Post pics of your garage / shop

#603

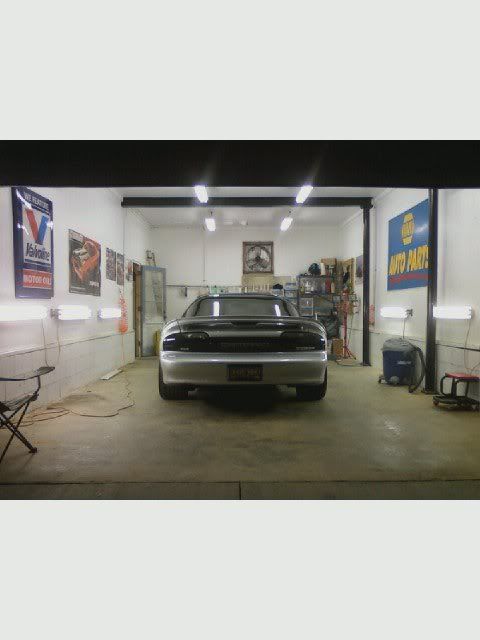

The garage has taken a long time to get here. This year has been pretty good though.

Here's a pic of the garage about a year ago...

Started getting the vapor barrier up. It's a pain getting anything done in a garage full of stuff.

Started sheeting with 1/2" plywood.

My brother getting a hand from my 3 year old...

Got all the sheeting done and caulked the joints with silicone.

Had to take a break over Christmas to pull my new motor for my '66.

My wife painted the whole garage for me. She had help from my daughters too.

As the garage sits now. Lots left to do. Finish the bench, trim doors and windows, hang posters and signs, bought all the copper last time I was home to run airlines, build shelves above the compressor room, etc...

Here's a pic of the garage about a year ago...

Started getting the vapor barrier up. It's a pain getting anything done in a garage full of stuff.

Started sheeting with 1/2" plywood.

My brother getting a hand from my 3 year old...

Got all the sheeting done and caulked the joints with silicone.

Had to take a break over Christmas to pull my new motor for my '66.

My wife painted the whole garage for me. She had help from my daughters too.

As the garage sits now. Lots left to do. Finish the bench, trim doors and windows, hang posters and signs, bought all the copper last time I was home to run airlines, build shelves above the compressor room, etc...

#605

TECH Addict

iTrader: (8)

Notch1988......save yourself the money and run the airlines with 3/4 inch PVC, schedule 40. Use regular PVC primer/clue for the joints, and it will 100% be able to support high pressure from even a 2-3 stage air compressor....I promise. I have maybe $75 in all the lines in my garage. It is $.139 per foot at Home Depot.

#606

10 Second Club

iTrader: (4)

Notch1988......save yourself the money and run the airlines with 3/4 inch PVC, schedule 40. Use regular PVC primer/clue for the joints, and it will 100% be able to support high pressure from even a 2-3 stage air compressor....I promise. I have maybe $75 in all the lines in my garage. It is $.139 per foot at Home Depot.

Pex tubing on the other hand will last a long time and will not shatter like pvc, it's probably cheaper too, and alot faster to run. It's rated to 150 psi working pressure.

#607

TECH Addict

iTrader: (8)

Yea...terrible advice...considering my dad has owned and operated one of the most successful shops in our area, for 20 years, on the same 3/4 PVC shedule 40 pipes, without a single problem. As long as you have valves to release the moisture and water, which I do, its perfectly fine and cost effective, especially for a do it yourselfer who has a shop at their house to just mess around in.

And FYI...schedule 40 PVC in 3/4 is rated a 300 psi operating pressure. As long as the joints are glued nicely, it IS fine! Just tryin to save the fella some money....people these days go way overkill for no ******* reason at all, other than to point and brag about what they have, when they really don't need it lol.

And FYI...schedule 40 PVC in 3/4 is rated a 300 psi operating pressure. As long as the joints are glued nicely, it IS fine! Just tryin to save the fella some money....people these days go way overkill for no ******* reason at all, other than to point and brag about what they have, when they really don't need it lol.

#610

UNDER PRESSURE MOD

iTrader: (19)

Yea...terrible advice...considering my dad has owned and operated one of the most successful shops in our area, for 20 years, on the same 3/4 PVC shedule 40 pipes, without a single problem. As long as you have valves to release the moisture and water, which I do, its perfectly fine and cost effective, especially for a do it yourselfer who has a shop at their house to just mess around in.

And FYI...schedule 40 PVC in 3/4 is rated a 300 psi operating pressure. As long as the joints are glued nicely, it IS fine! Just tryin to save the fella some money....people these days go way overkill for no ******* reason at all, other than to point and brag about what they have, when they really don't need it lol.

And FYI...schedule 40 PVC in 3/4 is rated a 300 psi operating pressure. As long as the joints are glued nicely, it IS fine! Just tryin to save the fella some money....people these days go way overkill for no ******* reason at all, other than to point and brag about what they have, when they really don't need it lol.

Please do yourself a favor and read this:

http://www.osha.gov/dts/hib/hib_data/hib19880520.html

Are you a polymer chemist by chance? Just asking to get a basis of where your knowlege base is.

I hope for your Dad's sake, none of any of the employees working around those pvc lines get hurt.

In a home garage, the difference between using pvc and copper or even PEX is less than $100. Is $100 worth your well being or safety? You tell me.

The problem with PVC is over time and exposure to uv rays, it becomes very brittle. Sure, it'll hold 300psi when new, but the shockwave of pressure that goes through a line when valves open and close is tough on them over time. Guess what happens to those brittle lines when something hits it by accidnet? Plastic shrapnel is what happens.

