New LS7 Build

#1

So Iíve been lurking over here for about a year, learning as much as I can from you guys. Now that my motor is about done, I wanted to post some details and get your feedback. Iím no LS pro by a long shot and still learning as I go.

A little backgroundÖ.me and a few buddies hang out here to figure out how to build strong LS motors to stuff into our retro cars. Mostly used for AutoX and time trials, we attend local track days, SCCA/NMCA and Streetcar events. These events are formerly called ĎRun To Theí (RTTx) events, such as Run to the Hills, Run to the Coast, etc. They are now rebranded as American Street Car Series (americanstreetcarseries.com). Most of us hang out at Protouring.com or Lareral-G.net. For the most part the motors are built not for drag racing 8k top end, but more for fast revving in-n-out of corners torque. My goal was to build a bullet proof (no such thing!) LS7, or at least take out some of the documented weaknesses. I started w a flea-bay motor some knucklehead built wrong. I bought it knowing I would tear it down and rebuild it as strong as possible for the planned abuse. Last thing I wanted was a rod grenading the side of the block or needle bearings falling through the rotating assy under power. I wanted it to breathe good, accelerate quick and rev to 7k on the straights. I didnít sleeve it, although I did speak to RED Steve and one day Iíll beef up the block a little (meaning the motor will be rebuilt at some point, planned or forced).

According to Ovrkill, hereís my Ďpunyí motor (hey Brent!). All the work was done at QMP Racing in Chatsworth, CA. Iíve known Brad and Mikey for a loooong time and consider them friends. These guys really know their stuff and everything is done in house. On any given week youíll see small blocks, big blocks, turbo/blower builds, a Lambo rebuild or one of those Sonny-whats-his-names 800 cu alum motors! That thing is huge BTWÖ

I started w a stock GM LS7 crate motor. Block was CNC blueprinted, diamond honed, decked, align honed, Cam tunnel bored. We balanced the factory forged crank and added Crower billet steel connecting rods, ROSS custom pistons and pins, and a set of Total Seal custom rings. ARP main bearing studs hold it all together. Iíve got a 13 lb Fidanze alum flywheel and a McLeod RST clamp Iíll throw on when the time comes.

Heads were fully prepped w CNC port to breathe 390 cfm @ .0600. Milled and given their competition valve job. We kept the Titanium valves and added Manley Titanium spring cups , retainers, pushrods and polished valve springs. CHE bushed rockers help delete those pesky needle bearings. We also used some of those new Comp short throw lifters (tray type) to see if they truly help the motor build revs faster and control any valve float.

Tieing the two together is a Comp bump stick. 235/244, 630 lift w a 113+2 LSA. Brad cam doctored it as he always does and this is the formula for my intended use.

For oiling Iím using an LS9 pump, Avaid pan baffle, Peterson baffled tank and breather. These cars donít quite pull like race prepped Vetts so I think I should be good.

Up top Iíve got a Mamo ported factory intake, Fast rails and a BER ported TB. We threw a set of Fast flow matched injectors pumping 65 psi just in case I decide to add some cubes or something later on down the road.

Here's some pics...

A little backgroundÖ.me and a few buddies hang out here to figure out how to build strong LS motors to stuff into our retro cars. Mostly used for AutoX and time trials, we attend local track days, SCCA/NMCA and Streetcar events. These events are formerly called ĎRun To Theí (RTTx) events, such as Run to the Hills, Run to the Coast, etc. They are now rebranded as American Street Car Series (americanstreetcarseries.com). Most of us hang out at Protouring.com or Lareral-G.net. For the most part the motors are built not for drag racing 8k top end, but more for fast revving in-n-out of corners torque. My goal was to build a bullet proof (no such thing!) LS7, or at least take out some of the documented weaknesses. I started w a flea-bay motor some knucklehead built wrong. I bought it knowing I would tear it down and rebuild it as strong as possible for the planned abuse. Last thing I wanted was a rod grenading the side of the block or needle bearings falling through the rotating assy under power. I wanted it to breathe good, accelerate quick and rev to 7k on the straights. I didnít sleeve it, although I did speak to RED Steve and one day Iíll beef up the block a little (meaning the motor will be rebuilt at some point, planned or forced).

