5.3 + LQ9 cam + new 862 heads need build advice

#1

Getting parts together for a freshening up of the 5.3. Not planning to pull the crank/rods if I can but might need to do ARP rod bolts in the stock rods as I plan to spin to 6k.

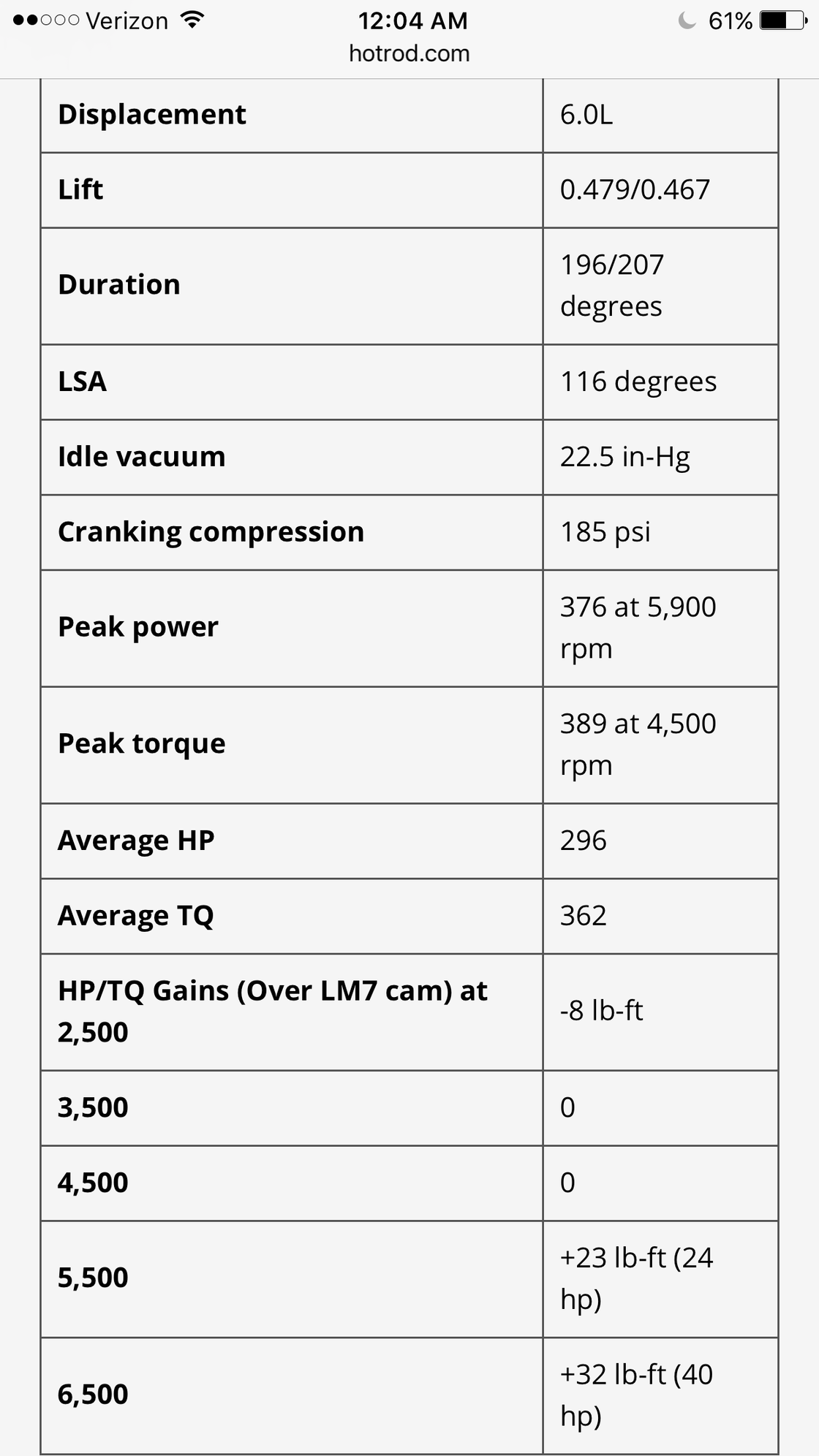

Motor is running good, 99 5.3 with 150k. Long block is OEM stock untouched with 150k. Ive swapped new Fbody oil pan/pickup/windage tray, LS6 blue springs, 72lb bosch injectors, torqstorm supercharger pushing 10psi at 5200rpms. Car has good power but I only have 20psi oil pressure at hot idle with a mix of 20w50 (3 qts) & 10w30 (2 qts) synthetic oil and I wanted to do a freshening up and since I have knotched 862 heads Im going to be replacing them so I can run MLS gaskets. I'm also going to retrofit stock rockers with my straub bushing kits. I don't want to much cam and affect my low RPM power as the car is only street driven with a 2400 stall. I read that the LQ9 cam in a 5.3 only lost 8ftlbs below 2500rpms but gained 40hp at 6k! I was sold. Idled with 22" of vacuum and the lift is low like truck so lifters/LS6 springs will last a long time.

