Oil Pump Question

#1

I used a Schumann’s LSPROXV oil pump with modified pickup and two bolt pickup tube flange with gasket on my NA LS454 In the beginning it hot idled at 50 psi and would hit 100psi when on the 2step but not go above 60 running up to 7800 rpm. I attributed this to the vacuum pump pulling the oil pressure down so I lowered vacuum to 6” but oil pressure didn’t change. I continued driving/racing the car and after 3500 miles and 150-200 1/4 mile runs, hot idle oil pressure was 20lb and never went over 60 psi at any rpm according to data logs.

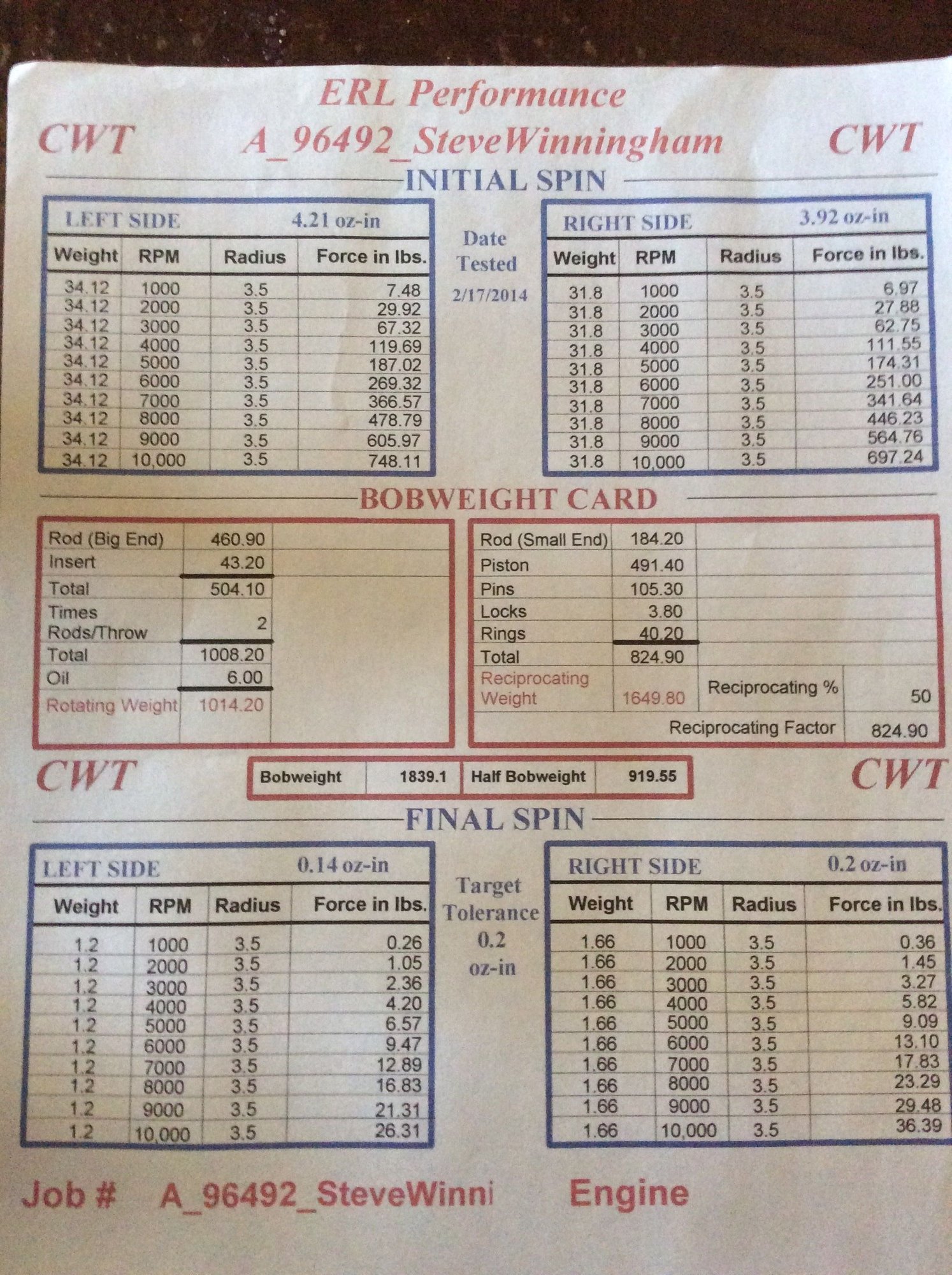

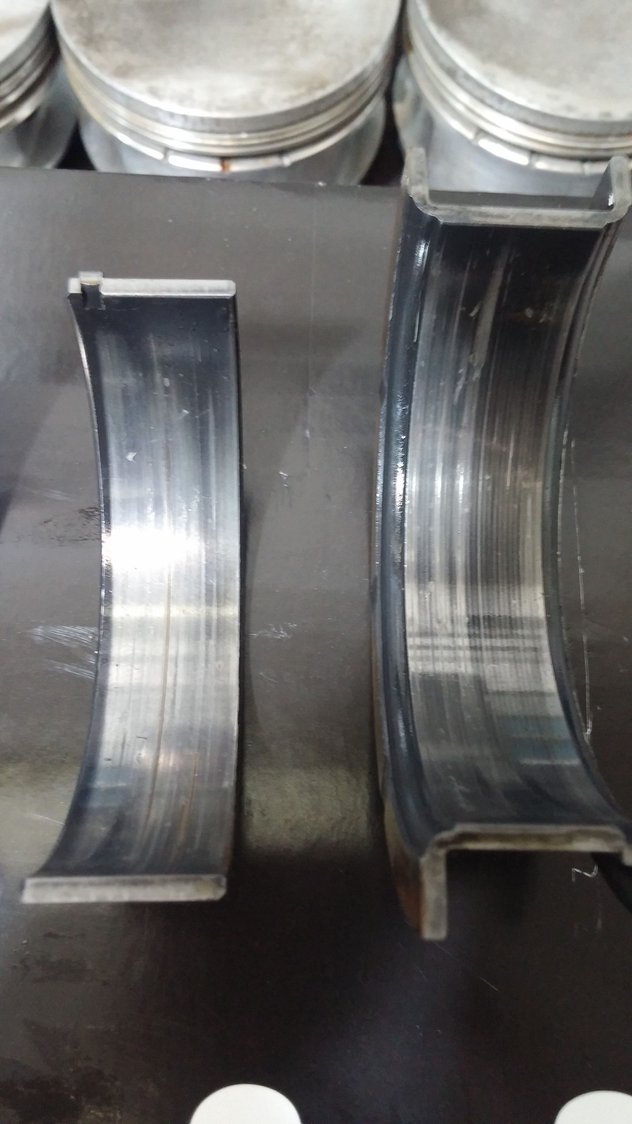

When we tore the motor down, discovered the #2 and #4 main bearings were worn pretty good (possibly from poor crankshaft balance from ERL and ) and thinking that caused the oil pressure issues.

Building a new motor now and wondering if I would be better off using a Melling 10355 or 10296 over the Schumann’s pump. The oil system has at least 6’ of external -10 lines to a remote oil filter mount and external cooler and the new motor will see 8000+ rpm.

When we tore the motor down, discovered the #2 and #4 main bearings were worn pretty good (possibly from poor crankshaft balance from ERL and ) and thinking that caused the oil pressure issues.

Building a new motor now and wondering if I would be better off using a Melling 10355 or 10296 over the Schumann’s pump. The oil system has at least 6’ of external -10 lines to a remote oil filter mount and external cooler and the new motor will see 8000+ rpm.

#2

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 17 Likes

on

17 Posts

Hi, my first question would be the Bob Weight Sheet ?

I have seen those who save money by adding weights to the Flywheel ?

Could you post pictures of #2 & #4 ?

Lance

I have seen those who save money by adding weights to the Flywheel ?

Could you post pictures of #2 & #4 ?

Lance

#3

LS1Tech Premium Sponsor

iTrader: (2)

You should meaure any pressure differential before and after the filter as well as oil temp amd up to the top of the block.