According to Ovrkill, hereís my Ďpunyí motor (hey Brent!). All the work was done at QMP Racing in Chatsworth, CA. Iíve known Brad and Mikey for a loooong time and consider them friends. These guys really know their stuff and everything is done in house. On any given week youíll see small blocks, big blocks, turbo/blower builds, a Lambo rebuild or one of those Sonny-whats-his-names 800 cu alum motors! That thing is huge BTWÖ

I started w a stock GM LS7 crate motor. Block was CNC blueprinted, diamond honed, decked, align honed, Cam tunnel bored. We balanced the factory forged crank and added Crower billet steel connecting rods, ROSS custom pistons and pins, and a set of Total Seal custom rings. ARP main bearing studs hold it all together. Iíve got a 13 lb Fidanze alum flywheel and a McLeod RST clamp Iíll throw on when the time comes.

Heads were fully prepped w CNC port to breathe 390 cfm @ .0600. Milled and given their competition valve job. We kept the Titanium valves and added Manley Titanium spring cups , retainers, pushrods and polished valve springs. CHE bushed rockers help delete those pesky needle bearings. We also used some of those new Comp short throw lifters (tray type) to see if they truly help the motor build revs faster and control any valve float.

Tieing the two together is a Comp bump stick. 235/244, 630 lift w a 113+2 LSA. Brad cam doctored it as he always does and this is the formula for my intended use.

For oiling Iím using an LS9 pump, Avaid pan baffle, Peterson baffled tank and breather. These cars donít quite pull like race prepped Vetts so I think I should be good.

Up top Iíve got a Mamo ported factory intake, Fast rails and a BER ported TB. We threw a set of Fast flow matched injectors pumping 65 psi just in case I decide to add some cubes or something later on down the road.

Here's some pics...

#4

On The Tree

iTrader: (2)

Join Date: Jan 2012

Location: Alabama

Posts: 196

Likes: 0

Received 0 Likes

on

0 Posts

Looking at an LS7 build myself. Why the additional block prep? I have asked Scoggins dickey and GMPP, the blocks are supposed to be RTA.

And what are the needle bearings you are referring to, from cam bearings?

And what are the needle bearings you are referring to, from cam bearings?

#5

thanks,

Jim

#6

No idea what he was referring to w 'RTA'. IMO extra block prep = tighter tolerances for a better running motor under harsh conditions. I'm no machinist but barrels do get off center (I'm told) so CNC blueprinting helps for a good starting point.

Trending Topics

#9

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

So Iíve been lurking over here for about a year, learning as much as I can from you guys. Now that my motor is about done, I wanted to post some details and get your feedback. Iím no LS pro by a long shot and still learning as I go.

A little backgroundÖ.me and a few buddies hang out here to figure out how to build strong LS motors to stuff into our retro cars. Mostly used for AutoX and time trials, we attend local track days, SCCA/NMCA and Streetcar events. These events are formerly called ĎRun To Theí (RTTx) events, such as Run to the Hills, Run to the Coast, etc. They are now rebranded as American Street Car Series (americanstreetcarseries.com). Most of us hang out at Protouring.com or Lareral-G.net. For the most part the motors are built not for drag racing 8k top end, but more for fast revving in-n-out of corners torque. My goal was to build a bullet proof (no such thing!) LS7, or at least take out some of the documented weaknesses. I started w a flea-bay motor some knucklehead built wrong. I bought it knowing I would tear it down and rebuild it as strong as possible for the planned abuse. Last thing I wanted was a rod grenading the side of the block or needle bearings falling through the rotating assy under power. I wanted it to breathe good, accelerate quick and rev to 7k on the straights. I didnít sleeve it, although I did speak to RED Steve and one day Iíll beef up the block a little (meaning the motor will be rebuilt at some point, planned or forced).

According to Ovrkill, hereís my Ďpunyí motor (hey Brent!). All the work was done at QMP Racing in Chatsworth, CA. Iíve known Brad and Mikey for a loooong time and consider them friends. These guys really know their stuff and everything is done in house. On any given week youíll see small blocks, big blocks, turbo/blower builds, a Lambo rebuild or one of those Sonny-whats-his-names 800 cu alum motors! That thing is huge BTWÖ

I started with a stock GM LS7 crate motor. Block was CNC blueprinted, diamond honed, decked, align honed, Cam tunnel bored. We balanced the factory forged crank and added Crower billet steel connecting rods, ROSS custom pistons and pins, and a set of Total Seal custom rings. ARP main bearing studs hold it all together. Iíve got a 13 lb Fidanza aluminum flywheel and a McLeod RST clamp Iíll throw on when the time comes.

Heads were fully prepped w CNC port to breathe 390 cfm @ .0600. Milled and given their competition valve job. We kept the Titanium valves and added Manley Titanium spring cups , retainers, pushrods and polished valve springs. CHE bushed rockers help delete those pesky needle bearings. We also used some of those new Comp short throw lifters (tray type) to see if they truly help the motor build revs faster and control any valve float.