Heres the plan!

1.) Rebuilt 862 heads with no knotches, Going to port them and clean them up, put blue LS6 springs in, MLS head gasket.

2.) Retrofitted stock rockers with straub bushing kit

3.) 5/16" moly pushrods prob 7.4" but will prob measure. or just rock the stockers

4.) LQ9 used cam with 150k

5.) Cloyes stock style LS timing chain

6.) Ebay GM LS7 lifters/trays

7.) GMPP high volume oil pump

8.) Cheap ebay full gasket kit

9.) ARP Head Bolts (no studs or cheap china studs for me)

10.) ARP Rod bolts? Anyone got a part number for stock 5.3 rods?

Do I need to degree the cam? I figured since its OEM I would install it straight up by pulling the old one out and put the new one in.

Anything else? Any complaints/ideas?

Motor is running good, 99 5.3 with 150k. Long block is OEM stock untouched with 150k. Ive swapped new Fbody oil pan/pickup/windage tray, LS6 blue springs, 72lb bosch injectors, torqstorm supercharger pushing 10psi at 5200rpms. Car has good power but I only have 20psi oil pressure at hot idle with a mix of 20w50 (3 qts) & 10w30 (2 qts) synthetic oil and I wanted to do a freshening up and since I have knotched 862 heads Im going to be replacing them so I can run MLS gaskets. I'm also going to retrofit stock rockers with my straub bushing kits. I don't want to much cam and affect my low RPM power as the car is only street driven with a 2400 stall. I read that the LQ9 cam in a 5.3 only lost 8ftlbs below 2500rpms but gained 40hp at 6k! I was sold. Idled with 22" of vacuum and the lift is low like truck so lifters/LS6 springs will last a long time.

Heres the plan!

1.) Rebuilt 862 heads with no knotches, Going to port them and clean them up, put blue LS6 springs in, MLS head gasket.

2.) Retrofitted stock rockers with straub bushing kit

3.) 5/16" moly pushrods prob 7.4" but will prob measure. or just rock the stockers

4.) LQ9 used cam with 150k

5.) Cloyes stock style LS timing chain

6.) Ebay GM LS7 lifters/trays

7.) GMPP high volume oil pump

8.) Cheap ebay full gasket kit

9.) ARP Head Bolts (no studs or cheap china studs for me)

10.) ARP Rod bolts? Anyone got a part number for stock 5.3 rods?

Do I need to degree the cam? I figured since its OEM I would install it straight up by pulling the old one out and put the new one in.

Anything else? Any complaints/ideas?

Last edited by customblackbird; 08-04-2016 at 10:17 AM.

#5

Sorry, my bad lol. I had 5w30 in it and only had like 15psi oil pressure at hot idle at 600rpms. I drained it after 100 miles to clean the junk yard motor out and just put in Valvoline 20w50 synthetic and now have 20psi at idle hot at 600rpms.

Edited the first post.

Edited the first post.

#6

Old School Heavy

iTrader: (16)

Cam Motion offers a line of drop in cams that will work great with your GM performance blue springs. Here is a camshaft that is similar to the one in the test that I would recommend:

http://store.cammotion.com/57-ls1-34...-compression-2

#7

Old School Heavy

iTrader: (16)

Sorry, my bad lol. I had 5w30 in it and only had like 15psi oil pressure at hot idle at 600rpms. I drained it after 100 miles to clean the junk yard motor out and just put in Valvoline 20w50 synthetic and now have 20psi at idle hot at 600rpms.

Edited the first post.

Edited the first post.

Trending Topics

#8

I read that test too. I just went back and looked at it. It says that the LQ9 cam had gained 32 horsepower by 6500 RPM. If you look further down that test, they also had results from a very mild 210 duration aftermarket camshaft that only lost 10 ft pounds of torque at 2500 RPM but gain 80 horsepower by 6500 RPM and 55 horsepower by only 5500 RPM. The aftermarket camshaft also was able to maintain an idle vacuum of over 20". So, if you going to go to the trouble of replacing your camshaft, do you want 32 horsepower or 80 horsepower?