Don't be cheap, put your safety and your families safety first and either use PEX or copper lines.

#614

TECH Resident

iTrader: (17)

Please do yourself a favor and read this:

http://www.osha.gov/dts/hib/hib_data/hib19880520.html

Are you a polymer chemist by chance? Just asking to get a basis of where your knowlege base is.

I hope for your Dad's sake, none of any of the employees working around those pvc lines get hurt.

In a home garage, the difference between using pvc and copper or even PEX is less than $100. Is $100 worth your well being or safety? You tell me.

The problem with PVC is over time and exposure to uv rays, it becomes very brittle. Sure, it'll hold 300psi when new, but the shockwave of pressure that goes through a line when valves open and close is tough on them over time. Guess what happens to those brittle lines when something hits it by accidnet? Plastic shrapnel is what happens.

Don't be cheap, put your safety and your families safety first and either use PEX or copper lines.

http://www.osha.gov/dts/hib/hib_data/hib19880520.html

Are you a polymer chemist by chance? Just asking to get a basis of where your knowlege base is.

I hope for your Dad's sake, none of any of the employees working around those pvc lines get hurt.

In a home garage, the difference between using pvc and copper or even PEX is less than $100. Is $100 worth your well being or safety? You tell me.

The problem with PVC is over time and exposure to uv rays, it becomes very brittle. Sure, it'll hold 300psi when new, but the shockwave of pressure that goes through a line when valves open and close is tough on them over time. Guess what happens to those brittle lines when something hits it by accidnet? Plastic shrapnel is what happens.

Don't be cheap, put your safety and your families safety first and either use PEX or copper lines.

Look on your compressor tank - you should see a "U" or "UM" stamped into the name plate. It is there for a reason. It is basicly a statement that the compressor tank was designed and built to ASME code (Sect. VIII Div 1). Meaning it is designed so it wont blow up.

In Delaware we must register all pressure vessels (commercial not residential) and they are inspected regularly by the Division of Boiler Safety. It is a violation to plumb any airline that doesnt meet or exceed ANSI/ASME specs.

The fact is due to the compressibility of gases any rupture in a gas pressure vessel is more likey to fragment the vessel.

#615

I will be moving to a new house in a couple months and it has a very nice four stall plus garage with the back section double high for campers but i have no camper nor probably never will  So a few questions for some of you experience garage builders. I would like to put a lift in the larger stall (preferably used due to budget) and apoxy the floor. It's already insulated, and drywalled in most places and I would also like to install a bigger drain in one of the front stalls so that I can make a washbay out of that stall. So How much should I expect to pay for these things if i can install them all myself. Also what else should I have to do to my washbay stall to make it full functional for a long time?

So a few questions for some of you experience garage builders. I would like to put a lift in the larger stall (preferably used due to budget) and apoxy the floor. It's already insulated, and drywalled in most places and I would also like to install a bigger drain in one of the front stalls so that I can make a washbay out of that stall. So How much should I expect to pay for these things if i can install them all myself. Also what else should I have to do to my washbay stall to make it full functional for a long time?

So a few questions for some of you experience garage builders. I would like to put a lift in the larger stall (preferably used due to budget) and apoxy the floor. It's already insulated, and drywalled in most places and I would also like to install a bigger drain in one of the front stalls so that I can make a washbay out of that stall. So How much should I expect to pay for these things if i can install them all myself. Also what else should I have to do to my washbay stall to make it full functional for a long time?

So a few questions for some of you experience garage builders. I would like to put a lift in the larger stall (preferably used due to budget) and apoxy the floor. It's already insulated, and drywalled in most places and I would also like to install a bigger drain in one of the front stalls so that I can make a washbay out of that stall. So How much should I expect to pay for these things if i can install them all myself. Also what else should I have to do to my washbay stall to make it full functional for a long time?

#618

10 Second Club

iTrader: (10)

Speaking from personal experience, having had pvc shards slice my legs when a line exploded, I would never use pvc for plumbing air lines. You could use it and I know plenty that have but if a line let go and one of my children lost an eye or was injured I wouldn't feel justified in my savings.

If you are determined to use pvc at least make the point of connection from rigid pipe and clamp it down tightly so the pvc can't be put in a bind from the hose being pulled. Something as simple as someone stepping on or tripping over a hose can break the pvc.

If you are determined to use pvc at least make the point of connection from rigid pipe and clamp it down tightly so the pvc can't be put in a bind from the hose being pulled. Something as simple as someone stepping on or tripping over a hose can break the pvc.

#619

TECH Fanatic

iTrader: (10)

Speaking from personal experience, having had pvc shards slice my legs when a line exploded, I would never use pvc for plumbing air lines. You could use it and I know plenty that have but if a line let go and one of my children lost an eye or was injured I wouldn't feel justified in my savings.

If you are determined to use pvc at least make the point of connection from rigid pipe and clamp it down tightly so the pvc can't be put in a bind from the hose being pulled. Something as simple as someone stepping on or tripping over a hose can break the pvc.

If you are determined to use pvc at least make the point of connection from rigid pipe and clamp it down tightly so the pvc can't be put in a bind from the hose being pulled. Something as simple as someone stepping on or tripping over a hose can break the pvc.

Some of these garages make me go

thinking about all the bullshit ive gone thru doing work on my back or in nasty conditions when it would have been a breeze with the machinery some of u have available, bastards!

thinking about all the bullshit ive gone thru doing work on my back or in nasty conditions when it would have been a breeze with the machinery some of u have available, bastards!

I guess I should be thankful tho for what I do have as its much more than some of these other spaces you guys are working in.

But damn, having two lifts or even one for that matter would be ****!