Pro-Comp Head Studs sold on Ebay

#121

TECH Fanatic

iTrader: (35)

I sent a message to an eBay seller of the ProComp studs & here is the reply:

Thank you for your inquiry on our Pro Comp LS head studs. To answer your question, if you are unsure on what to torque these to, I would suggest contacting Pro Comp direct, and speaking with a tech. They can be reached at (909)605-1123. If you have anymore questions, feel free to message me back or contact us at (515)-733-2890.

Thanks for shopping with KMJ Performance!

-Mike

Thank you for your inquiry on our Pro Comp LS head studs. To answer your question, if you are unsure on what to torque these to, I would suggest contacting Pro Comp direct, and speaking with a tech. They can be reached at (909)605-1123. If you have anymore questions, feel free to message me back or contact us at (515)-733-2890.

Thanks for shopping with KMJ Performance!

-Mike

#124

#125

TECH Fanatic

iTrader: (35)

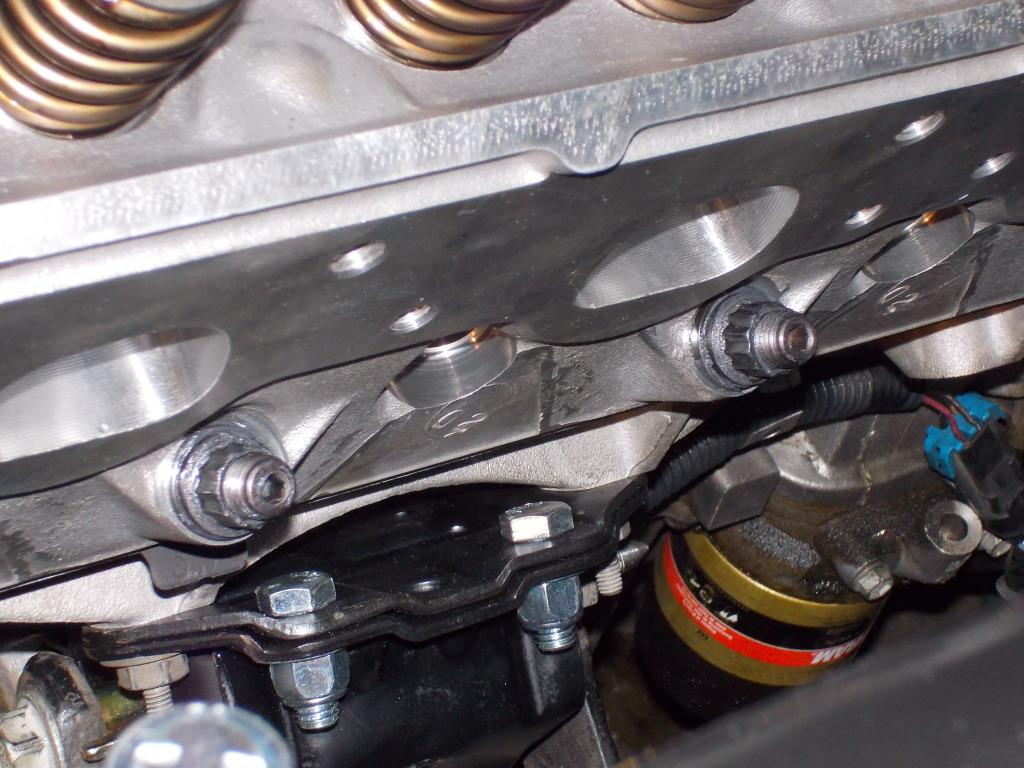

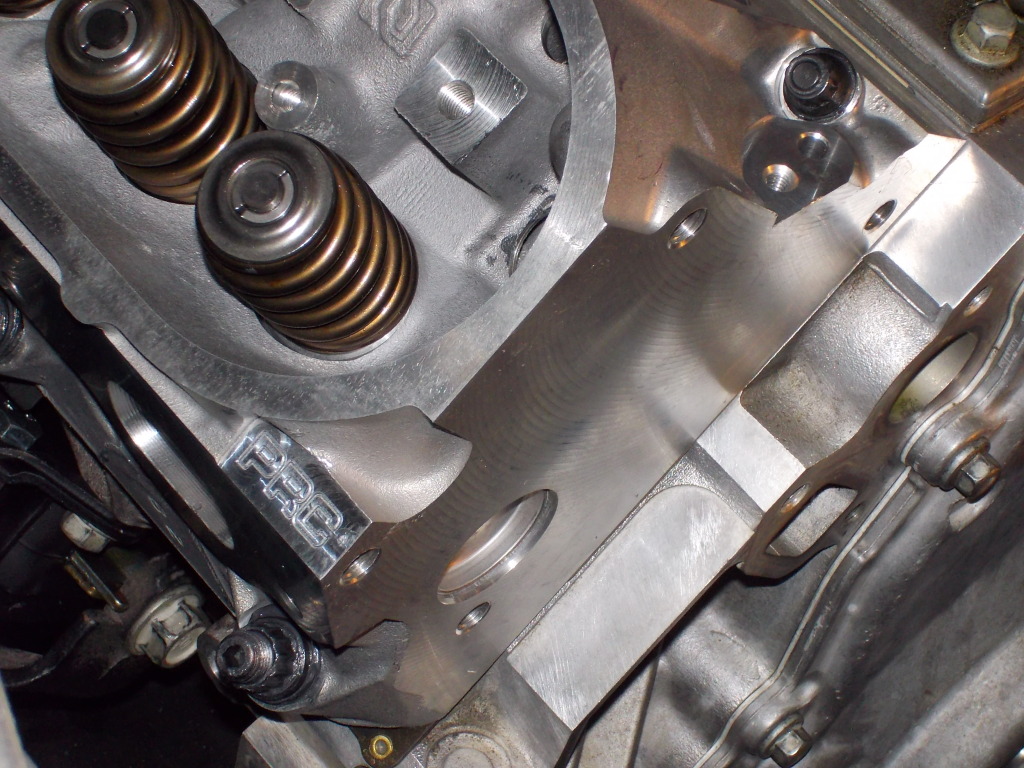

Well I went ahead with the ProComp studs. I was quite pleased with the quality & finish of the kit. I installed finger-tight & torqued them to 25-50-75 ft.-lbs. on the 11mm (7/16") studs and then 18-23 ft.-lbs. on the 8mm (5/16") studs using ARP assembly lube & GM MLS gaskets. The only 'issue' I had is that the end of the 8mm studs do not have a hex to aid installation (not sure if ARP's have this or not). I didn't realize that until after I torqued the 11mm studs, otherwise I would have screwed the the 8mm studs in before putting the head on the block. So I locked two 5/16-24NF jam nuts together on the stud and used them to screw it in. Overall I was happy with the installation.

#132

TECH Junkie

iTrader: (11)

Well I went ahead with the ProComp studs. I was quite pleased with the quality & finish of the kit. I installed finger-tight & torqued them to 25-50-75 ft.-lbs. on the 11mm (7/16") studs and then 18-23 ft.-lbs. on the 8mm (5/16") studs using ARP assembly lube & GM MLS gaskets. The only 'issue' I had is that the end of the 8mm studs do not have a hex to aid installation (not sure if ARP's have this or not). I didn't realize that until after I torqued the 11mm studs, otherwise I would have screwed the the 8mm studs in before putting the head on the block. So I locked two 5/16-24NF jam nuts together on the stud and used them to screw it in. Overall I was happy with the installation.

#137

TECH Junkie

iTrader: (11)

I don't know the numbers for sure, but torque numbers with ARP lube are always lower than plain oil.