My winter work thread. 95 TA, lots of pics!

#81

TECH Fanatic

iTrader: (2)

Join Date: Aug 2006

Location: Bryant, AR

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

home made torque arm? I really hope you dont spend all this time and money to skimp on the important areas of the car. It all looks great with the twin turbo's and whatnot, but why not buy some professionally made turbo headers? they just look kinda shabby, i dont wanna bring you down, i am just worried about exhaust flow, i think you'll experience a lot of turbo lag and torque loss because the exhaust isnt being directed to the turbo's very efficiently. I hope everything works out though man!

#82

Tell me why my stuff won't be as good as "professional" made stuff? A good weld is a good weld and mild steel is mild steel.

Show me some "professional" Lt1 twin turbo headers that will work better than mine.

I could easily have bought a lot of stuff, I also could easily be many thousands of dollars more into the project then I am now.

Show me some "professional" Lt1 twin turbo headers that will work better than mine.

I could easily have bought a lot of stuff, I also could easily be many thousands of dollars more into the project then I am now.

#84

You know better than that ferg. I'm waiting till the suspension is under the car. It's all tacked other then the end piece, I may need to shorten one of the legs to get the pinion angle close, then make a shackle the right length to get the angle almost perfect then fine tune it with the Poly end.

When it's done there will be 3 or 4 notched pipes running up and down between the 2 horizontal pipes to brace it up. Then a nice coat of POR 15.

When it's done there will be 3 or 4 notched pipes running up and down between the 2 horizontal pipes to brace it up. Then a nice coat of POR 15.

#87

TECH Regular

Join Date: Feb 2006

Location: Winnipeg, Mb

Posts: 434

Likes: 0

Received 0 Likes

on

0 Posts

don't wanna make that torque arm adjustable? what about something more like this.

http://www.thunderracing.com/catalog...&vid=4&pcid=89

http://www.thunderracing.com/catalog...&vid=4&pcid=89

#90

TECH Addict

iTrader: (12)

home made torque arm? I really hope you dont spend all this time and money to skimp on the important areas of the car. It all looks great with the twin turbo's and whatnot, but why not buy some professionally made turbo headers? they just look kinda shabby, i dont wanna bring you down, i am just worried about exhaust flow, i think you'll experience a lot of turbo lag and torque loss because the exhaust isnt being directed to the turbo's very efficiently. I hope everything works out though man!

#91

The torque arm will be adjustable. I need to get the springs and shocks Im going to be using and the rear suspension back under the car before I can go any further on the torque arm. Once the suspension is in there I will make sure the TA is close to where it needs to be, I may need to shorten one of the legs a little, that's why the ends of the legs are just tacked for now. Once it's where it needs to be Ill get the pinion angle close then measure how long the shackle needs to be and make it. Final adjustments will be made by how far the bushing end it threaded into the torque arm. If I ever go with a different suspension setup I will just need to make a different length shackle.

I ran out of gas for the welder so i didn't get to finish up the other down pipe. Once it's done it is on to the manifolds.

Trying to round up all my suspension parts and get my gears setup so it will be a roller once again, then it's getting flat bedded to a guys shop I know. I'm building him an exhaust for his 68 camaro and he's spraying the paint for me.

Once it's back I should have my roll bar from wolfe (ordered the 8th) and I can put it and all my interior back in.

