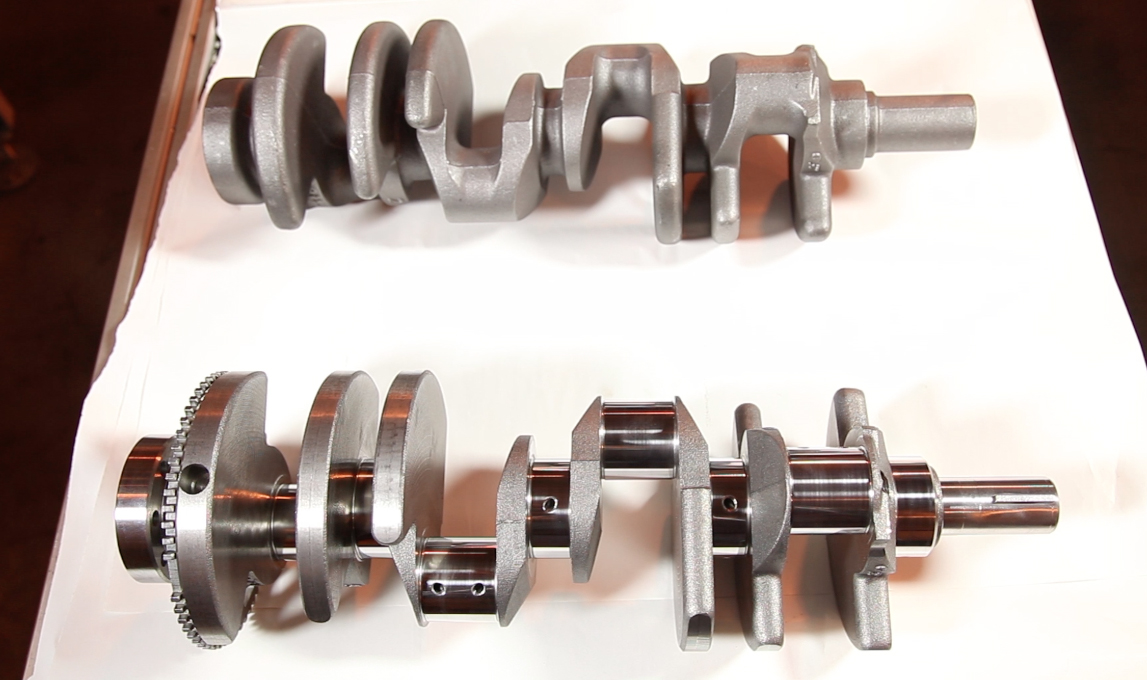

Polished to Perfection: The GM 5.3-liter EcoTec3 V8’s Crankshaft

While it takes a lot of time and effort to polish any piece of metal, there are benefits for parts that wear against each other. So, when it came time to not only make the EcoTec3 5.3-liter V8 even more efficient and wear in for the long run, GM went with the tried and true method of polishing the crankshaft journals.

“There are good reasons behind this polishing,” said Anthony Lewandowski, manufacturing engineer at Tonawanda Engine. “When a truck’s tachometer says that its engine is comfortably cruising at 3,600 RPM, that means a crankshaft is revolving 60 times each second inside its bearings on a thin coating of oil.

“Micro-polishing the crank’s journals improves this oil film’s consistency to reduce friction and improve the EcoTec3’s reliability and durability over the life of the truck.”

The tolerance of the crankshaft journals is only eight-microns between each. That’s right; the difference between each one of those journals can be no more than the width of a human red blood cell.

With such a tight tolerance that means the precision of the tooling is insane. While you might not be able to feel the minute degree differences in temperature in your house through the day, the sensors measuring the tolerance have to be taken into account, retested, and recalibrated for the 900 crankshafts produced per day at the Tonawanda Engine Plant.

You’ll find this micro-polished EcoTec3 in the Chevrolet Tahoe, Silverado, Suburban, and GMC Yukon and Sierra.