4l60e drilling spacer plate

#1

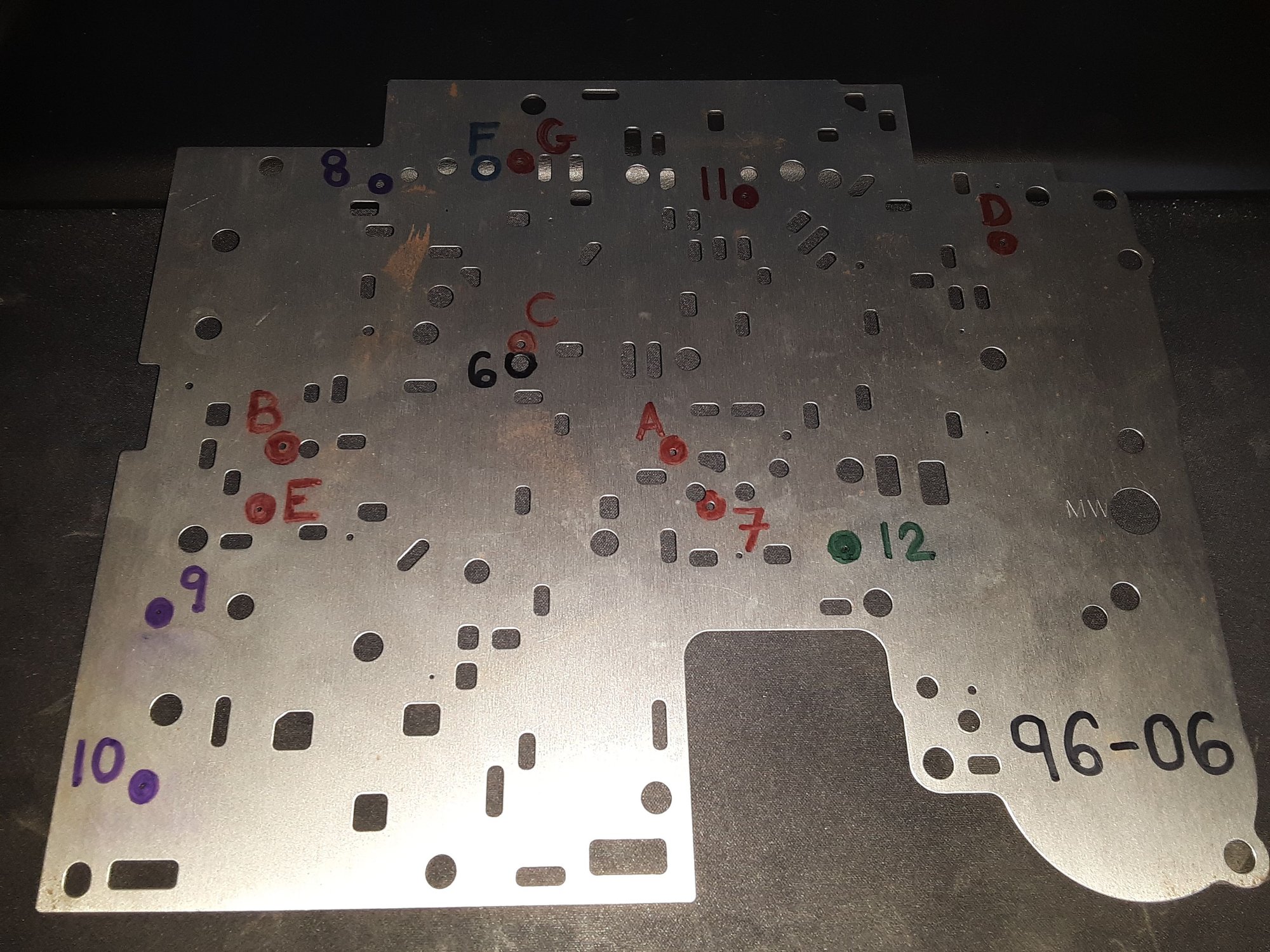

Fellas, Iím putting together a pretty stout build for a buddy of mine for his turbo truck. It has everything you can do except the sonnax 6 pinion carrier set. Iím at the point where Iím doing some drilling of spacer plate holes and I had a question. Below in the pic is what Iíve drilled it so far. The ones circled are in question to whether I should drill or not. Opinion? I chose to drill the 1-2 on the smaller side because the 1-2 hits pretty hard in my car and this guy will have a tighter converter than I have.

