont move....

There isnt a certain way you place on the crank hub right? I Just placed it on the crank hub and bolt it down to what you see in the pics... and What do you mean by torch it?

#5

10 Second Club

iTrader: (9)

So since its already half way in.. should i remove the black bolt supplied with the kit, bolt it down with the stock.. after it sets in, remove it, then bolt it down with the black on?

I really dont think its going in any further, we had 2 guys pull on the breaker bar with an extension pipe and it still wont move....

There isnt a certain way you place on the crank hub right? I Just placed it on the crank hub and bolt it down to what you see in the pics... and What do you mean by torch it?

I really dont think its going in any further, we had 2 guys pull on the breaker bar with an extension pipe and it still wont move....

There isnt a certain way you place on the crank hub right? I Just placed it on the crank hub and bolt it down to what you see in the pics... and What do you mean by torch it?

What he means is, take the pully back off, get you a portable blow torch and heat the sucker up, dont go for red and glowing, but go for getting some smoke out of it. Mainly just heat up the area around the bolt hole. then use your OLD bolt and use that to put it on and align it up, then once its in the correct place, use your new bolt to Torque it down to specs.

Those bolts are a one time use thing, you may need to get yourself a new bolt since you have torqued that one down so much.

#6

Ive had my asp off a couple times, I've found putting it in the oven for about 15 minutes at low temps works wonders. I just run it out and it sides halfway on the crank and it pulls on easily afterwords.

Trending Topics

#8

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

Its good that you stopped when you realized it wasnt going. I personally wouldnt use a bolt to pull the pulley on. Its not the right way to do it. However, which such a tight fit there are a few things you can do to make it start a little easier. First, run some light sandpaper around the crank snout and the inside of the pulley's hub. Wipe them down with alcohol to remove any debris, then coat them with engine oil. As you are first starting it, its gonna want to start crooked. So be patient and try as many times as it takes. Once its barely on, if it looks crooked, tap the opposite site lightly to see if it will square up.

#10

What he means is, take the pully back off, get you a portable blow torch and heat the sucker up, dont go for red and glowing, but go for getting some smoke out of it. Mainly just heat up the area around the bolt hole. then use your OLD bolt and use that to put it on and align it up, then once its in the correct place, use your new bolt to Torque it down to specs.

Those bolts are a one time use thing, you may need to get yourself a new bolt since you have torqued that one down so much.

Those bolts are a one time use thing, you may need to get yourself a new bolt since you have torqued that one down so much.

Its good that you stopped when you realized it wasnt going. I personally wouldnt use a bolt to pull the pulley on. Its not the right way to do it. However, which such a tight fit there are a few things you can do to make it start a little easier. First, run some light sandpaper around the crank snout and the inside of the pulley's hub. Wipe them down with alcohol to remove any debris, then coat them with engine oil. As you are first starting it, its gonna want to start crooked. So be patient and try as many times as it takes. Once its barely on, if it looks crooked, tap the opposite site lightly to see if it will square up.

Well, i did give it a few attempts to get that thing on as far as with the breaker bar, i wasnt beating it with a hammer or anything.

The crank hub is free of any debris, shinny and smooth. i DIDNT coat the hub with engine oil, its not crooked either.

Thanks for the fast reponses from everyone BTW!

Correct me if im wrong,

-Clean and wipe down any debris from the crank snount.

-Coat the snout with engine oil

-Baked the pulley for 15mins at ____ degrees?

-Take a old GM crank bolt and bolt it in place

-Once in place remove the old crank bolt

-Torque down the crank bolt to torque specs and call it a day

#13

first time I put a UD pulley on was a total bitch, used the oven method. Second time I put the pulley in the oven at 300* for 45 minutes THEN took a MAP torch to that bitch, went on so easy it was scarey. Just my 2 cents.

#14

sounds good, i will do this tomorrow

From what it seems like, most people are heating these things up and the greasing down the snout for the install.. thanks for the inpuit! ill give this a shot and keep you guys posted.

#15

I finally got the crank bolt out and saw this!?

As you can see in the above pictures, the pulley was on there flat, not crooked. Scoggin Dickey, I sent you a PM regarding the issue I am having with this set up. I really hope my crank shaft is not damage because the last thing I want to do is spend a grand for a crankshaft, atleast not right now. What do you guys suggest? re-threading the crankshaft?

As you can see in the above pictures, the pulley was on there flat, not crooked. Scoggin Dickey, I sent you a PM regarding the issue I am having with this set up. I really hope my crank shaft is not damage because the last thing I want to do is spend a grand for a crankshaft, atleast not right now. What do you guys suggest? re-threading the crankshaft?

#16

TECH Senior Member

iTrader: (8)

Go to the second post in this thread (vette nuts) and that is the only way I would ever pull a pulley on.https://ls1tech.com/forums/generatio...y-install.html You can engage all the threads in the crank and really not have to worry about stripping it out this way. I am not sure a tap and die will fix your situation but I think it is worth a try. Also use the arp bolt as it is longer. If it will torque to 240ft. lbs I think you are OK..... Oh and the oven method I have seen work at 200* for 30 minutes.

#17

Go to the second post in this thread (vette nuts) and that is the only way I would ever pull a pulley on.https://ls1tech.com/forums/generatio...y-install.html You can engage all the threads in the crank and really not have to worry about stripping it out this way. I am not sure a tap and die will fix your situation but I think it is worth a try. Also use the arp bolt as it is longer. If it will torque to 240ft. lbs I think you are OK..... Oh and the oven method I have seen work at 200* for 30 minutes.

#19

yeah, tell me about it. I dont know how the hell i missed this.. Just got back from home depot and all they had were standard.. I'll try a hardware store tmro morning. This damn bolt is a f*kin hassle without the right tools and knowledge. Its my first one so i had to learn some how. Im hoping I can re thread the first couple of threads on the crank (IF i have to that is...) and get it on there the rightI way!

Last edited by johnzss; 12-28-2009 at 11:06 PM.

#20

alright.. saved the crank shaft.. turns out it was the first couple threads that was torn up but I managed to get a tap set and rethread em. The pulley is now seated, A/C belt in tack.

Now what do you guys suggest? The black ARP style bolt supplied was the same length as the stock GM bolt. I have a brand new GM bolt, should i just secure the pulley down with that? or is there something else i can use? A lot of members recommened the longer bolt but since i just had the ARP style bolt, i measured it and its NOT longer. Connfused here...

Now what do you guys suggest? The black ARP style bolt supplied was the same length as the stock GM bolt. I have a brand new GM bolt, should i just secure the pulley down with that? or is there something else i can use? A lot of members recommened the longer bolt but since i just had the ARP style bolt, i measured it and its NOT longer. Connfused here...