LS2 New heads, new lifters, now barely starts and runs like hell. Please help

#1

Motor is a 2006 GTO LS2 with Magnusson supercharger, andTick Performance blower cam, installed in 1968 Chevelle.This has been driven in this situation for a couple of years and dyno tuned at 605hp to the wheels. It was running perfectly okay before the following mods.

Over the last couple of months I did a head swap along with a lifter replacement and new push rods from Manton. The heads were built locally with 2.020 intake valves. The lifters are Johnson short travels with the link bar.

I'm getting fuel and spark.

When I try to start, it will not start UNLESS I add heavy gas pedal input, then it comes to life. If I let off the gas, it putters out and dies. If I keep the throttle about 25% and the RPMs over 1000, it will run and sounds clean and mean. But it's rich af. All I smell is fuel and it's coming heavy out the tailpipes with heavy smoke.

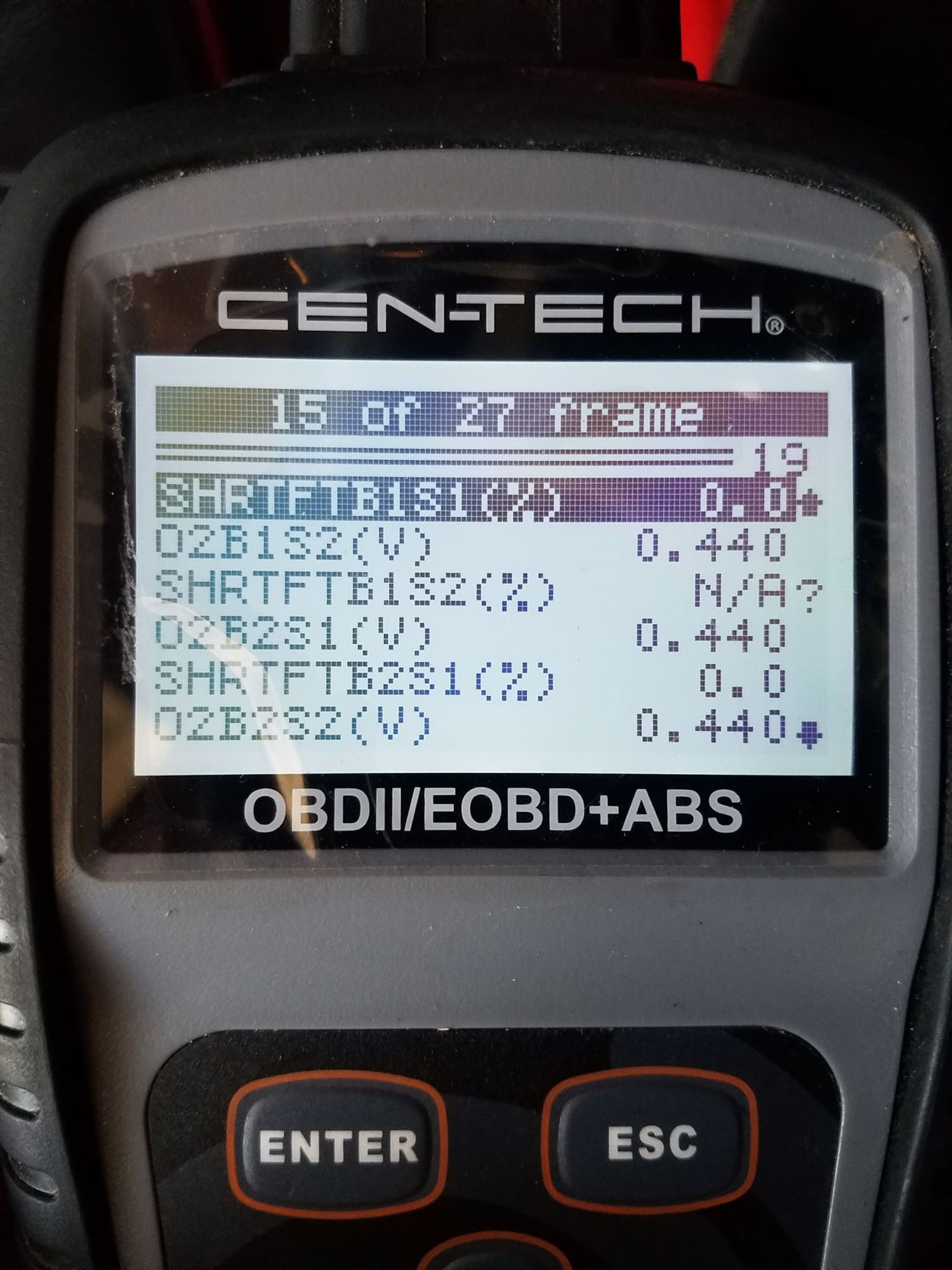

I have no CELs. It does seem indicative of a heavy vacuum leak, but I can't seem to find one. There are only so many spots for a vacuum leak. All but one vacuum port on the supercharger intake are plugged. The one in use is going to the brake booster. Someone suggested maybe a faulty O2 sensor. I'm going to try to do a sensor test tomorrow.

My first question is does it just need a new tune because of the head swap and is the afr just that messed up from the swap? If that's not normal for a head swap, I'm looking for some suggestions for troubleshooting steps. I do have a decent scanner that can pull data from sensors like long term and short term fuel trims and the like.

Thanks for the help.

