First LS build

#36

Went into the shop this afternoon to clean and check the spring install height and seat pressure. Got the install height 1.850, but the spring tester wasn't working for me. So I'll have to retest agian Monday. And I'm pretty sure I was not using the height gauge right. I did put the heads in a solvent bath for about an hour just to make sure they were really clean.

Last edited by madsv1000; 09-17-2016 at 06:14 PM.

#37

Went into the shop this afternoon to clean and check the spring install height and seat pressure. Got the install height 1.850, but the spring tester wasn't working for me. So I'll have to retest agian Monday. And I'm pretty sure I was not using the height gauge right. I did put the heads in a solvent bath for about an hour just to make sure they were really clean.

#39

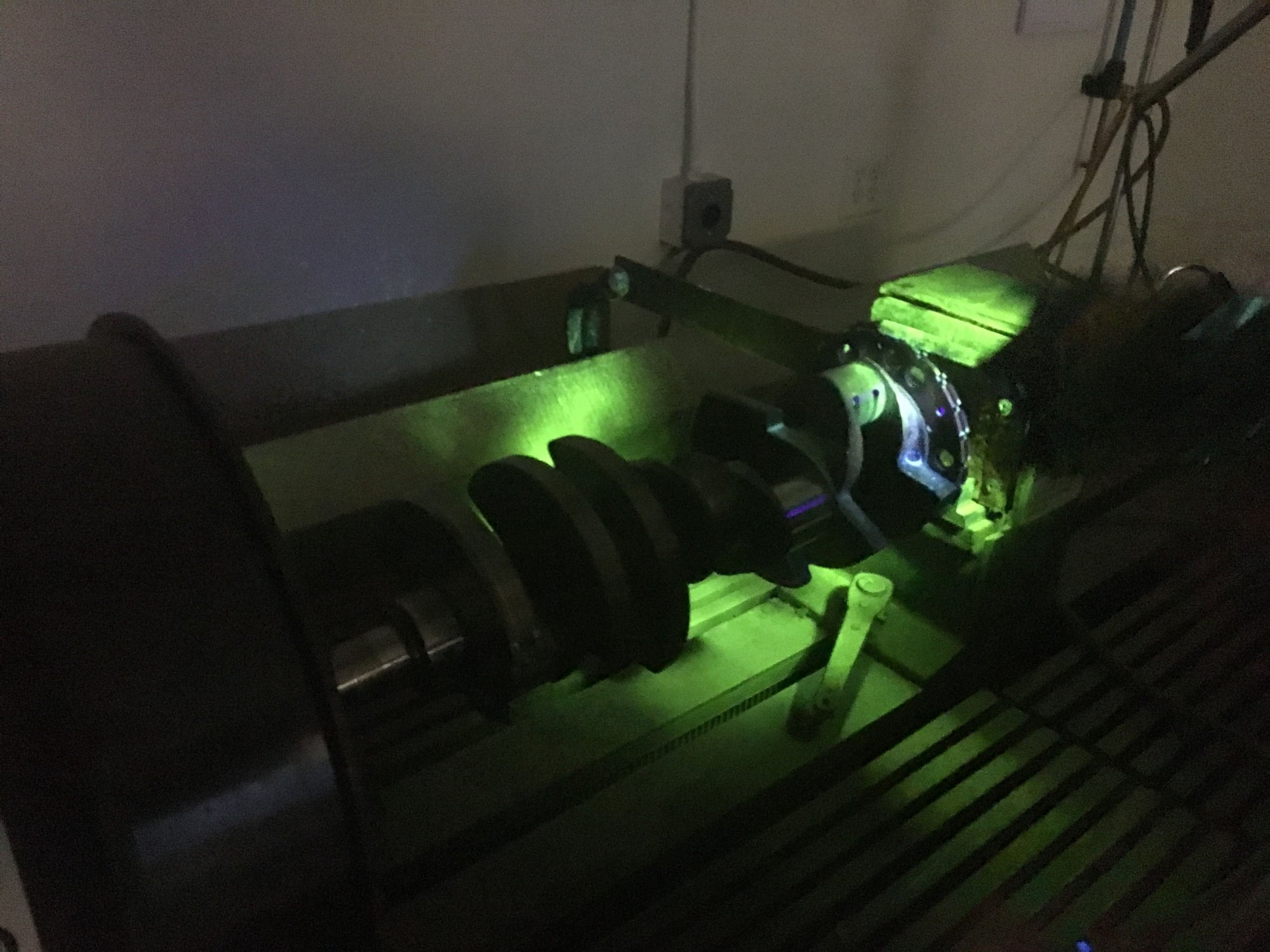

Went into the shop this morning and ported and shimmed my oil pump. Amazing what a few minutes of work can do for the entrance and exit of it. Rods came in yesterday and bought a set of pushrods to go with the cam I've finally settled on. 227/235 @ .050 .614/.621 lift on 113