True tale of the Sachs NFW1050 swap flywheel

#1

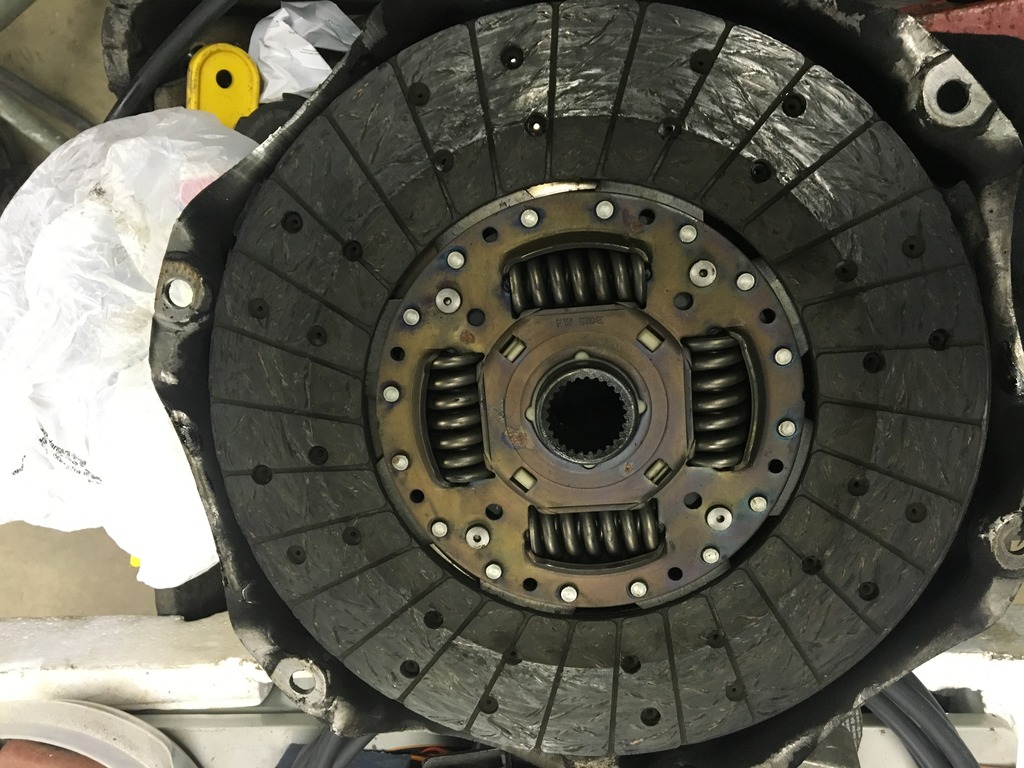

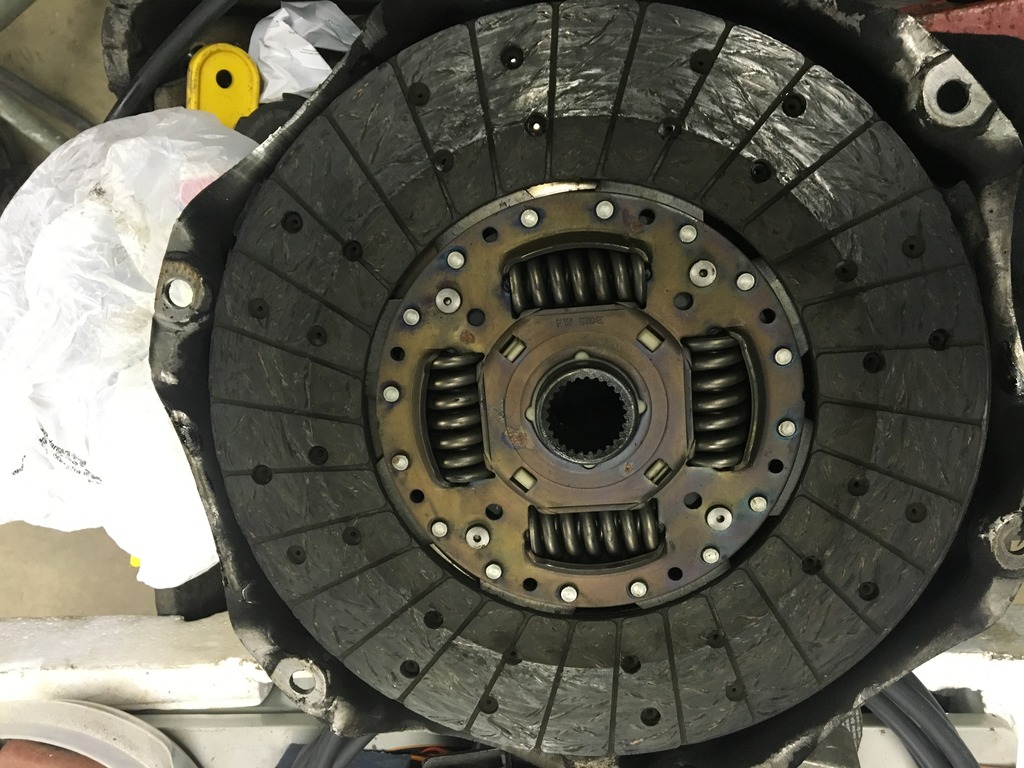

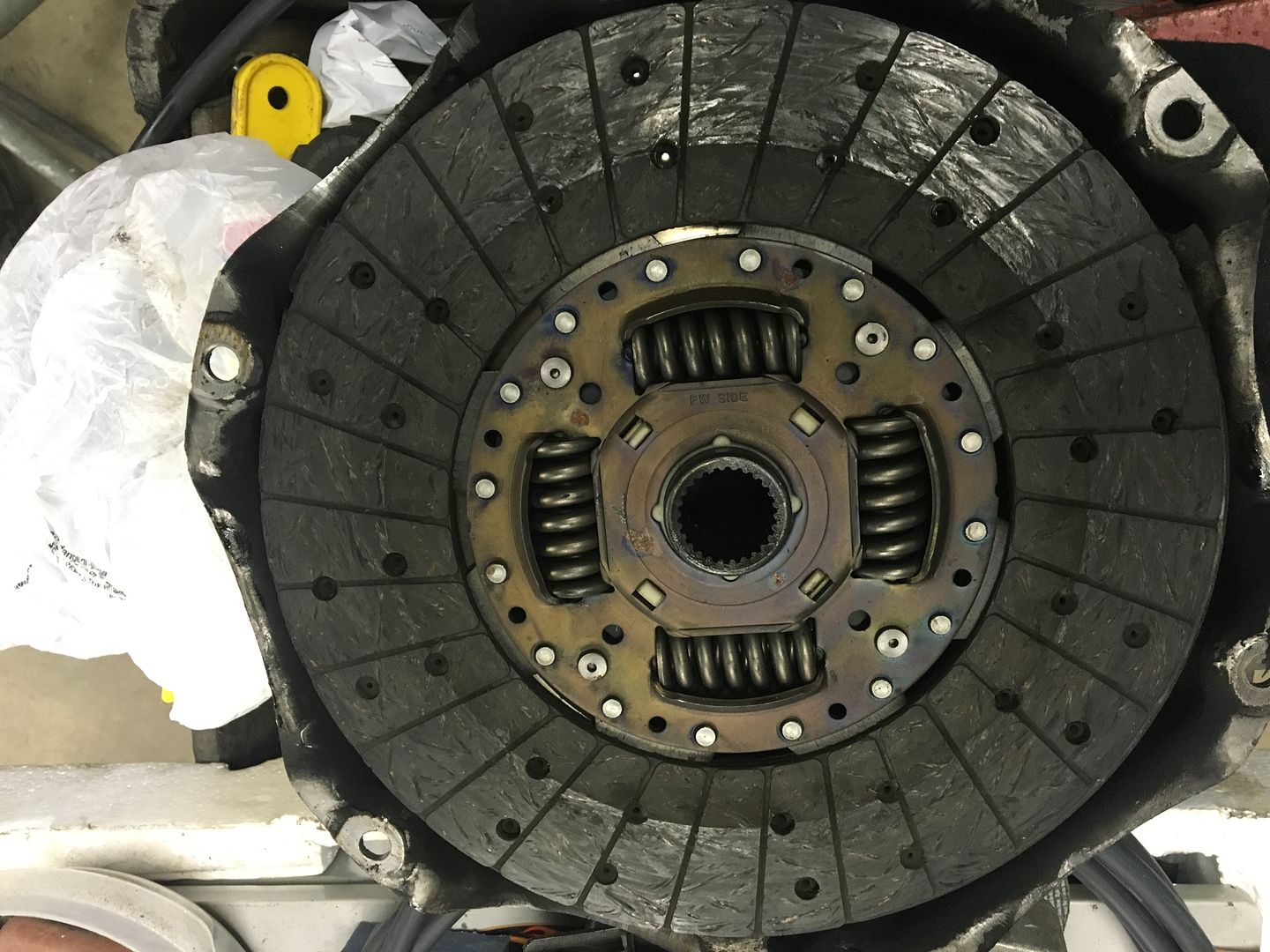

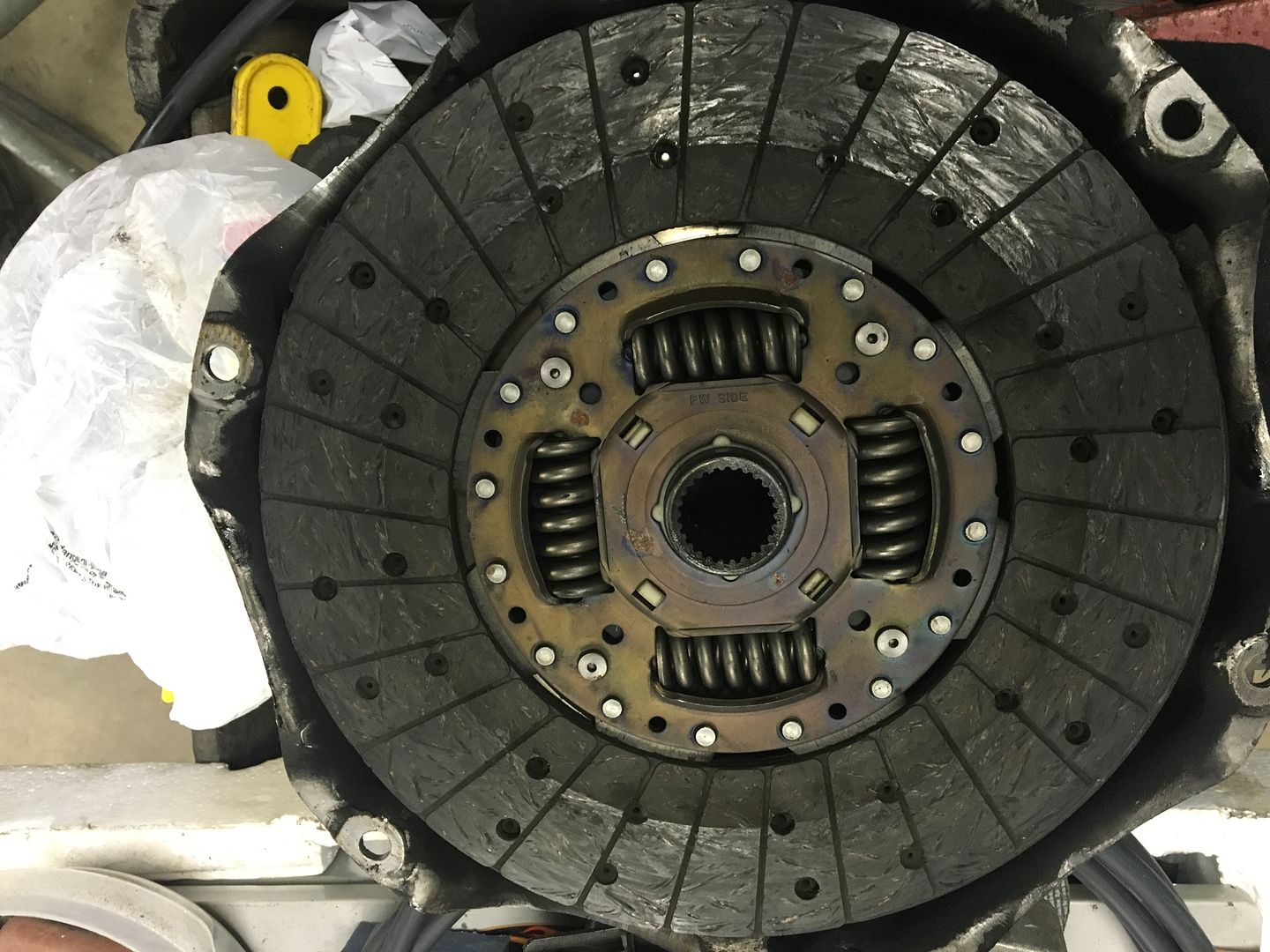

So I am in the process of putting a 76mm turbo on my 81 Camaro with L33/old school 4 speed swap so naturally I am upgrading various drivetrain components to handle to the new power...one of the major upgrades was changing out my $100 Autozone clutch that was on the car in NA trim when the car was making an estimated 350 crank HP...

I was using an 11" big block clutch along with popular Sachs NFW1050 swap flywheel (off the fairly rare manual equipped 6.0 trucks) to account for the 0.400" setback of the LS crank flange when using an old school 4/5 speed...upon disassembling the clutch and flywheel it looks like I was only using 3.5" of the 4.25" (66%) contact area of the clutch disk...clutch pictures has approximately 1000 miles on it max...I figured I would put the info out for people doing this swap so they know what the are really going to be working with clamp wise with clutch...I am starting to think I should have bought the swap bellhousing in order to use standard LS clutch kits, but you win some you lose some...my turbo engine is more than likely going to destroy my Borg Warner Super T10 4 speed anyway so I think I will buy the new bellhousing when I upgrade to a TKO 600 lol