Over the last couple of months I did a head swap along with a lifter replacement and new push rods from Manton. The heads were built locally with 2.020 intake valves. The lifters are Johnson short travels with the link bar.

I'm getting fuel and spark.

When I try to start, it will not start UNLESS I add heavy gas pedal input, then it comes to life. If I let off the gas, it putters out and dies. If I keep the throttle about 25% and the RPMs over 1000, it will run and sounds clean and mean. But it's rich af. All I smell is fuel and it's coming heavy out the tailpipes with heavy smoke.

I have no CELs. It does seem indicative of a heavy vacuum leak, but I can't seem to find one. There are only so many spots for a vacuum leak. All but one vacuum port on the supercharger intake are plugged. The one in use is going to the brake booster. Someone suggested maybe a faulty O2 sensor. I'm going to try to do a sensor test tomorrow.

My first question is does it just need a new tune because of the head swap and is the afr just that messed up from the swap? If that's not normal for a head swap, I'm looking for some suggestions for troubleshooting steps. I do have a decent scanner that can pull data from sensors like long term and short term fuel trims and the like.

Thanks for the help.

Last edited by leblanc1; 10-25-2019 at 11:11 AM.

#2

TECH Senior Member

Exactly what is different about the heads compared to before?

#4

TECH Senior Member

No such thing as beehive double springs. Single only.

Any porting? Bowl work?

Any porting? Bowl work?

#5

Not normal for a head swap. Something else is badly wrong.

#6

TECH Fanatic

iTrader: (23)

Sounds like it's dumping gobs of fuel into the engine. Flooring throttle during cranking clears the flood and that's why it can start.