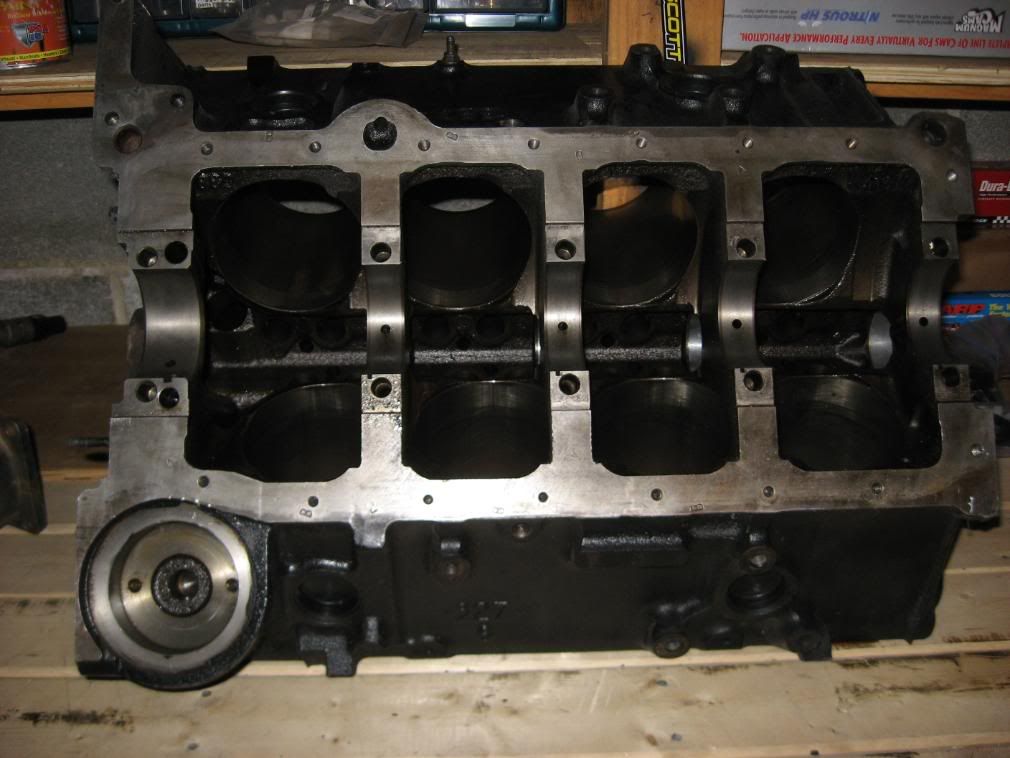

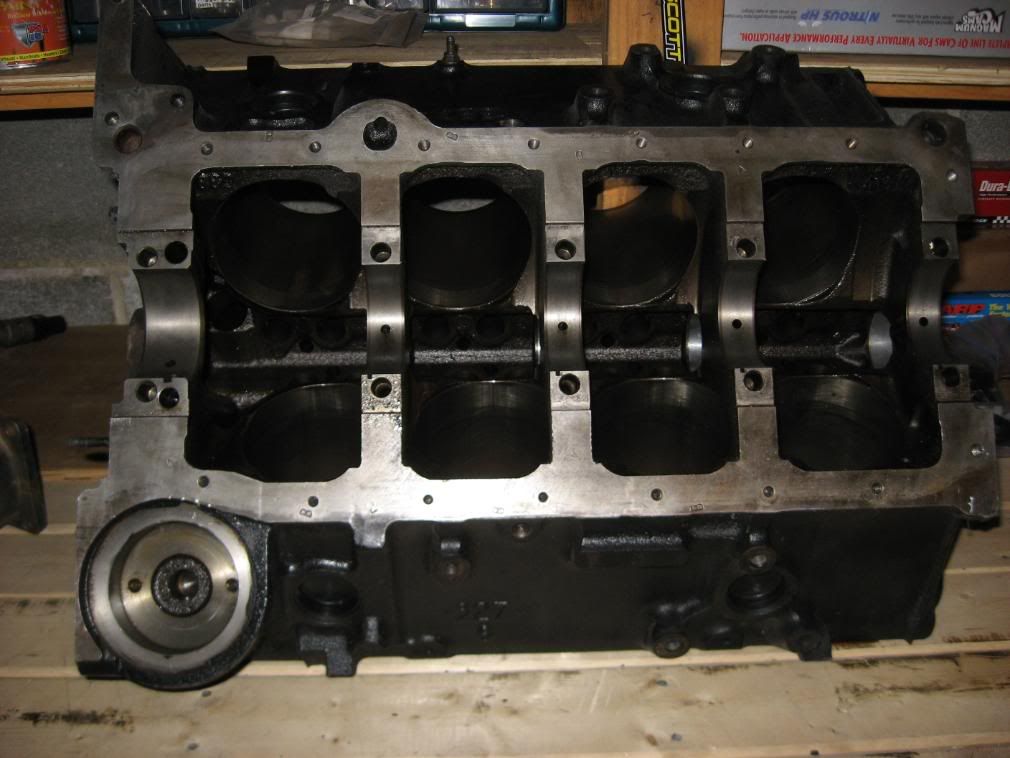

Then the final step is to get my block finished (4 bolt mains, half filled, and honed), then assemble it all and put the motor back in.

I ran out of gas for the welder so i didn't get to finish up the other down pipe. Once it's done it is on to the manifolds.

Trying to round up all my suspension parts and get my gears setup so it will be a roller once again, then it's getting flat bedded to a guys shop I know. I'm building him an exhaust for his 68 camaro and he's spraying the paint for me.

Once it's back I should have my roll bar from wolfe (ordered the 8th) and I can put it and all my interior back in.

Then the final step is to get my block finished (4 bolt mains, half filled, and honed), then assemble it all and put the motor back in.

#92

TECH Addict

iTrader: (12)

The torque arm will be adjustable. I need to get the springs and shocks Im going to be using and the rear suspension back under the car before I can go any further on the torque arm. Once the suspension is in there I will make sure the TA is close to where it needs to be, I may need to shorten one of the legs a little, that's why the ends of the legs are just tacked for now. Once it's where it needs to be Ill get the pinion angle close then measure how long the shackle needs to be and make it. Final adjustments will be made by how far the bushing end it threaded into the torque arm. If I ever go with a different suspension setup I will just need to make a different length shackle.

I ran out of gas for the welder so i didn't get to finish up the other down pipe. Once it's done it is on to the manifolds.

Trying to round up all my suspension parts and get my gears setup so it will be a roller once again, then it's getting flat bedded to a guys shop I know. I'm building him an exhaust for his 68 camaro and he's spraying the paint for me.

Once it's back I should have my roll bar from wolfe (ordered the 8th) and I can put it and all my interior back in.

Then the final step is to get my block finished (4 bolt mains, half filled, and honed), then assemble it all and put the motor back in.

I ran out of gas for the welder so i didn't get to finish up the other down pipe. Once it's done it is on to the manifolds.

Trying to round up all my suspension parts and get my gears setup so it will be a roller once again, then it's getting flat bedded to a guys shop I know. I'm building him an exhaust for his 68 camaro and he's spraying the paint for me.

Once it's back I should have my roll bar from wolfe (ordered the 8th) and I can put it and all my interior back in.

Then the final step is to get my block finished (4 bolt mains, half filled, and honed), then assemble it all and put the motor back in.

Awesome, good stuff man, love all the pics.

#93

I had to do some rearranging tonight. I've spent a small fortune on keeping the garage at bearable working temps, now with these single digit nights something had to give. I moved all the engine stuff down to the basement. Going to be doing some stuff down there since it's warm, and it put the important stuff out of the body work dust and debris.

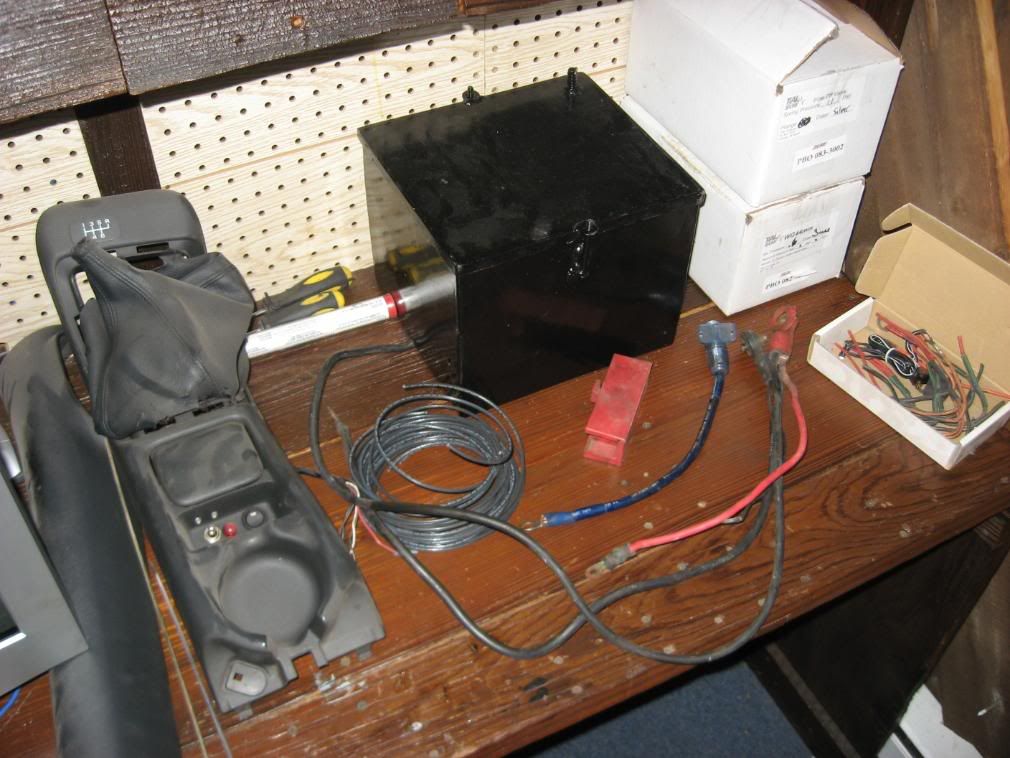

I moved more wiring stuff and such to my computer desk, my rooms getting taken over by the project to haha.

Yes I carried my block through the snow and down the steps by myself. Yes it sucked. Yes my back hurts. lol

Some new goodies came recently. Eagle 4 bolt main caps, ARP main studs, cam bearings, and freeze plugs.

All thats coming back off. Going to do a little home porting, make the CCs a little bigger, and a 3 angle valve job.

My whole interior is hibernating down there to.

I moved more wiring stuff and such to my computer desk, my rooms getting taken over by the project to haha.

Yes I carried my block through the snow and down the steps by myself. Yes it sucked. Yes my back hurts. lol

Some new goodies came recently. Eagle 4 bolt main caps, ARP main studs, cam bearings, and freeze plugs.

All thats coming back off. Going to do a little home porting, make the CCs a little bigger, and a 3 angle valve job.

My whole interior is hibernating down there to.

#94

Wastegate and BOV. Other wastegate and my intercooler will be shipped shortly.

Need to finish the battery box and rewire some switches in my center console insert and put a gauge pod on my pilar trim.

Wiring harness is coming along slowly. Keep remembering more stuff and adding more wires.

#99

TECH Fanatic

iTrader: (14)

Damn dude, you are doing a lot of projects at the same time. I don't know how you keep track of all of what you are doing but hats off to you on stellar project thus far! Subscribing just so I can see the finished product. What size turbos did you go w/? My only thing is I can't quite make out that one header w/ the open in it. What is that?

Again fuggin sweet for a DIY'er.

Again fuggin sweet for a DIY'er.

#100

Lot's of shopping, lots of good deals, doing all the work myself, can get metal for free.

I did borrow 2000 from my grandfather and I'm paying him 300 a month. That was for the waste gates/ BOV and my motor parts.

I made a lot of money selling stuff off the car that I don't need with the turbo setup and I still have more I'm trying to sell.

Figure I sold all my EFI stuff and got a carb intake for 140 shipped, and I will have about 150 in getting my carb setup. Sold my exhaust for 700 shipped and only have about $100 in my exhaust and hot parts now. Got a deal on the turbos and only paid 500 for both.

My dad bought me the roll bar on sale from wolfe for $430 for christmas, he said I needed it anyways lol.

Working at a machine shop helps to.

I probaly have A LOT less into this than most people think.