parts list for those interested:

sonnax billet input and output shafts

sonnax hd reaction shaft

4l79 drum with gpz 3-4 clutches

carbon wide band

billet 2-4 servo

billet pinless accumulator pistons

sealed servo pin

beast shell

sonnax had 2-3 shift valve

kolene forward steels

sonnax heavy duty over run clutch hub

.500 boost valve

hp pump spring

freshly machined pump

input drum reinforcement kit

blue molded pistons

etc etc

parts list for those interested:

sonnax billet input and output shafts

sonnax hd reaction shaft

4l79 drum with gpz 3-4 clutches

carbon wide band

billet 2-4 servo

billet pinless accumulator pistons

sealed servo pin

beast shell

sonnax had 2-3 shift valve

kolene forward steels

sonnax heavy duty over run clutch hub

.500 boost valve

hp pump spring

freshly machined pump

input drum reinforcement kit

blue molded pistons

etc etc

#2

TECH Junkie

what you have labeled .110---2-3 shift---too small

what you have labeled .082---1-2 shift---will be fine

what you have labeled .092---band release---too small

two holes circled bottom left...don't touch them--they are holes for the bias oil in the AFL and TCC Reg...leaving them small will keep pressure up for both. Don't mess with 'em

hole top right...that's the low/rev clutch apply. Not really a big deal unless you plan on doing a bunch of 2-1 manual downshifts

I see no mention of drilling feed hole for the 3-4 shift

Did you block accumulator? Did you drill?

what you have labeled .082---1-2 shift---will be fine

what you have labeled .092---band release---too small

two holes circled bottom left...don't touch them--they are holes for the bias oil in the AFL and TCC Reg...leaving them small will keep pressure up for both. Don't mess with 'em

hole top right...that's the low/rev clutch apply. Not really a big deal unless you plan on doing a bunch of 2-1 manual downshifts

I see no mention of drilling feed hole for the 3-4 shift

Did you block accumulator? Did you drill?

#3

what you have labeled .110---2-3 shift---too small

what you have labeled .082---1-2 shift---will be fine perfect

what you have labeled .092---band release---too small

two holes circled bottom left...don't touch them--they are holes for the bias oil in the AFL and TCC Reg...leaving them small will keep pressure up for both. Don't mess with 'em noted!

hole top right...that's the low/rev clutch apply. Not really a big deal unless you plan on doing a bunch of 2-1 manual downshifts nah, I’ll leave that alone then

I see no mention of drilling feed hole for the 3-4 shift

Did you block accumulator? Did you drill?

what you have labeled .082---1-2 shift---will be fine perfect

what you have labeled .092---band release---too small

two holes circled bottom left...don't touch them--they are holes for the bias oil in the AFL and TCC Reg...leaving them small will keep pressure up for both. Don't mess with 'em noted!

hole top right...that's the low/rev clutch apply. Not really a big deal unless you plan on doing a bunch of 2-1 manual downshifts nah, I’ll leave that alone then

I see no mention of drilling feed hole for the 3-4 shift

Did you block accumulator? Did you drill?

i didn’t do anything with the 3-4 shift. I do not believe in using overdrive for anything except cruising. If needs to shift to overdrive, a gear change will be made. But I am open to your reasoning and recommendation.

did not do anything with the accumulator. Open to your suggestions. I do not want a harsh shift tho. I’m trying to avoid things that cause an overly harsh shift. Quick and firm I’m ok with.

what do you suggest for the 2-3 feed hole? Band release? Im all ears!

and thx!