Cam Motion offers a line of drop in cams that will work great with your GM performance blue springs. Here is a camshaft that is similar to the one in the test that I would recommend:

http://store.cammotion.com/57-ls1-34...-compression-2

Cam Motion offers a line of drop in cams that will work great with your GM performance blue springs. Here is a camshaft that is similar to the one in the test that I would recommend:

http://store.cammotion.com/57-ls1-34...-compression-2

Btw at 6500 it was 32ftlb and 40hp.

That cam you linked to was $450 lol... My whole motor with PCM and harness was only $750 lol.

Last edited by customblackbird; 08-02-2016 at 06:02 PM.

#10

While in most cases I would agree with you about the cam and hp due to the annoyance of changing a cam. But what would a larger cam like the one you suggested do in a boosted application? Small cams tend to do better in boost than larger cams as you already know. The added intake duration could increased boost bleed and thus reduce the full hp the cam should provide. I'm not saying that they all don't have their downfalls but for boost things like cams and high flowing heads aren't worth the cost vs just turning up boost. My blower is maxed around 750hp. And my injectors are 72lb and maxed out around 800hp. So I'm limited and it's not an all our crazy build. I had a 521 BBF in the same car and pulled it for this and couldn't be happier.

So the real question is how much hp would the LQ9 cam offer with 10psi over the stock LM7 cam vs an aftermarket.

So the real question is how much hp would the LQ9 cam offer with 10psi over the stock LM7 cam vs an aftermarket.

#11

Old School Heavy

iTrader: (16)

I think you will find that the aftermarket cam that I mentioned will whoop that LQ9 camshaft across the board in your supercharged application too.

With that said, I work at Cam Motion and we could whip you up something custom for your supercharged application that will be even better. I would like to put a 214/226 on 116+5 in there. It will make an even bigger power improvement and still pull great vacuum and drive excellent.

With that said, I work at Cam Motion and we could whip you up something custom for your supercharged application that will be even better. I would like to put a 214/226 on 116+5 in there. It will make an even bigger power improvement and still pull great vacuum and drive excellent.

#13

TECH Veteran

Trickflow have a 216/220 can for 280 bucks shipped from summit..... looks like a solid performer.

#14

~Steven

#15

8 Second Club

iTrader: (4)

I’ve seen your build and it’s a nicely laid out setup with lots of untapped potential. Few points before I get to your list…

I wouldn’t worry about the oil pressure. 20psi is more than enough pressure to keep the bearings happy at 600rpm. What kind of pressure do you have by redline? You can also shim up the relief in the pump you have now. Stock pump should have plenty of volume at 6k and below.

If pressure was a concern, you would replace all the bearings, not throw a high volume oil pump at it. Personally I wouldn’t bother with new bearings on a GEN3 engine. The machine work/labor to do it all properly will cost more than the engine is worth. Cheaper to get another engine. Preferably a GEN4.

If you make large improvements to the engines top end flow, your boost level will drop. You’ll need to pulley up a bit to spin the blower faster to maintain the same boost levels and see big gains. What kind of boost is that blower good for on a 5.3? Will it make more than 10lbs at 6k on a 5.3?

LIST…

If this is a budget minded setup, I think you are over building areas that don't need the attention and spending money in the wrong places to maximize HP gained VS $/time spent. The turbo crowd has proven these engines really don’t need much under 700whp or so.

So if we remove items 1,2,3,5,6,7,9,10. That’s plenty of extra cash to run a decent cam/spring combo. Shouldn’t need to pay more than $350 for a cam IMO. Some of the cheaper cams mentioned above are great. Howards also has some very reasonable grinds.

If it were me…

I wouldn’t bother upgrading the GEN3 engine. Remember If/when the GEN3 motor lets go, it’s likely to damage the cam/heads etc. So having a bunch of money tied up there can bite you.

At 5200 rpm you really aren’t pushing your current setup very hard. I’d install PAC1218 springs, pulley up the blower a little, and run the engine out to 6k the way it sits shooting for 12lbs at 6k. You spent the big bucks on the blower. Make sure you get the most out of it before upgrading other things.

I’d take all the money you would have spent on GEN3 upgrades and look for a nice GEN4 engine instead. Should be able to find them for 500-800 pretty easily. Also don’t shy away from a 4.8. Very underrated on a boosted setup and the extra RPM they are capable of will really shine with a blower. Can also punch one out to a 3.9” bore relatively cheap.

Good luck

I wouldn’t worry about the oil pressure. 20psi is more than enough pressure to keep the bearings happy at 600rpm. What kind of pressure do you have by redline? You can also shim up the relief in the pump you have now. Stock pump should have plenty of volume at 6k and below.

