Cam degreeing...what am I doing wrong?!

#1

Alright, so I've got the Comp degreeing kit and I watched their video about the whole process. I've got an adjustable cam gear that uses the little "rings" that go in the dowel hole in the gear which is what adjusts the timing. A picture of these things is below. The problem is I've tried 4 different rings and each time I either get 112.5 deg ICL or 105 deg ICL. My goal is 109 with this cam so what am I doing wrong? I thought each ring is supposed to give a different ICL

Edit: a couple more details: cam is a 113+4 and I found TDC using piston #4 and also ICL using the intake lifter on #4 cylinder but I didn't think that mattered as long as you're using the same piston each time.

Edit: a couple more details: cam is a 113+4 and I found TDC using piston #4 and also ICL using the intake lifter on #4 cylinder but I didn't think that mattered as long as you're using the same piston each time.

Last edited by Red99TA; 06-23-2009 at 09:31 PM.

#2

Staging Lane

iTrader: (9)

Join Date: Feb 2009

Location: illinois

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

i've only used #1. are you using the piston stop to find top dead center?you go both and forth turningthe motor by hand against the stop, take your readings divide by 2 and set the pointer.

#3

No, I'm using the dial indicator on the piston to find TDC and set the pointer to zero. Once it's set I rotate to .050" of piston travel on the way up and on the way down and ensure the wheel is showing the same reading (one will be like -11 deg and the other +11 deg which tells me 0 is TDC). I'm going to try my stock cam gear tonight just to see where it's at dot to dot and then move all my stuff to piston #1 to see if that makes any difference.

#4

TECH Senior Member

iTrader: (4)

I would go a little deeper on the piston and check, say 0.300" before and after. Problem with 0.050" is you are near the tangent point so it can build in some inaccuracy whereas farther down the cylinder this inaccuracy is greatly reduced. This will provide a quick check to make sure your initial TDC is correct.

Second, check the valve at 0.050" after opening and 0.050" before closing against the values on the cam card. This will double check the ICL method. I have never used #4 either, always #1.

Second, check the valve at 0.050" after opening and 0.050" before closing against the values on the cam card. This will double check the ICL method. I have never used #4 either, always #1.

#5

Staging Lane

iTrader: (9)

Join Date: Feb 2009

Location: illinois

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

you should have a 0 degree bushing so you wouldn't have to change the gear.i have the comp instructions,it is important that the dial indicator is setup to be parallel to the lifter.rotate the engine in the normal direction until you reach maximum lift, the dial indicator will change direction at the point of maximum lift. at this point set the dial to zero. back the engine up until the indicator reads .100"turn the engine back in the normal direction until the dial reads .050" before maximum lift. record the degree wheel reading.now continue to rotate the engine in the normal direction until the dial goes past zero to .050" on the closing side of maximum lift. record this reading.add the 2 numbers together and divide by 2. that number is your intake center line

#6

Thanks guys. I put what I thought was the 0 deg bushing in there and thats how I got my first 105 deg ICL (got 105 ICL w/ another bushing too). I'll move my stuff over to piston #1, try the stock gear just for ***** and giggles (I'm getting pretty fast at swapping the gear/chain with a new bushing anyways) and then I'll also make sure I'm getting to TDC like you recommended taking the piston down 0.100" before coming up. Also I was doing just what you said ccrider about finding max lift, going 0.050" back and 0.050" past max lift and then dividing the readings by 2.

#7

Staging Lane

iTrader: (9)

Join Date: Feb 2009

Location: illinois

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

wish you were closer, i feel your pain, i had to keep at it to figure out what i was doing. maybe your machine shop could help you. i talked to mine and he let me watch him dial one in to get feel for it.