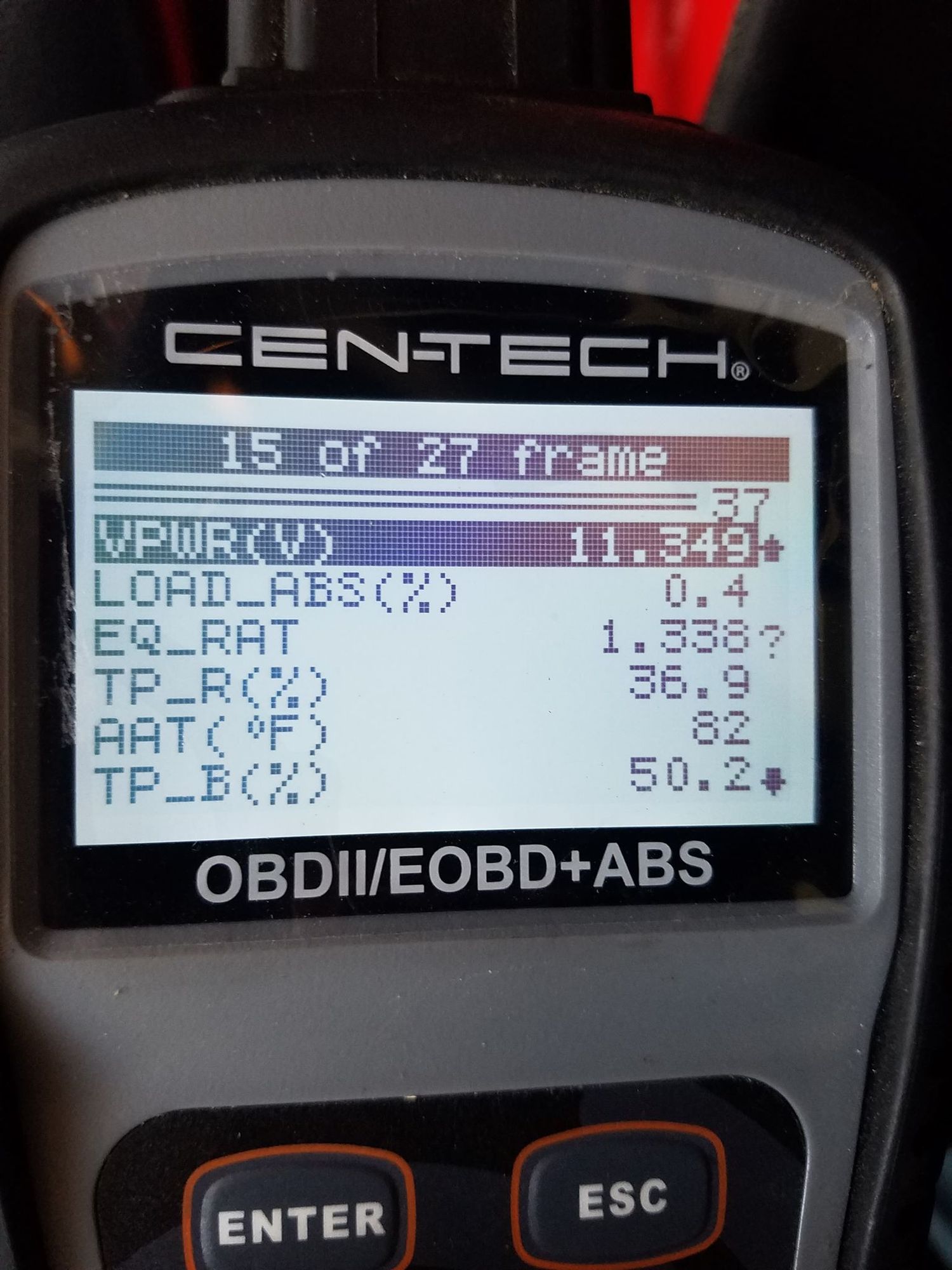

Check your data logs and look for something that's out of whack. I kind of suspect the engine thinks it's really cold (air or coolant) and it is adding a lot of fuel as if it were starting up in Arctic weather.

Check your data logs and look for something that's out of whack. I kind of suspect the engine thinks it's really cold (air or coolant) and it is adding a lot of fuel as if it were starting up in Arctic weather.

Last edited by QwkTrip; 10-24-2019 at 04:04 AM.

#7

Could the coolant temp sensor being faulty or it's plug not connecting properly cause this. That gets swapped with a head swap.

Trending Topics

#8

TECH Fanatic

iTrader: (6)

Check the plugs real good like Launch mentioned, a bad/not connected coolant temp sensor will cause it run super bad. If that checks out, you need to double check your pushrod length. If you put too long a pushrod in it, the valve will not close completely and will do exactly like what you seeing. With the short travel lifters, there is very little room for error.

BTW, you have a 2.200 intake valve on a 4.0? Bore?

BTW, you have a 2.200 intake valve on a 4.0? Bore?

#10

Sounds like it's dumping gobs of fuel into the engine. Flooring throttle during cranking clears the flood and that's why it can start.

Check your data logs and look for something that's out of whack. I kind of suspect the engine thinks it's really cold (air or coolant) and it is adding a lot of fuel as if it were starting up in Arctic weather.

Check your data logs and look for something that's out of whack. I kind of suspect the engine thinks it's really cold (air or coolant) and it is adding a lot of fuel as if it were starting up in Arctic weather.

#11

Check the plugs real good like Launch mentioned, a bad/not connected coolant temp sensor will cause it run super bad. If that checks out, you need to double check your pushrod length. If you put too long a pushrod in it, the valve will not close completely and will do exactly like what you seeing. With the short travel lifters, there is very little room for error.

BTW, you have a 2.200 intake valve on a 4.0? Bore?

BTW, you have a 2.200 intake valve on a 4.0? Bore?

Correct, the head builder I went to used 2.200 on a 4.0 bore LS2. Are there concerns with this?