If pressure was a concern, you would replace all the bearings, not throw a high volume oil pump at it. Personally I wouldn’t bother with new bearings on a GEN3 engine. The machine work/labor to do it all properly will cost more than the engine is worth. Cheaper to get another engine. Preferably a GEN4.

If you make large improvements to the engines top end flow, your boost level will drop. You’ll need to pulley up a bit to spin the blower faster to maintain the same boost levels and see big gains. What kind of boost is that blower good for on a 5.3? Will it make more than 10lbs at 6k on a 5.3?

LIST…

If this is a budget minded setup, I think you are over building areas that don't need the attention and spending money in the wrong places to maximize HP gained VS $/time spent. The turbo crowd has proven these engines really don’t need much under 700whp or so.

1.) Rebuilt 862 heads with no notches, Going to port them and clean them up, put blue LS6 springs in, MLS head gasket.

(Can’t go wrong updating heads, but if they aren’t leaking is it really necessary? What kind of power will you really gain VS the work/time invested? 10-20hp maybe? Turbo guys have made 700+WHP on the graphite/non-MLS head gaskets on factory head bolts and had no sealing issues. If they aren’t leaking, you may want to leave them alone.

I’d suggest a PAC1218 spring at minimum, no matter what head/gasket you go with. They are a direct drop in, about $140, and will allow you to run 6000 easy with a decent cam. Whether now or down the road.

2.) Retrofitted stock rockers with straub bushing kit (Completely unnecessary w/ a 6k redline, factory valve train is more than adequate)

3.) 5/16" moly pushrods (Completely unnecessary w/ a 6k redline)

4.) LQ9 used cam with 150k

(This is the one area to spend money IMO. A good cam and springs will net you the most noticeable gains, just don’t go overboard. The added cost to run a “BIG” aggressive cam adds up quick. Something like the JFR triple 12 grind ($365) will noticeably wake the engine up over the Lq9 grind, and not give up any low end. For a budget minded build you want a cam that can be easily run on the OEM valve train IMO. I ran the Triple 12 grind to 6800 on a 5.3 and a 4.8 at 25lbs of boost on a 100% original factory valve train with PAC1218 springs. With a 6k self-imposed redline, there’s no reason for aftermarket valve train parts.

5.) Cloyes stock style LS timing chain ((Completely unnecessary w/ a 6k redline) Buy OEM GM gears and GEN4 style GM chain. (Ebay)

6.) Ebay GM LS7 lifters/trays (Lifters probably aren’t needed, but never a bad idea. New trays are rarely needed. I’ve reused the same sets many times.

7.) GMPP high volume oil pump (Completely unnecessary w/ a 6k redline. Robs more power to turn. Likely to cause oil pan pickup issues if you run a LS1 or center sump pan. Zero reason for an aftermarket oil pump with a 6k redline.

8.) Cheap ebay full gasket kit ( OK, but probably not necessary)

9.) ARP Head Bolts (Completely unnecessary. New OEM TTY bolts are more than adequate and cheap. With a good LS9 MLS gasket I’ve seen 800+whp on reused factory head bolts) For a budget build under 700whp aftermarket head hardware just isn’t needed IMO. If money isn’t a concern go with an ARP stud set, not bolts.

10.) ARP Rod bolts? Anyone got a part number for stock 5.3 rods? (Completely unnecessary w/ a 6k redline) Also rods should be honed with ARP fasters installed, they can “egg” the big end of the rod. Giant waste of money IMO. I’ve routinely spun my turbo engines to 6800-7000 on both gen3 and gen4 OEM rod bolts and BIG boost.

(Can’t go wrong updating heads, but if they aren’t leaking is it really necessary? What kind of power will you really gain VS the work/time invested? 10-20hp maybe? Turbo guys have made 700+WHP on the graphite/non-MLS head gaskets on factory head bolts and had no sealing issues. If they aren’t leaking, you may want to leave them alone.

I’d suggest a PAC1218 spring at minimum, no matter what head/gasket you go with. They are a direct drop in, about $140, and will allow you to run 6000 easy with a decent cam. Whether now or down the road.

2.) Retrofitted stock rockers with straub bushing kit (Completely unnecessary w/ a 6k redline, factory valve train is more than adequate)

3.) 5/16" moly pushrods (Completely unnecessary w/ a 6k redline)

4.) LQ9 used cam with 150k

(This is the one area to spend money IMO. A good cam and springs will net you the most noticeable gains, just don’t go overboard. The added cost to run a “BIG” aggressive cam adds up quick. Something like the JFR triple 12 grind ($365) will noticeably wake the engine up over the Lq9 grind, and not give up any low end. For a budget minded build you want a cam that can be easily run on the OEM valve train IMO. I ran the Triple 12 grind to 6800 on a 5.3 and a 4.8 at 25lbs of boost on a 100% original factory valve train with PAC1218 springs. With a 6k self-imposed redline, there’s no reason for aftermarket valve train parts.