You would be better off with the 10296 in my opinion.

What pan are you running and what filter?

On the 10296 i would def port the inlet and short turn/outlet to make transitions easier and have less issues with temp building prematurely. ALSO add in the saccity billet oil barbell for added security. Does your remote mount have a bypass built into it also?

You would be better off with the 10296 in my opinion.

What pan are you running and what filter?

On the 10296 i would def port the inlet and short turn/outlet to make transitions easier and have less issues with temp building prematurely. ALSO add in the saccity billet oil barbell for added security. Does your remote mount have a bypass built into it also?

#4

Last edited by SSSTANG#1; 12-30-2017 at 03:43 PM.

#6

You should meaure any pressure differential before and after the filter as well as oil temp amd up to the top of the block.

You would be better off with the 10296 in my opinion.

What pan are you running and what filter?

On the 10296 i would def port the inlet and short turn/outlet to make transitions easier and have less issues with temp building prematurely. ALSO add in the saccity billet oil barbell for added security. Does your remote mount have a bypass built into it also?

You would be better off with the 10296 in my opinion.

What pan are you running and what filter?

On the 10296 i would def port the inlet and short turn/outlet to make transitions easier and have less issues with temp building prematurely. ALSO add in the saccity billet oil barbell for added security. Does your remote mount have a bypass built into it also?

The pan is a Moroso and filter is a Wix 51060R

#7

LS1Tech Premium Sponsor

iTrader: (2)

We are going to clean up and smooth the turns of the block oil gallery’s. Good idea of measuring pressure at different points. I already have a mechanical gauge and temp sensor on the remote oil filter adapter and a Holley pressure sensor on the valley cover. I have the Billet barbell going in the new motor and no, the remote mount doesn’t have a bypass.