Tieing the two together is a Comp bump stick. 235/244, 630 lift w a 113+2 LSA. Brad cam doctored it as he always does and this is the formula for my intended use.

For oiling Iím using an LS9 pump, Avaid pan baffle, Peterson baffled tank and breather. These cars donít quite pull like race prepped Vetts so I think I should be good.

Up top Iíve got a Mamo ported factory intake, Fast rails and a BER ported TB. We threw a set of Fast flow matched injectors pumping 65 psi just in case I decide to add some cubes or something later on down the road.

Here's some pics...

A little backgroundÖ.me and a few buddies hang out here to figure out how to build strong LS motors to stuff into our retro cars. Mostly used for AutoX and time trials, we attend local track days, SCCA/NMCA and Streetcar events. These events are formerly called ĎRun To Theí (RTTx) events, such as Run to the Hills, Run to the Coast, etc. They are now rebranded as American Street Car Series (americanstreetcarseries.com). Most of us hang out at Protouring.com or Lareral-G.net. For the most part the motors are built not for drag racing 8k top end, but more for fast revving in-n-out of corners torque. My goal was to build a bullet proof (no such thing!) LS7, or at least take out some of the documented weaknesses. I started w a flea-bay motor some knucklehead built wrong. I bought it knowing I would tear it down and rebuild it as strong as possible for the planned abuse. Last thing I wanted was a rod grenading the side of the block or needle bearings falling through the rotating assy under power. I wanted it to breathe good, accelerate quick and rev to 7k on the straights. I didnít sleeve it, although I did speak to RED Steve and one day Iíll beef up the block a little (meaning the motor will be rebuilt at some point, planned or forced).

According to Ovrkill, hereís my Ďpunyí motor (hey Brent!). All the work was done at QMP Racing in Chatsworth, CA. Iíve known Brad and Mikey for a loooong time and consider them friends. These guys really know their stuff and everything is done in house. On any given week youíll see small blocks, big blocks, turbo/blower builds, a Lambo rebuild or one of those Sonny-whats-his-names 800 cu alum motors! That thing is huge BTWÖ

I started with a stock GM LS7 crate motor. Block was CNC blueprinted, diamond honed, decked, align honed, Cam tunnel bored. We balanced the factory forged crank and added Crower billet steel connecting rods, ROSS custom pistons and pins, and a set of Total Seal custom rings. ARP main bearing studs hold it all together. Iíve got a 13 lb Fidanza aluminum flywheel and a McLeod RST clamp Iíll throw on when the time comes.

Heads were fully prepped w CNC port to breathe 390 cfm @ .0600. Milled and given their competition valve job. We kept the Titanium valves and added Manley Titanium spring cups , retainers, pushrods and polished valve springs. CHE bushed rockers help delete those pesky needle bearings. We also used some of those new Comp short throw lifters (tray type) to see if they truly help the motor build revs faster and control any valve float.

Tieing the two together is a Comp bump stick. 235/244, 630 lift w a 113+2 LSA. Brad cam doctored it as he always does and this is the formula for my intended use.

For oiling Iím using an LS9 pump, Avaid pan baffle, Peterson baffled tank and breather. These cars donít quite pull like race prepped Vetts so I think I should be good.

Up top Iíve got a Mamo ported factory intake, Fast rails and a BER ported TB. We threw a set of Fast flow matched injectors pumping 65 psi just in case I decide to add some cubes or something later on down the road.

Here's some pics...

Congratulations on you new engine.

I have three immediate items that I hope you will consider before you finish the assembly of the engine:

1) Send your pistons to Andy Suman at Line2LineCoatings.com along with your finished bore diameter, and have him coat the skirts.

2) Order a set of Smith Brothers oil flow restricting 3/8-inch pushrods.