Trending Topics

#8

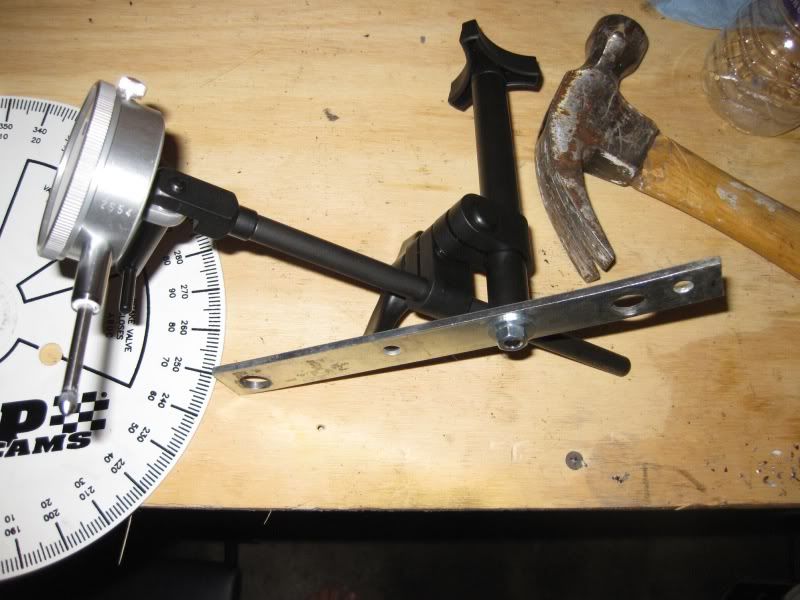

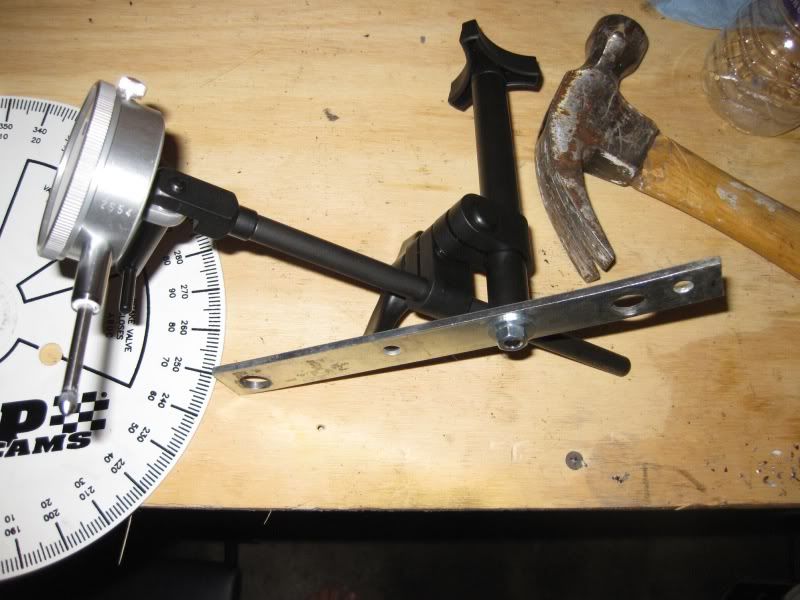

Well I finally got it after probably a combined total of 4 hrs screwing with the timing. I put in the stock cam gear dot to dot and found it to be at 112 (needs to be 109). Put the adjustable cam gear back on with one of my comp bushings and had my dial indicator on piston #1 and it moved to 105 deg ICL. Pulled the gear off and rotated the bushing upside down and it came out to 109.5 - CLOSE ENOUGH!  To check it I verified I still had TDC set correctly and measured again and was still at 109.5. Below are pics of the setup. I had to make an adapter plate to get the comp base to mount to my block since it wouldn't thread into any of the holes in the block. Also didn't have a dial indicator extension so I had to mount the dial indicator as close to the lifter as possible which would only make contact with about the last 0.200" of lift but all you really need is max lift +/- about 0.100" lift so it worked out.

To check it I verified I still had TDC set correctly and measured again and was still at 109.5. Below are pics of the setup. I had to make an adapter plate to get the comp base to mount to my block since it wouldn't thread into any of the holes in the block. Also didn't have a dial indicator extension so I had to mount the dial indicator as close to the lifter as possible which would only make contact with about the last 0.200" of lift but all you really need is max lift +/- about 0.100" lift so it worked out.

To check it I verified I still had TDC set correctly and measured again and was still at 109.5. Below are pics of the setup. I had to make an adapter plate to get the comp base to mount to my block since it wouldn't thread into any of the holes in the block. Also didn't have a dial indicator extension so I had to mount the dial indicator as close to the lifter as possible which would only make contact with about the last 0.200" of lift but all you really need is max lift +/- about 0.100" lift so it worked out.

To check it I verified I still had TDC set correctly and measured again and was still at 109.5. Below are pics of the setup. I had to make an adapter plate to get the comp base to mount to my block since it wouldn't thread into any of the holes in the block. Also didn't have a dial indicator extension so I had to mount the dial indicator as close to the lifter as possible which would only make contact with about the last 0.200" of lift but all you really need is max lift +/- about 0.100" lift so it worked out.

Last edited by Red99TA; 06-24-2009 at 06:10 PM.