The pan is a Moroso and filter is a Wix 51060R

The pan is a Moroso and filter is a Wix 51060R

Remember they get oil last so if it were an issue that they would be pretty trashed.

Youve gotta be careful with such high pressure you can blow the valley cover o rings if its a gen4 block. I would actually either tap and plug them or use the lingenfelter style rivets to keep any oil from short circuiting its path.

Im a fan of that anyway actually. Seen it fix a few erratic oil issues on afm deleted trucks.

Trending Topics

#8

Thrust sides were perfect.

I knew you were talking about porting the pump. I’ll probably stay with the Schumann’s pump.

I mentioned this in another thread but during a 1/4mile pass I shifted from the top of third gear to second and rpm went to 8400. I later discovered the pilot bearing had come apart and I think that is what caused the crank flex and took out the bearings.

Already had tapped the DOD towers and plugged them and will be doing new block also.

I knew you were talking about porting the pump. I’ll probably stay with the Schumann’s pump.

I mentioned this in another thread but during a 1/4mile pass I shifted from the top of third gear to second and rpm went to 8400. I later discovered the pilot bearing had come apart and I think that is what caused the crank flex and took out the bearings.

Already had tapped the DOD towers and plugged them and will be doing new block also.

#11

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 17 Likes

on

17 Posts

Hi SSS, OK 1839 BW.

Your RPM MAX = 7800 - 8400 ?

The Amount of Oil Held by the Piston Bottom (under crown) and Crankshaft/Rods could require an "Over Balance" of 2% as common ?

I also ask how your Two Step operates ?

The bearing pictures are great, with my observation as unseen in my past.

The "local guy" tech could be reported ?

Lance

Your RPM MAX = 7800 - 8400 ?

The Amount of Oil Held by the Piston Bottom (under crown) and Crankshaft/Rods could require an "Over Balance" of 2% as common ?

I also ask how your Two Step operates ?

The bearing pictures are great, with my observation as unseen in my past.

The "local guy" tech could be reported ?

Lance

#12

I meant port on the pump. How tight did you run the mains? I dont know if i saw those or not and how did rod bearings look.

Remember they get oil last so if it were an issue that they would be pretty trashed.

Youve gotta be careful with such high pressure you can blow the valley cover o rings if its a gen4 block. I would actually either tap and plug them or use the lingenfelter style rivets to keep any oil from short circuiting its path.

Im a fan of that anyway actually. Seen it fix a few erratic oil issues on afm deleted trucks.

Remember they get oil last so if it were an issue that they would be pretty trashed.

Youve gotta be careful with such high pressure you can blow the valley cover o rings if its a gen4 block. I would actually either tap and plug them or use the lingenfelter style rivets to keep any oil from short circuiting its path.

Im a fan of that anyway actually. Seen it fix a few erratic oil issues on afm deleted trucks.

#13

Hi SSS, OK 1839 BW.

Your RPM MAX = 7800 - 8400 ?

The Amount of Oil Held by the Piston Bottom (under crown) and Crankshaft/Rods could require an "Over Balance" of 2% as common ?

I also ask how your Two Step operates ?

The bearing pictures are great, with my observation as unseen in my past.

The "local guy" tech could be reported ?

Lance

Your RPM MAX = 7800 - 8400 ?

The Amount of Oil Held by the Piston Bottom (under crown) and Crankshaft/Rods could require an "Over Balance" of 2% as common ?

I also ask how your Two Step operates ?

The bearing pictures are great, with my observation as unseen in my past.

The "local guy" tech could be reported ?

Lance

RPM max, two step was set to 8k. It went to 8400 when I shifted from the top of 3rd gear to 2nd gear...Mechanical over-rev.

Holley EFI two step is set to “high only” 8000rpm

Can you explain the last two statements please?

“The bearing pictures are great, with my observation as unseen in my past.”

“The "local guy" tech could be reported ?”

Oh, the oil pan is a Moroso 21150.

#14

Last night I noticed the oil pressure on my truck (factory gauge) is at 45 cold idle and then drops to 40 when it warms up and around 50+ cruising and it has 120k miles.

#15

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 17 Likes

on

17 Posts

Hi SSS, My kind words of GOOD pictures provided, with addition of NOT Common Damage seen by LS race engine Tear Down observations.

Most of my engine inspections see Main Bearings as in NEW Condition.

YOUR "local guy" reported to you "the balance was way off."

My question related to his report ?

The Holley Rev Limiter Method is my observation of a possible cause of Bearing Damage.

My ECU retards timing first as a Soft Touch for Start Line with smooth engine operation.

Did your 8K limit sound even ?

1839 Bob Weight = "0" Balance

Lance

Most of my engine inspections see Main Bearings as in NEW Condition.

YOUR "local guy" reported to you "the balance was way off."

My question related to his report ?

The Holley Rev Limiter Method is my observation of a possible cause of Bearing Damage.

My ECU retards timing first as a Soft Touch for Start Line with smooth engine operation.

Did your 8K limit sound even ?

1839 Bob Weight = "0" Balance

Lance