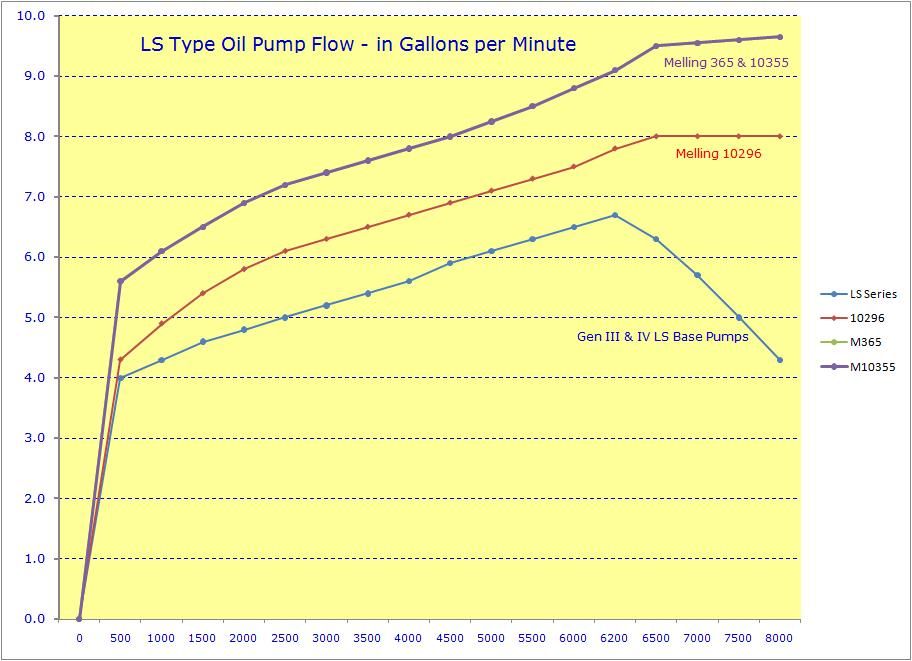

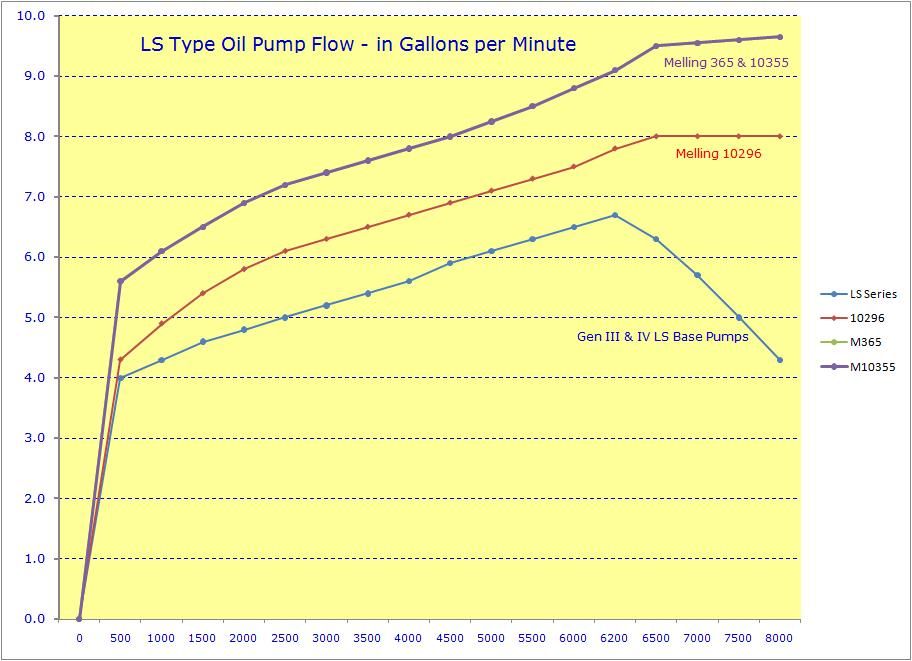

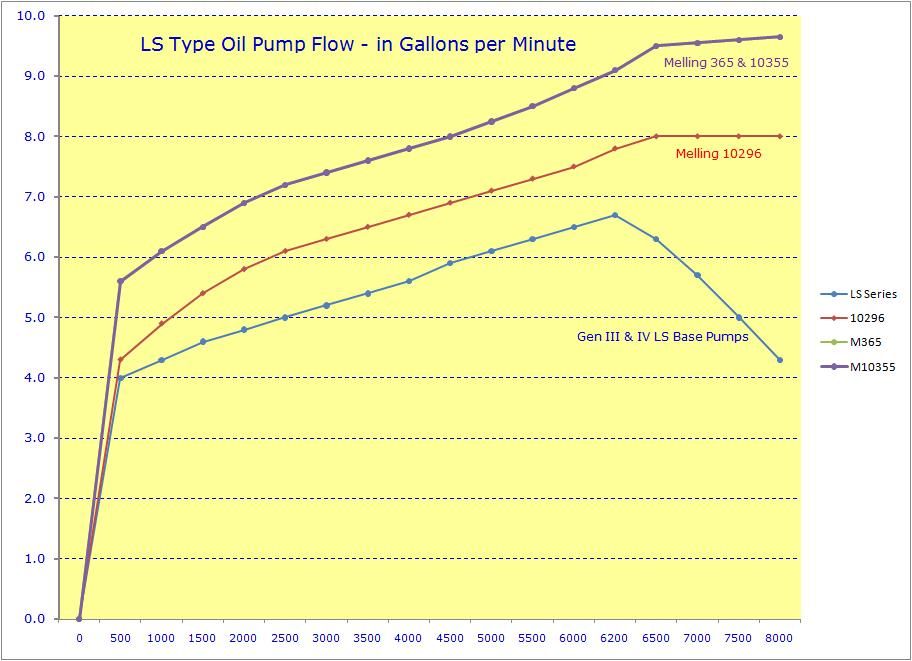

3) Replace your LS9 oil pump with a Melling 10355 oil pump.

Good luck with your new engine.

#11

Congratulations on you new engine.

I have three immediate items that I hope you will consider before you finish the assembly of the engine:

1) Send your pistons to Andy Suman at Line2LineCoatings.com along with your finished bore diameter, and have him coat the skirts.

2) Order a set of Smith Brothers oil flow restricting 3/8-inch pushrods.

3) Replace your LS9 oil pump with a Melling 10355 oil pump.

Good luck with your new engine.

I have three immediate items that I hope you will consider before you finish the assembly of the engine:

1) Send your pistons to Andy Suman at Line2LineCoatings.com along with your finished bore diameter, and have him coat the skirts.

2) Order a set of Smith Brothers oil flow restricting 3/8-inch pushrods.

3) Replace your LS9 oil pump with a Melling 10355 oil pump.

Good luck with your new engine.

#12

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

#13

^^ Pumba much respect as I think you're a smart guy. But...

* The engine is assembled and I'm not tearing it down to coat the skirts. VERY good suggestion though and something I talked about at the beginning of the build.

* I'm using Manley Pushrods. Prob could've done better but I'm ok w a good brand. I plan to work w the builder to ensure the motor is acting as it should.

* I'm running a modified factory style dry sump. Spoke to Aviad and Katech before I went this route for my intended use. The LS9 scavenges 30% better than the LS7 style.

I'm the first to admit I could've spent more research time on this build, but I think we did ok. This motor will see a phase two as part of it's care and feeding...

Sunday driver + events. Thx for the props!

* The engine is assembled and I'm not tearing it down to coat the skirts. VERY good suggestion though and something I talked about at the beginning of the build.

* I'm using Manley Pushrods. Prob could've done better but I'm ok w a good brand. I plan to work w the builder to ensure the motor is acting as it should.

* I'm running a modified factory style dry sump. Spoke to Aviad and Katech before I went this route for my intended use. The LS9 scavenges 30% better than the LS7 style.