5.) Cloyes stock style LS timing chain ((Completely unnecessary w/ a 6k redline) Buy OEM GM gears and GEN4 style GM chain. (Ebay)

6.) Ebay GM LS7 lifters/trays (Lifters probably aren’t needed, but never a bad idea. New trays are rarely needed. I’ve reused the same sets many times.

7.) GMPP high volume oil pump (Completely unnecessary w/ a 6k redline. Robs more power to turn. Likely to cause oil pan pickup issues if you run a LS1 or center sump pan. Zero reason for an aftermarket oil pump with a 6k redline.

8.) Cheap ebay full gasket kit ( OK, but probably not necessary)

9.) ARP Head Bolts (Completely unnecessary. New OEM TTY bolts are more than adequate and cheap. With a good LS9 MLS gasket I’ve seen 800+whp on reused factory head bolts) For a budget build under 700whp aftermarket head hardware just isn’t needed IMO. If money isn’t a concern go with an ARP stud set, not bolts.

10.) ARP Rod bolts? Anyone got a part number for stock 5.3 rods? (Completely unnecessary w/ a 6k redline) Also rods should be honed with ARP fasters installed, they can “egg” the big end of the rod. Giant waste of money IMO. I’ve routinely spun my turbo engines to 6800-7000 on both gen3 and gen4 OEM rod bolts and BIG boost.

If it were me…

I wouldn’t bother upgrading the GEN3 engine. Remember If/when the GEN3 motor lets go, it’s likely to damage the cam/heads etc. So having a bunch of money tied up there can bite you.

At 5200 rpm you really aren’t pushing your current setup very hard. I’d install PAC1218 springs, pulley up the blower a little, and run the engine out to 6k the way it sits shooting for 12lbs at 6k. You spent the big bucks on the blower. Make sure you get the most out of it before upgrading other things.

I’d take all the money you would have spent on GEN3 upgrades and look for a nice GEN4 engine instead. Should be able to find them for 500-800 pretty easily. Also don’t shy away from a 4.8. Very underrated on a boosted setup and the extra RPM they are capable of will really shine with a blower. Can also punch one out to a 3.9” bore relatively cheap.

Good luck

Last edited by Forcefed86; 08-03-2016 at 04:19 PM.

#16

Apparently I must have been drunk or just checked out mentally when writing the post or for that day or two bc I completely forgot what oil I was using lol.

I updated the original post but I drained the pan of 5w30 conventional. Left the filter in with the oil in the filter bc it only had 100 miles on it.

This is what I put in.

3 qts of 20w50 Valvoline synthetic

2 qts of 10w30 Valvoline synthetic

So 5 qts total plus the original 5w30 in the filter. so I would say 5.5qts total. I would say the mix would net me a 15w40 average oil weight. I only used this because this is what I had laying around.

Oil pressure is like 40 when cold start idle (70-90*F outside). Hot idle is like 20-25psi via my electronic speedhut gauge. I will have to put on a mechanical that I have to verify. Step on the throttle and oil pressure climbs to 40psi on the throttle.

#17

Old School Heavy

iTrader: (16)

Apparently I must have been drunk or just checked out mentally when writing the post or for that day or two bc I completely forgot what oil I was using lol.

I updated the original post but I drained the pan of 5w30 conventional. Left the filter in with the oil in the filter bc it only had 100 miles on it.

This is what I put in.

3 qts of 20w50 Valvoline synthetic

2 qts of 10w30 Valvoline synthetic

So 5 qts total plus the original 5w30 in the filter. so I would say 5.5qts total. I would say the mix would net me a 15w40 average oil weight. I only used this because this is what I had laying around.

Oil pressure is like 40 when cold start idle (70-90*F outside). Hot idle is like 20-25psi via my electronic speedhut gauge. I will have to put on a mechanical that I have to verify. Step on the throttle and oil pressure climbs to 40psi on the throttle.

I updated the original post but I drained the pan of 5w30 conventional. Left the filter in with the oil in the filter bc it only had 100 miles on it.

This is what I put in.

3 qts of 20w50 Valvoline synthetic

2 qts of 10w30 Valvoline synthetic

So 5 qts total plus the original 5w30 in the filter. so I would say 5.5qts total. I would say the mix would net me a 15w40 average oil weight. I only used this because this is what I had laying around.