I was using an 11" big block clutch along with popular Sachs NFW1050 swap flywheel (off the fairly rare manual equipped 6.0 trucks) to account for the 0.400" setback of the LS crank flange when using an old school 4/5 speed...upon disassembling the clutch and flywheel it looks like I was only using 3.5" of the 4.25" (66%) contact area of the clutch disk...clutch pictures has approximately 1000 miles on it max...I figured I would put the info out for people doing this swap so they know what the are really going to be working with clamp wise with clutch...I am starting to think I should have bought the swap bellhousing in order to use standard LS clutch kits, but you win some you lose some...my turbo engine is more than likely going to destroy my Borg Warner Super T10 4 speed anyway so I think I will buy the new bellhousing when I upgrade to a TKO 600 lol

#2

TECH Junkie

iTrader: (1)

See posts 42 and 161 of this thread.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

#4

TECH Senior Member

iTrader: (7)

See posts 42 and 161 of this thread.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

Andrew

#5

LS1Tech Premium Sponsor

iTrader: (40)

So I am in the process of putting a 76mm turbo on my 81 Camaro with L33/old school 4 speed swap so naturally I am upgrading various drivetrain components to handle to the new power...one of the major upgrades was changing out my $100 Autozone clutch that was on the car in NA trim when the car was making an estimated 350 crank HP...

I was using an 11" big block clutch along with popular Sachs NFW1050 swap flywheel (off the fairly rare manual equipped 6.0 trucks) to account for the 0.400" setback of the LS crank flange when using an old school 4/5 speed...upon disassembling the clutch and flywheel it looks like I was only using 3.5" of the 4.25" (66%) contact area of the clutch disk...clutch pictures has approximately 1000 miles on it max...I figured I would put the info out for people doing this swap so they know what the are really going to be working with clamp wise with clutch...I am starting to think I should have bought the swap bellhousing in order to use standard LS clutch kits, but you win some you lose some...my turbo engine is more than likely going to destroy my Borg Warner Super T10 4 speed anyway so I think I will buy the new bellhousing when I upgrade to a TKO 600 lol

I was using an 11" big block clutch along with popular Sachs NFW1050 swap flywheel (off the fairly rare manual equipped 6.0 trucks) to account for the 0.400" setback of the LS crank flange when using an old school 4/5 speed...upon disassembling the clutch and flywheel it looks like I was only using 3.5" of the 4.25" (66%) contact area of the clutch disk...clutch pictures has approximately 1000 miles on it max...I figured I would put the info out for people doing this swap so they know what the are really going to be working with clamp wise with clutch...I am starting to think I should have bought the swap bellhousing in order to use standard LS clutch kits, but you win some you lose some...my turbo engine is more than likely going to destroy my Borg Warner Super T10 4 speed anyway so I think I will buy the new bellhousing when I upgrade to a TKO 600 lol

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

#6

TECH Addict

iTrader: (4)

Use a straight edge and check the surface of the flywheel. I have had several "parts store" flywheels that have been machined with a dish in them causing this exact thing. I simply had the flywheel turned true and flat to regain full surface contact area. I had this same setup behind a 5.3 mating to a Muncie HM290 in a 68 C10. Had the same issue with that flywheel. After machining flat, it had a full even contact patch

To be clear for others, his mismatch of pressure plate / disc. will not be corrected by flywheel machining correction.

#7

See posts 42 and 161 of this thread.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

https://ls1tech.com/forums/conversio...-ls-motor.html

If you're using a 26 spline Muncie/T10, there's no reason you cant use an LS7 flywheel/clutch. plenty of grip with that.

Not sure if i mentioned in my OP but i am using a mechanical clutch linkage, not sure if that would jive with the ls7 deal or not even though i don't see why not...i was under the impression that my only options were to use the Sachs flywheel to make up the 0.400" difference (because of early 6.0" crank) when using an old school trans, or buy the expensive McLeod swap flywheel and then i could use a regular ls7 clutch

Last edited by wildcamaro; 09-14-2016 at 12:31 PM.

Trending Topics

#8

TECH Junkie

iTrader: (1)

Mechanical linkage is not a problem. I've run them on both the F body LS1flywheel clutch and the Sachs flywheel.

The 0.4" distance doesn't seem to be an issue with anyone. Just need to compensate with a longer throwout bearing.

Not sure what issues you would run into if you're talking about the 99-00 iron head long crank 6.0. I don't think that crank was ever intended to be used with manual trans.

The 0.4" distance doesn't seem to be an issue with anyone. Just need to compensate with a longer throwout bearing.

Not sure what issues you would run into if you're talking about the 99-00 iron head long crank 6.0. I don't think that crank was ever intended to be used with manual trans.