#13

TECH Fanatic

iTrader: (23)

Some advice.... You have a custom engine in an old car. It is necessary that you should have tuning software and be somewhat familiar with it. I can't understand how you even got along so far.

#14

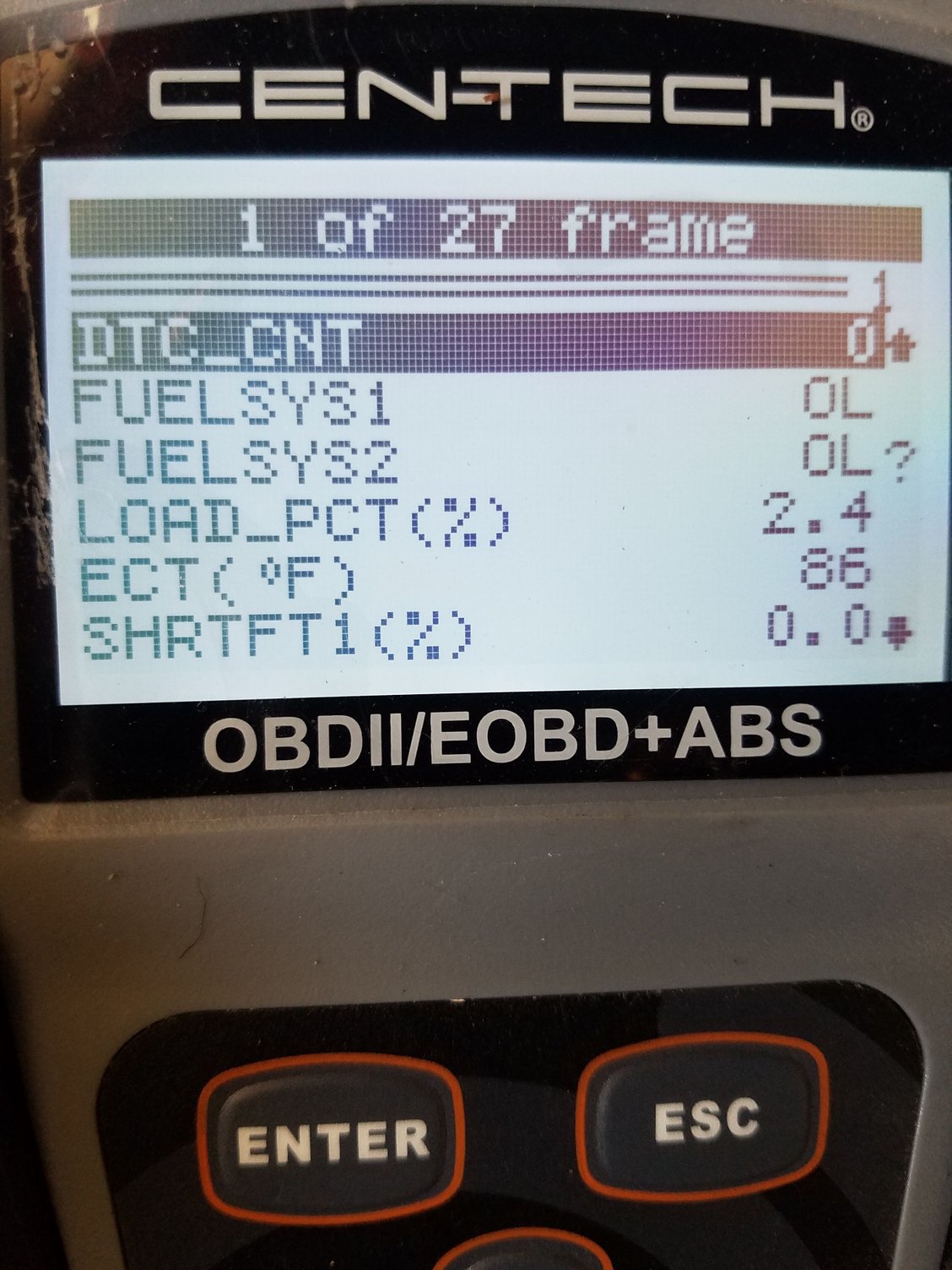

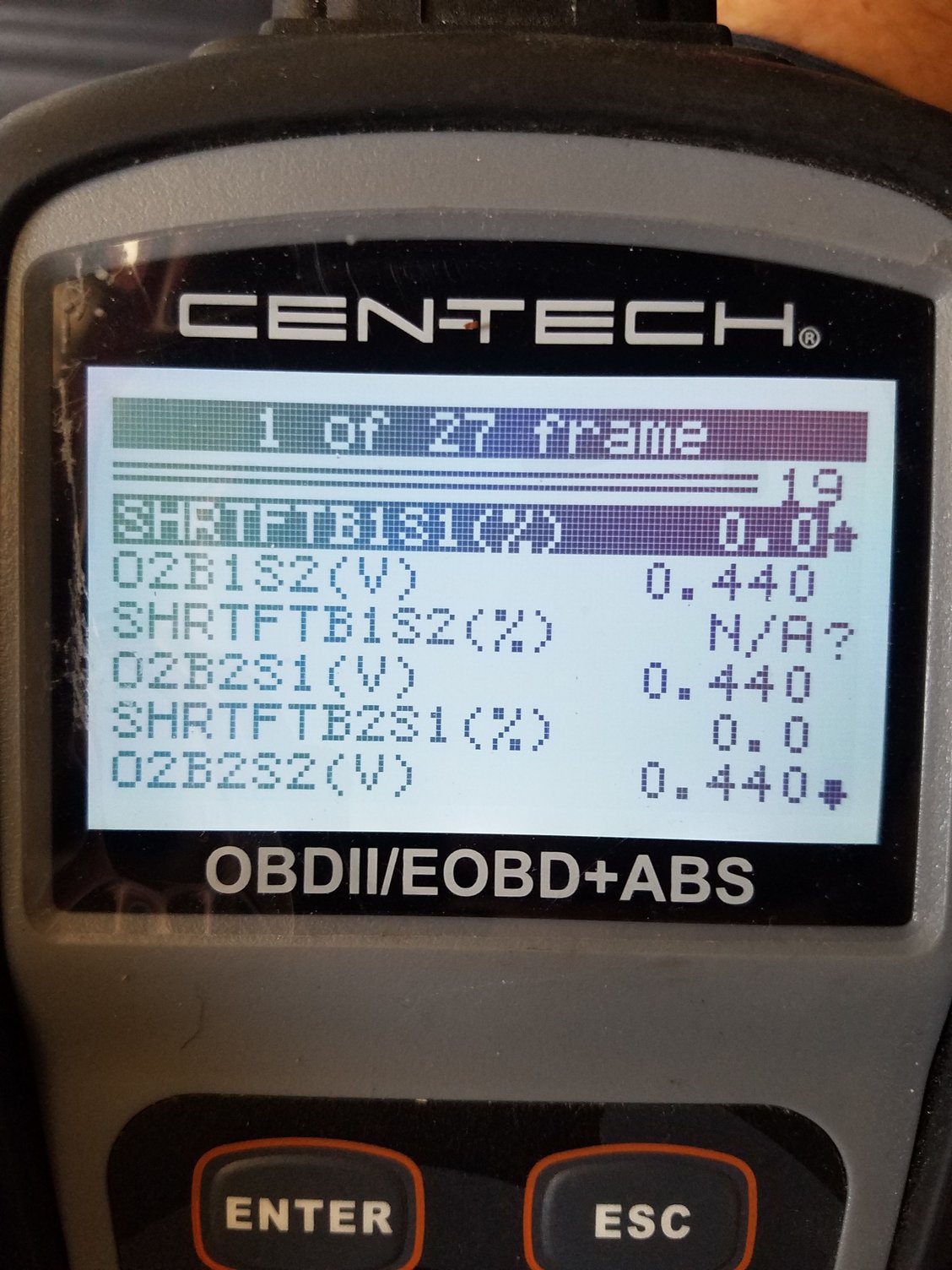

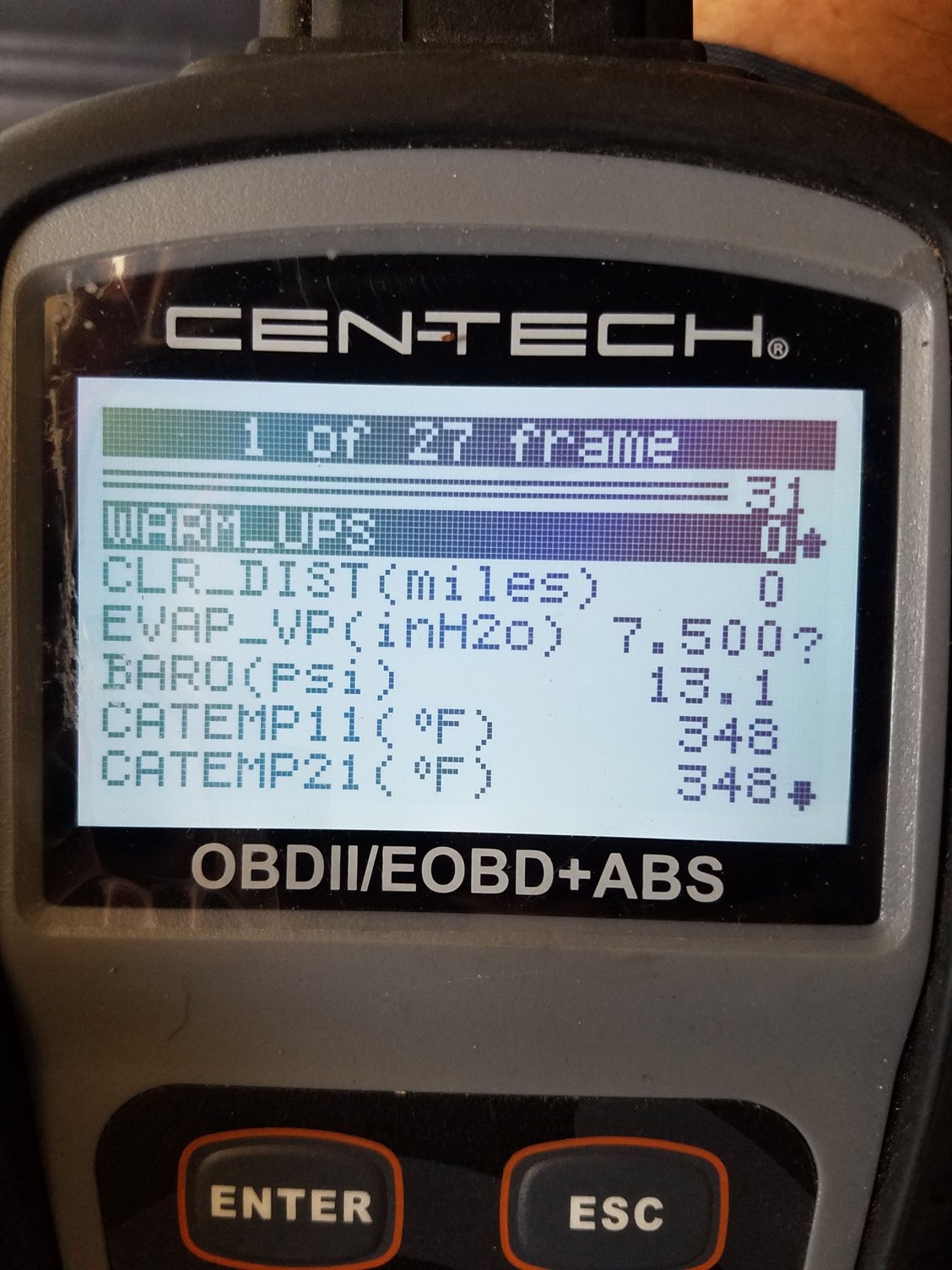