Oil pressure is like 40 when cold start idle (70-90*F outside). Hot idle is like 20-25psi via my electronic speedhut gauge. I will have to put on a mechanical that I have to verify. Step on the throttle and oil pressure climbs to 40psi on the throttle.

#18

We can make that custom camshaft for you in 5150 steel alloy for $399. I can make it so that will work with the GM Performance springs or I can make it more aggressive for use with a good double springs. I prefer good double springs in a performance application, but I understand budget constraints as well. Whatever you prefer.

~Steven

~Steven

Double springs = $ plus added stress on lifters and require better pushrods. If I can spin the stock LS6 springs with cam to 6K @ 10psi with no float I would be happy.

#19

If it were mine, I would verify with a mechanical gauge, cut the oil filter open and and inspect the element and listen carefully for any odd noises. If all that is good, I would run it without worry. Just keep an eye on the oil pressure to make sure it doesn't start falling off.

So no need for the HV pump then?

#20

I’ve seen your build and it’s a nicely laid out setup with lots of untapped potential. Few points before I get to your list…

I wouldn’t worry about the oil pressure. 20psi is more than enough pressure to keep the bearings happy at 600rpm. What kind of pressure do you have by redline? You can also shim up the relief in the pump you have now. Stock pump should have plenty of volume at 6k and below.

Understood, I'm used to SBC and BBF so 20psi hot idle isn't great. I will prob leave it alone at this point. I would say I'm not looking at the oil pressure at 5k and under boost but its at 40psi regularly when I'm on the throttle right off idle.

If pressure was a concern, you would replace all the bearings, not throw a high volume oil pump at it. Personally I wouldn’t bother with new bearings on a GEN3 engine. The machine work/labor to do it all properly will cost more than the engine is worth. Cheaper to get another engine. Preferably a GEN4.

Exactly My point. Motor cost me $750 total Hence Why I can't justify a $400 cam, $150 lifter, $100 pushrods and $250+ springs when I'm not pulling the oil pump or changing the bearings. However for me to pull the heads I automatically need new gaskets... the knotched heads require graphite gaskets which aren't easy to get and I think only victor reinz and cheap domestic gaskets on ebay are available. Which Ive heard hit or miss about the ebay gaskets. Since I would go new lifters/trays etc it would be smart to just have the heads freshened up... valve job, guides checked, seals, cleaned and then throw some light home porting at them. But all this adds up and i'm still stuck with the shitty knotched heads. So getting already rebuilt heads with no knotches is definitely going to happen as I want to run MLS gaskets for piece of mind and an overall better seal to limit the possibility of me having to tear it all apart again. Dissasmbling the the heads for port work is just time since all the freshening has been done. Throw $60 LS6 spring on them and let them eat. Ported heads and the stock cam would likely show improvements on their own but obviously a cam would improve them even more.

If you make large improvements to the engines top end flow, your boost level will drop. You’ll need to pulley up a bit to spin the blower faster to maintain the same boost levels and see big gains. What kind of boost is that blower good for on a 5.3? Will it make more than 10lbs at 6k on a 5.3?

This is very true and a welcomed truth. Running 10psi now is 10psi to make 500ish hp. If I could make 600hp on 6-8psi I would be more happy. I dont need high boost numbers, that doesnt mean squat to me, low boost is better anyway for tuning purposes and lowering engine/IAT temps etc. My blower (torqstorm) is only good for about 700-750hp estimated, I run the smallest pulley I can which is why my boost is at 10psi at 5k. I was told it should make 10-12psi on a stock 5.3. I have been getting some belt slip at 5k at 7-9psi depending on load and how much throttle I have in it. But I have visually seen 10psi on my innovate gauge but the logs only showed 9.8psi or something. Gona crank the belt a smidge more. The added benefit of lower boost but more HP means the less chance for belt slip. I dont get belt slip until over 7psi sometimes, they told me its hard to keep the small 3" pulley from slipping at higher boost. To keep the boost in the 6-8 means I'm less likely to get slip. The boost only allows me to run a very tame stock motor for driveability while the boost gives me the power I want when I want to get on it. Its actually a great setup honestly and couldnt be happier. I'm still tempted to change the heads and lifters/trays and throw it all back together just to freshen the top end up and just leave the cam. The cam part is annoying as I have to pull the front cover.

LIST…

If this is a budget minded setup, I think you are over building areas that don't need the attention and spending money in the wrong places to maximize HP gained VS $/time spent. The turbo crowd has proven these engines really don’t need much under 700whp or so.

I agree, some things I'm throwing in to get an idea of what I need. Turbos have the advantage of no power loss. I'm loosing about 50hp just to turn the supercharger at full boost. I just want a bump in top end while decreasing boost required to make more hp but keeping reliability and driveability the same. It cant be a dog below 3k, it can't idle like crap and Id be happy with 500rwhp. Honestly if I didnt have to touch the tune I'd be happy as well.