I'm the first to admit I could've spent more research time on this build, but I think we did ok. This motor will see a phase two as part of it's care and feeding...

Sunday driver + events. Thx for the props!

#14

Quick question - what do you guys think of the Comp short throw lifters? I got the tray type and don't expect to rev the motor past 7200 (right). According to Comp and the builder, these lifters help reduce valve float and make the motor rev faster, kinda like a soild roller. Any opinions on that?

#15

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

Quick question - what do you guys think of the Comp short throw lifters? I got the tray type and don't expect to rev the motor past 7200 (right). According to Comp and the builder, these lifters help reduce valve float and make the motor rev faster, kinda like a soild roller. Any opinions on that?

The COMP short-throw hydraulic roller lifters are a very good item:

But, you need an adjustable valve train in order to get the preload set correctly.

You have C.H.E. trunions in stock rockers, so you would need to adjust preload via pushrod length. Remember if you decide to use them that your block grows 0.012 inches from 70 degrees F to 190 degrees F. That growth will affect your preload.

-

#16

TECH Fanatic

iTrader: (10)

Join Date: Mar 2011

Location: Miami gardens FL 33055

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

I used a set of the short travel hydraulic roller lifters about a year back and found the following;

The lifter where scraping the lifter bores and the filings where falling on the lifters wheels and the cam, this was rather aggressive by the way, so i removed them and deburred, and polished them, sense the set i got was ruff.

You will need a set of adjustable rocker arms, sense the max crush is .010, and that's not mush.

If the set you have are polished and deburr, you should not have any problems.

The lifter where scraping the lifter bores and the filings where falling on the lifters wheels and the cam, this was rather aggressive by the way, so i removed them and deburred, and polished them, sense the set i got was ruff.

You will need a set of adjustable rocker arms, sense the max crush is .010, and that's not mush.

If the set you have are polished and deburr, you should not have any problems.

#19

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts