Tranny is finally on the workbench & Partially tore down *picts*

#1

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Well I finally got around to pulling the T56 out of the Camaro yesterday. It's on the bench and I'll start pulling it apart this week to see how much damage is done to it since fifth & sixth let go. I'll probally start a rebuild thread on it with lots of pictures. This will be my first manual tranny rebuild, I hope I don't mess it up! Here's what I have to work with...

Last edited by Dead Hook; 04-05-2011 at 12:43 AM.

#5

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Ya, It's a home built 8' wood bench. Not much room in the garage though... It took me two hours to pull the trans and two days to organize the garage!

Excellent! I'll take you up on that!

#6

TECH Veteran

iTrader: (12)

First valuable tip I will give, if you can pull the 5/6 cluster gear off the mainshaft by hand, the mainshaft is damaged and likely the gear. This gear is supposed to be pressed on Bubba tight and it should require a puller to pull it off.

A loose fitting 5/6 gear casues 5th and 6th gear vibes at higher speeds. I have a whole thread on this in this section. Pay very close attention to that gear when taking it apart and if there is damage, address it now.

A loose fitting 5/6 gear casues 5th and 6th gear vibes at higher speeds. I have a whole thread on this in this section. Pay very close attention to that gear when taking it apart and if there is damage, address it now.

#7

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

First valuable tip I will give, if you can pull the 5/6 cluster gear off the mainshaft by hand, the mainshaft is damaged and likely the gear. This gear is supposed to be pressed on Bubba tight and it should require a puller to pull it off.

A loose fitting 5/6 gear casues 5th and 6th gear vibes at higher speeds. I have a whole thread on this in this section. Pay very close attention to that gear when taking it apart and if there is damage, address it now.

A loose fitting 5/6 gear casues 5th and 6th gear vibes at higher speeds. I have a whole thread on this in this section. Pay very close attention to that gear when taking it apart and if there is damage, address it now.

Trending Topics

#9

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Do you have the measurements for the steel strap needed to modify a gear puller to pull the 5/6 cluster off?

#12

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Ok, so I got into the trans tonight. I didn't have much time, but I think I got to the heart of the problem. The trans has 220,000 miles on it and 5th & 6th went out.

This weekend I built a "trans table" that is ergonomically correct for a short guy like me.

Pulled the nose off and everything looked real clean

Not much but real fine shavings on the magnets. Not big particles at all.

Shift fork pads don't look well at all. Both sides were busted up.

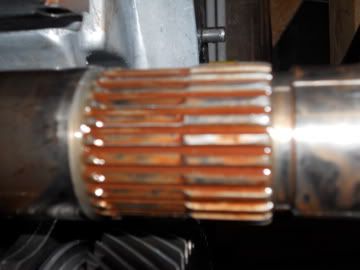

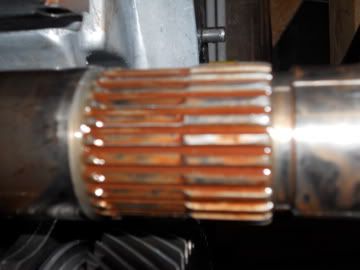

Here is what I'm assuming what is 5th or 6th gear. My grandma has better teeth.

Main shaft teeth are slightly worn...

Ya... Time for a new main shaft...

That's all I have for tonight. I'll tear down more tomorrow after work.

This weekend I built a "trans table" that is ergonomically correct for a short guy like me.

Pulled the nose off and everything looked real clean

Not much but real fine shavings on the magnets. Not big particles at all.

Shift fork pads don't look well at all. Both sides were busted up.

Here is what I'm assuming what is 5th or 6th gear. My grandma has better teeth.

Main shaft teeth are slightly worn...

Ya... Time for a new main shaft...

That's all I have for tonight. I'll tear down more tomorrow after work.

#14

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

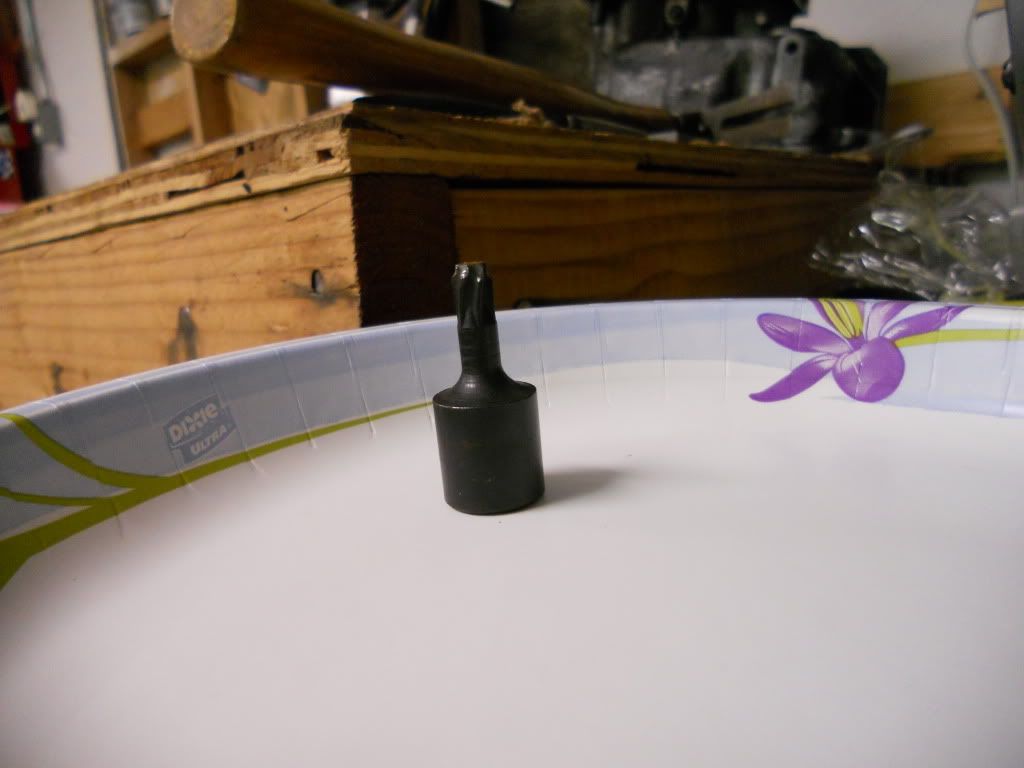

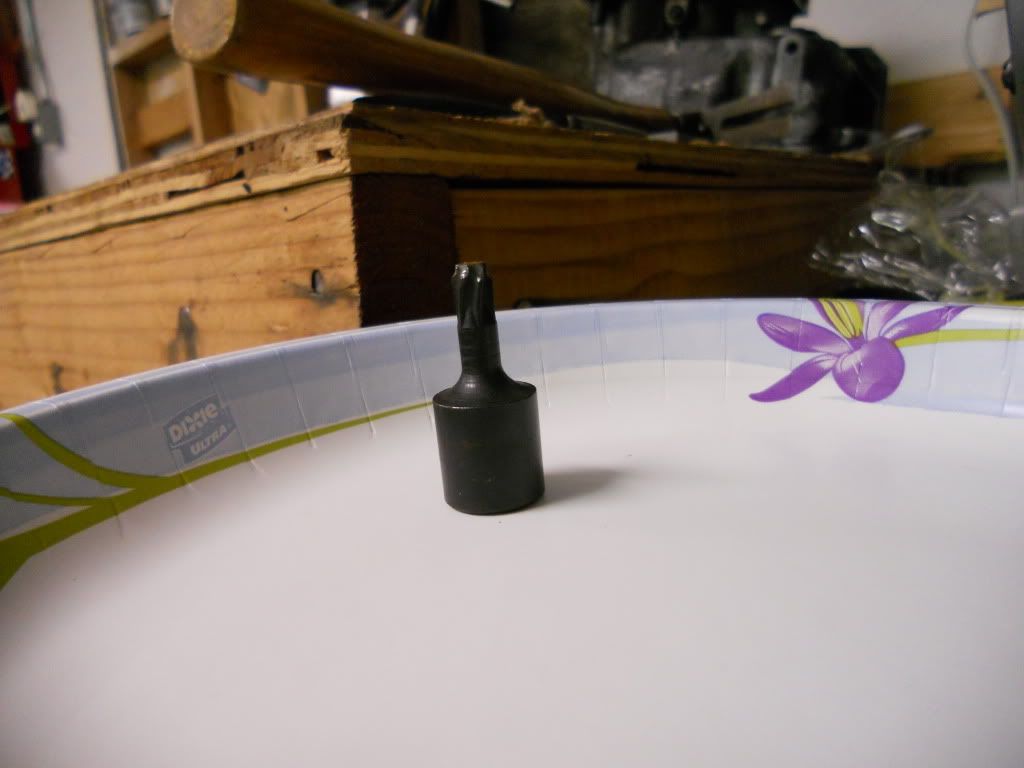

Hit a little snag tonight. I didn't realize I needed a T40 Plus not a T40. I think the screw/bolt is OK but my Torx tool has seen better days... Are SK tools good? Think I'm going to order a set from Sears.

#15

TECH Veteran

iTrader: (12)

Yep I called it and bet you did not need to make a gear puller either.

The 5/6 gear likely lost its press fit and got looser and looser till the splines just got eaten away and finally gave out. Looks like a much more severe condition of what I had. The splines on my main shaft were about a 1/3 worn away from the gear fluttering and wobbling around under load.

Yeah its a new or rebuilt main shaft and a new 5/6 driven gear in your future plus a total tear down and rebuild. While your in there and at a minimum, replace the syncro rings if they show wear on the dog teeth. Replace the blocker rings. Get a steel 3/4 shift fork and billet 3/4 keys and all new fork pads.

If you get a repaired mainshaft from TDP, the journal where the gear goes will be a few thousanths larger to ensure a tighter press fit of the 5/6 driven gear compared to a brand new shaft plus it will be cheaper. A new shaft goes for around $230 or so. The 5/6 gear goes for around $180 or so.

Once you have the housing off, take lots of pics of the puzzle like rods at the bottom that move the forks. Putting those things back together is like working a Rubiks cube until you figure it out. Also take pics of the main shaft and its components till you get familiar with the parts.

I know lots of folks have problems with those two Torx retaining bolts. I busted mine loose easily using an impact on low torque and a quality Torx bit and had no problems. Love that table by the way. I had to use saw horses and 2x4's.

I had to use saw horses and 2x4's.

The 5/6 gear likely lost its press fit and got looser and looser till the splines just got eaten away and finally gave out. Looks like a much more severe condition of what I had. The splines on my main shaft were about a 1/3 worn away from the gear fluttering and wobbling around under load.

Yeah its a new or rebuilt main shaft and a new 5/6 driven gear in your future plus a total tear down and rebuild. While your in there and at a minimum, replace the syncro rings if they show wear on the dog teeth. Replace the blocker rings. Get a steel 3/4 shift fork and billet 3/4 keys and all new fork pads.

If you get a repaired mainshaft from TDP, the journal where the gear goes will be a few thousanths larger to ensure a tighter press fit of the 5/6 driven gear compared to a brand new shaft plus it will be cheaper. A new shaft goes for around $230 or so. The 5/6 gear goes for around $180 or so.

Once you have the housing off, take lots of pics of the puzzle like rods at the bottom that move the forks. Putting those things back together is like working a Rubiks cube until you figure it out. Also take pics of the main shaft and its components till you get familiar with the parts.

I know lots of folks have problems with those two Torx retaining bolts. I busted mine loose easily using an impact on low torque and a quality Torx bit and had no problems. Love that table by the way.

I had to use saw horses and 2x4's.

I had to use saw horses and 2x4's. Last edited by wrd1972; 04-07-2011 at 03:18 AM.

#16

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

(1) 220K is about the normal milage you will see completely stripped mainshafts like that. I've seen them that bad with as low as 150K but those are normally people who lug their cars in high gear instead of learning how to down shift into a better gear for lower speed driving.

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster.

(3) If you take a medium size hammer and smack the **** out of the top of those T40 bolts before trying to remove them, it usually helps out. Using a small butane torch also helps soften up the lock tite used on those bolts from the factory.

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster.

(3) If you take a medium size hammer and smack the **** out of the top of those T40 bolts before trying to remove them, it usually helps out. Using a small butane torch also helps soften up the lock tite used on those bolts from the factory.

#17

Staging Lane

Thread Starter

Join Date: Dec 2010

Location: So Cal

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Yep I called it and bet you did not need to make a gear puller either.

The 5/6 gear likely lost its press fit and got looser and looser till the splines just got eaten away and finally gave out. Looks like a much more severe condition of what I had. The splines on my main shaft were about a 1/3 worn away from the gear fluttering and wobbling around under load.

Yeah its a new or rebuilt main shaft and a new 5/6 driven gear in your future plus a total tear down and rebuild. While your in there and at a minimum, replace the syncro rings if they show wear on the dog teeth. Replace the blocker rings. Get a steel 3/4 shift fork and billet 3/4 keys and all new fork pads.

If you get a repaired mainshaft from TDP, the journal where the gear goes will be a few thousanths larger to ensure a tighter press fit of the 5/6 driven gear compared to a brand new shaft plus it will be cheaper. A new shaft goes for around $230 or so. The 5/6 gear goes for around $180 or so.

Once you have the housing off, take lots of pics of the puzzle like rods at the bottom that move the forks. Putting those things back together is like working a Rubiks cube until you figure it out. Also take pics of the main shaft and its components till you get familiar with the parts.

I know lots of folks have problems with those two Torx retaining bolts. I busted mine loose easily using an impact on low torque and had no problems. Love that table by the way.

The 5/6 gear likely lost its press fit and got looser and looser till the splines just got eaten away and finally gave out. Looks like a much more severe condition of what I had. The splines on my main shaft were about a 1/3 worn away from the gear fluttering and wobbling around under load.

Yeah its a new or rebuilt main shaft and a new 5/6 driven gear in your future plus a total tear down and rebuild. While your in there and at a minimum, replace the syncro rings if they show wear on the dog teeth. Replace the blocker rings. Get a steel 3/4 shift fork and billet 3/4 keys and all new fork pads.

If you get a repaired mainshaft from TDP, the journal where the gear goes will be a few thousanths larger to ensure a tighter press fit of the 5/6 driven gear compared to a brand new shaft plus it will be cheaper. A new shaft goes for around $230 or so. The 5/6 gear goes for around $180 or so.

Once you have the housing off, take lots of pics of the puzzle like rods at the bottom that move the forks. Putting those things back together is like working a Rubiks cube until you figure it out. Also take pics of the main shaft and its components till you get familiar with the parts.

I know lots of folks have problems with those two Torx retaining bolts. I busted mine loose easily using an impact on low torque and had no problems. Love that table by the way.

(1) 220K is about the normal milage you will see completely stripped mainshafts like that. I've seen them that bad with as low as 150K but those are normally people who lug their cars in high gear instead of learning how to down shift into a better gear for lower speed driving.

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster.

(3) If you take a medium size hammer and smack the **** out of the top of those T40 bolts before trying to remove them, it usually helps out. Using a small butane torch also helps soften up the lock tite used on those bolts from the factory.

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster.

(3) If you take a medium size hammer and smack the **** out of the top of those T40 bolts before trying to remove them, it usually helps out. Using a small butane torch also helps soften up the lock tite used on those bolts from the factory.

#18

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

I guess, I've never tried it before. I use a butane torch like you use to sweat pipe when heat is needed. Most of the a few pops with a 2lb ball peen hammer before trying to remove it does the trick.

#19

TECH Veteran

iTrader: (12)

(1) 220K is about the normal milage you will see completely stripped mainshafts like that. I've seen them that bad with as low as 150K but those are normally people who lug their cars in high gear instead of learning how to down shift into a better gear for lower speed driving.

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster

(2) That mainshaft is junk, TDP can build up the machined area but can't replace the splines stripped away. Buy a new mainshaft and 5-6 cluster

Yes his main shaft is useless junk. The repaired shaft I got from TDP measured .0025" larger than the journal on a new shaft. That absolutely will ensure that the 5/6 gear will fit much more tight than it would on the new shaft. Also the repaired shaft I received had no wear to the splines at all so this route was much cheaper than going with a new shaft plus I have confidence the 5/6 will remain tighter down the road.

The repaired shaft was only $80.00

#20

TECH Addict

iTrader: (4)

On the two guide bolts;

Torx Plus 40 is what I use; Allen Brand

Tap the socket into the bolt with a hammer. But not so much that you crack the head of the torx bolt.

You'll then need to hold the socket firmly into the bolt head as you unthread it, else it will walk it's way out.

I like my SK ratchets and sockets but I wouldn't necessarily go to them for Torx stuff over anybody else. (I have their rail w/ T5? - T60)

Someone makes new guide bolts with regular hex heads but I can't think of who right now. Pretty easy to weld a nut on or turn down a new bolt.

Torx Plus 40 is what I use; Allen Brand

Tap the socket into the bolt with a hammer. But not so much that you crack the head of the torx bolt.

You'll then need to hold the socket firmly into the bolt head as you unthread it, else it will walk it's way out.

I like my SK ratchets and sockets but I wouldn't necessarily go to them for Torx stuff over anybody else. (I have their rail w/ T5? - T60)

Someone makes new guide bolts with regular hex heads but I can't think of who right now. Pretty easy to weld a nut on or turn down a new bolt.

Last edited by jmd; 04-06-2011 at 08:30 PM.