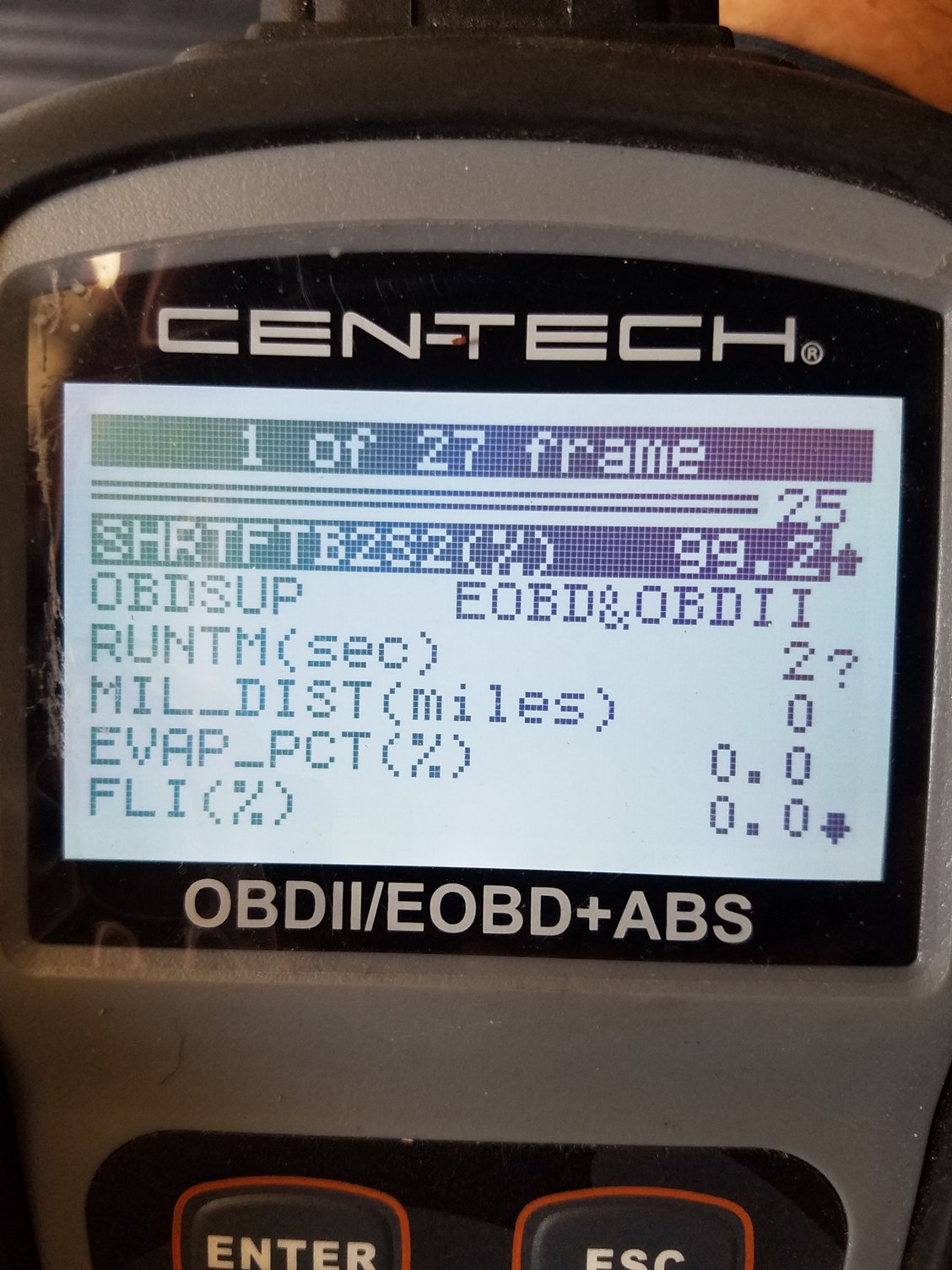

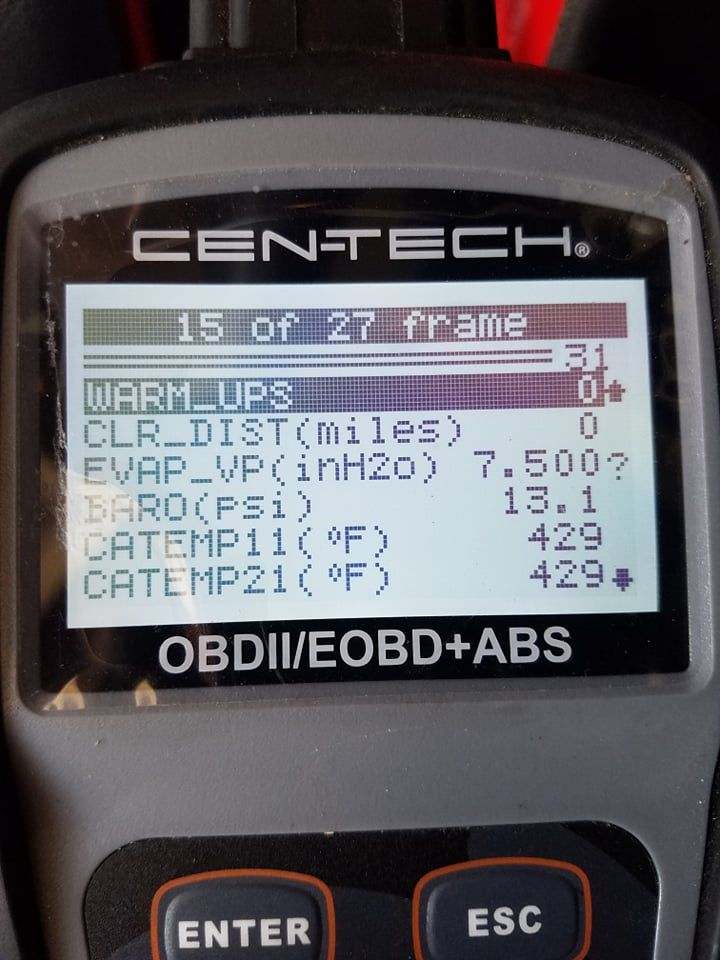

First thing I would look at is the air temp and coolant temp. Readings won't be erratic. You can even check it with a cheap OBD2 scanning tool that has a data stream function.

Some advice.... You have a custom engine in an old car. It is necessary that