So if we remove items 1,2,3,5,6,7,9,10. That’s plenty of extra cash to run a decent cam/spring combo. Shouldn’t need to pay more than $350 for a cam IMO. Some of the cheaper cams mentioned above are great. Howards also has some very reasonable grinds.

Thats everything lol. My valvetrain is not quiet, its not loud either... but 150k the stock parts are worn and here I am doubling its engine output after 150k of someone beating on it in stock form.

If it were me…

I wouldn’t bother upgrading the GEN3 engine. Remember If/when the GEN3 motor lets go, it’s likely to damage the cam/heads etc. So having a bunch of money tied up there can bite you.

True, which is why I dont want alot of money in the valvetrain as thats usually a part that lets go first or gets destroyed. The heads are cheap at $350 for a rebuilt set, throw $60 in springs and at $410 I have new heads that I will port for more flow (lower boost). ARP bolts (no need for studs) will offer the ease of just torquing to ftlbs (plus added clamping) vs having to deal with tq to yield fasteners and all that crap, plus they are resuable. Ebay china studs scare me bc it they fail your stuck with a torched head/deck, block ruined, piston gone etc. rather just spend the $130-180 for ARP bolts.

At 5200 rpm you really aren’t pushing your current setup very hard. I’d install PAC1218 springs, pulley up the blower a little, and run the engine out to 6k the way it sits shooting for 12lbs at 6k. You spent the big bucks on the blower. Make sure you get the most out of it before upgrading other things.

Dont the Gen 3 have press fit pistons and the shitty rod bolts? I thought spinning the gen 3 above 5500 is pushing your luck. I agree about not pushing it hard, I would like to be able to spin to 6k when wanted and the motors current cam is all done by 5200. I can't increase boost anymore, smallest pulley installed. The blower brand new only cost 3k complete... its a cheap little blower but high quality, only issue is your limited on power. Its a street blower so it makes boost very quickly which makes it fun.

I’d take all the money you would have spent on GEN3 upgrades and look for a nice GEN4 engine instead. Should be able to find them for 500-800 pretty easily. Also don’t shy away from a 4.8. Very underrated on a boosted setup and the extra RPM they are capable of will really shine with a blower. Can also punch one out to a 3.9” bore relatively cheap.

Always keeping an eye out, almost picked up a 6.0 a couple of times. I still dont feel like I'd push this gen 3 motor hard enough to warrant the strength of a gen4. Feel like the gen 3 limits are the rods/pistons. Going to a gen 4 would mean if I got a custom cam for my gen 3 it wouldnt be transferable to the gen 4 block due to cam sensor placement etc.

Good luck

I wouldn’t worry about the oil pressure. 20psi is more than enough pressure to keep the bearings happy at 600rpm. What kind of pressure do you have by redline? You can also shim up the relief in the pump you have now. Stock pump should have plenty of volume at 6k and below.

Understood, I'm used to SBC and BBF so 20psi hot idle isn't great. I will prob leave it alone at this point. I would say I'm not looking at the oil pressure at 5k and under boost but its at 40psi regularly when I'm on the throttle right off idle.

If pressure was a concern, you would replace all the bearings, not throw a high volume oil pump at it. Personally I wouldn’t bother with new bearings on a GEN3 engine. The machine work/labor to do it all properly will cost more than the engine is worth. Cheaper to get another engine. Preferably a GEN4.

Exactly My point. Motor cost me $750 total Hence Why I can't justify a $400 cam, $150 lifter, $100 pushrods and $250+ springs when I'm not pulling the oil pump or changing the bearings. However for me to pull the heads I automatically need new gaskets... the knotched heads require graphite gaskets which aren't easy to get and I think only victor reinz and cheap domestic gaskets on ebay are available. Which Ive heard hit or miss about the ebay gaskets. Since I would go new lifters/trays etc it would be smart to just have the heads freshened up... valve job, guides checked, seals, cleaned and then throw some light home porting at them. But all this adds up and i'm still stuck with the shitty knotched heads. So getting already rebuilt heads with no knotches is definitely going to happen as I want to run MLS gaskets for piece of mind and an overall better seal to limit the possibility of me having to tear it all apart again. Dissasmbling the the heads for port work is just time since all the freshening has been done. Throw $60 LS6 spring on them and let them eat. Ported heads and the stock cam would likely show improvements on their own but obviously a cam would improve them even more.

If you make large improvements to the engines top end flow, your boost level will drop. You’ll need to pulley up a bit to spin the blower faster to maintain the same boost levels and see big gains. What kind of boost is that blower good for on a 5.3? Will it make more than 10lbs at 6k on a 5.3?

This is very true and a welcomed truth. Running 10psi now is 10psi to make 500ish hp. If I could make 600hp on 6-8psi I would be more happy. I dont need high boost numbers, that doesnt mean squat to me, low boost is better anyway for tuning purposes and lowering engine/IAT temps etc. My blower (torqstorm) is only good for about 700-750hp estimated, I run the smallest pulley I can which is why my boost is at 10psi at 5k. I was told it should make 10-12psi on a stock 5.3. I have been getting some belt slip at 5k at 7-9psi depending on load and how much throttle I have in it. But I have visually seen 10psi on my innovate gauge but the logs only showed 9.8psi or something. Gona crank the belt a smidge more. The added benefit of lower boost but more HP means the less chance for belt slip. I dont get belt slip until over 7psi sometimes, they told me its hard to keep the small 3" pulley from slipping at higher boost. To keep the boost in the 6-8 means I'm less likely to get slip. The boost only allows me to run a very tame stock motor for driveability while the boost gives me the power I want when I want to get on it. Its actually a great setup honestly and couldnt be happier. I'm still tempted to change the heads and lifters/trays and throw it all back together just to freshen the top end up and just leave the cam. The cam part is annoying as I have to pull the front cover.

LIST…

If this is a budget minded setup, I think you are over building areas that don't need the attention and spending money in the wrong places to maximize HP gained VS $/time spent. The turbo crowd has proven these engines really don’t need much under 700whp or so.

I agree, some things I'm throwing in to get an idea of what I need. Turbos have the advantage of no power loss. I'm loosing about 50hp just to turn the supercharger at full boost. I just want a bump in top end while decreasing boost required to make more hp but keeping reliability and driveability the same. It cant be a dog below 3k, it can't idle like crap and Id be happy with 500rwhp. Honestly if I didnt have to touch the tune I'd be happy as well.

So if we remove items 1,2,3,5,6,7,9,10. That’s plenty of extra cash to run a decent cam/spring combo. Shouldn’t need to pay more than $350 for a cam IMO. Some of the cheaper cams mentioned above are great. Howards also has some very reasonable grinds.

Thats everything lol. My valvetrain is not quiet, its not loud either... but 150k the stock parts are worn and here I am doubling its engine output after 150k of someone beating on it in stock form.

If it were me…

I wouldn’t bother upgrading the GEN3 engine. Remember If/when the GEN3 motor lets go, it’s likely to damage the cam/heads etc. So having a bunch of money tied up there can bite you.

True, which is why I dont want alot of money in the valvetrain as thats usually a part that lets go first or gets destroyed. The heads are cheap at $350 for a rebuilt set, throw $60 in springs and at $410 I have new heads that I will port for more flow (lower boost). ARP bolts (no need for studs) will offer the ease of just torquing to ftlbs (plus added clamping) vs having to deal with tq to yield fasteners and all that crap, plus they are resuable. Ebay china studs scare me bc it they fail your stuck with a torched head/deck, block ruined, piston gone etc. rather just spend the $130-180 for ARP bolts.

At 5200 rpm you really aren’t pushing your current setup very hard. I’d install PAC1218 springs, pulley up the blower a little, and run the engine out to 6k the way it sits shooting for 12lbs at 6k. You spent the big bucks on the blower. Make sure you get the most out of it before upgrading other things.

Dont the Gen 3 have press fit pistons and the shitty rod bolts? I thought spinning the gen 3 above 5500 is pushing your luck. I agree about not pushing it hard, I would like to be able to spin to 6k when wanted and the motors current cam is all done by 5200. I can't increase boost anymore, smallest pulley installed. The blower brand new only cost 3k complete... its a cheap little blower but high quality, only issue is your limited on power. Its a street blower so it makes boost very quickly which makes it fun.

I’d take all the money you would have spent on GEN3 upgrades and look for a nice GEN4 engine instead. Should be able to find them for 500-800 pretty easily. Also don’t shy away from a 4.8. Very underrated on a boosted setup and the extra RPM they are capable of will really shine with a blower. Can also punch one out to a 3.9” bore relatively cheap.

Always keeping an eye out, almost picked up a 6.0 a couple of times. I still dont feel like I'd push this gen 3 motor hard enough to warrant the strength of a gen4. Feel like the gen 3 limits are the rods/pistons. Going to a gen 4 would mean if I got a custom cam for my gen 3 it wouldnt be transferable to the gen 4 block due to cam sensor placement etc.

Good luck