you should have tuning software and be somewhat familiar with it. I can't understand how you even got along so far.

Some advice.... You have a custom engine in an old car. It is necessary that you should have tuning software and be somewhat familiar with it. I can't understand how you even got along so far.

Great advice, no doubt. I've made it this far because of folks like you willing to help along the way. The mechanics of the whole thing is fairly easy. The tuning and data part, that's when I'd take it to a dyno tuner. But you're right, I'm thinking the next project might be the Terminator X Max. I never had the interest or need to get into HP Tuners.

#17

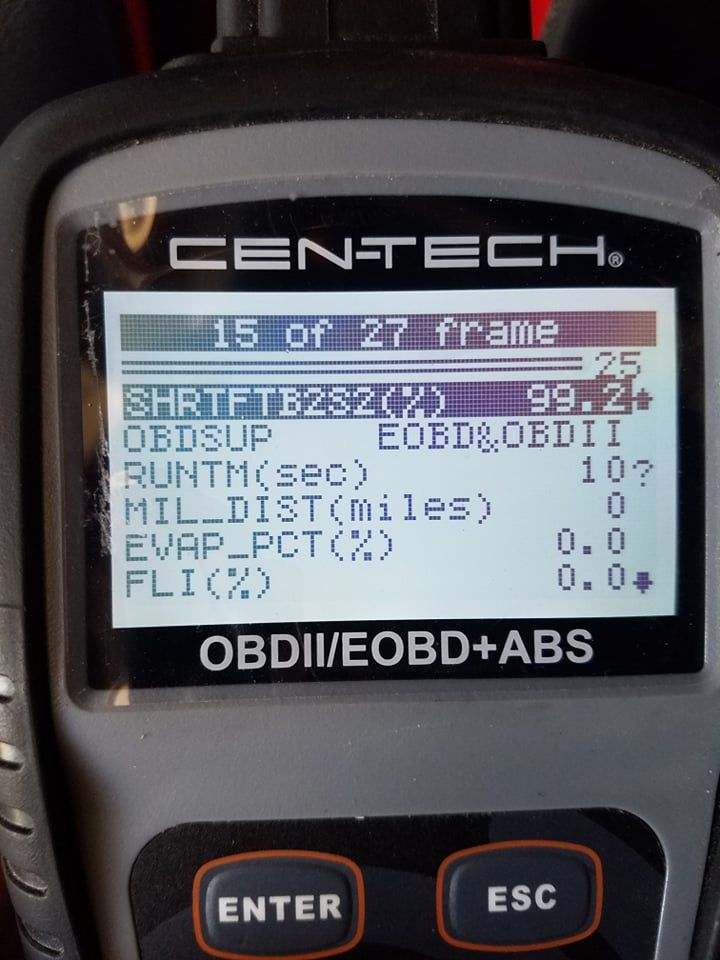

I think I'm more concerned with the short term fuel trims. 99%....O2 sensor is telling the computer it's mega lean and needs more fuel. Most will say "vacuum leak"....I get that. I'm just not seeing where it would be at the moment. This setup is quite simple. There's no MAF (speed density tuned), there's no VATS or emissions.