Last edited by Kfxguy; 05-19-2021 at 02:14 PM.

#4

TECH Junkie

you say pretty stout build...and have a parts list that suggests that is true

how stout?

What RPM Range

What converter

how stout?

What RPM Range

What converter

#5

rpm is probably gonna be around 7000

#6

TECH Junkie

A: 3rd Feed

B: 2nd Feed

C: 3rd Exhaust

D: Low-Reverse Feed

E: 4th Feed

F: Check-Ball #2

G: 3rd Accumulator (Band Release)

6: Check-Ball #4

7: Overrun Feed

8: Reverse Input Feed

9: TCC

10: AFL

11: Forward Feed

12: Accumulator Valve-Train

Last edited by vorteciroc; 05-19-2021 at 03:54 PM.

The following users liked this post:

bbond105 (05-19-2021)

#7

TECH Junkie

.156 2-3

.110 band release

Be sure he is driving in D3 anytime he wants to be hard on it

Block the 4th accumulator with a setscrew, omit the piston and spring, and omit the checkball in the case

I'd also omit the #6 check ball in the valve body

are you blocking 3-2 downshift valves?

I'm assuming you're doing all of the "leak fix" methods.

Abuse bore plugs. O ring end plugs. Blocking TCC reg valve outboard. vacuum testing the rest.

p.s. throw away the kolene fwd steels.

and make sure the 3rd accum checkball is in good shape. The stock capsule and ball is fine as long as it is leak free.

You can use the superior brand replacement if you wish, but a stock capsule is OK too.

.110 band release

Be sure he is driving in D3 anytime he wants to be hard on it

Block the 4th accumulator with a setscrew, omit the piston and spring, and omit the checkball in the case

I'd also omit the #6 check ball in the valve body

are you blocking 3-2 downshift valves?

I'm assuming you're doing all of the "leak fix" methods.

Abuse bore plugs. O ring end plugs. Blocking TCC reg valve outboard. vacuum testing the rest.

p.s. throw away the kolene fwd steels.

and make sure the 3rd accum checkball is in good shape. The stock capsule and ball is fine as long as it is leak free.

You can use the superior brand replacement if you wish, but a stock capsule is OK too.

The following users liked this post:

bbond105 (05-19-2021)

Trending Topics

#8

TECH Junkie

On my Plate Diagram, The following Holes are only modified for special scenarios:

-F

-6

-8

-9

-10

-12

-F

-6

-8

-9

-10

-12

#9

TECH Junkie

F and 6 are checkball holes that you can block and then force control only through an orifice in both flow directions

9/10/12 are all bias oil that acts on the back side of a valve

9 is the TCC reg bais oil orifice ...assuming the valve is not pinned outboard...will reduce TCC reg oil pressure. (not good imo)

if the valve is pinned then drilling it larger doesn't do much...unless there is a leak in the valve endplug...then you're just puking more fluid for no real reason

10 is the afl bias oil orifice. Drilling it larger will increase feedback volume and effectively reduce AFL oil pressure. I can't see a single benefit to this unless you've found yourself having an uncontrolled AFL pressure rise situation...which across many combos...I have yet to experience.

12 is the accumulator valve bias oil orifice. Drilling it larger will increase bias oil...which will reduce accumulator oil feed...reducing its pressure...and softening shifts

peening the hole smaller will have the opposite effect and will firm shifts. If you are messing with this hole, you're likely deep into the weeds of chasing a very specific shift feel behavior. A feel that 98% of builders won't even pick up on, let alone know how to properly modify to adjust feel.

the reverse oil feed hole #8 is typically .100 or larger. Making this larger will firm the "parking lot shift" from park to reverse. Or neutral to reverse.

for most applications, this really won't need much modification.

I do some weird stuff with the reverse drum and modify it in such a way that it ends up benefiting from .110 or larger feed there. But for the typical build...if it is .100 or larger just leave it alone and you'll not have any issues.

9/10/12 are all bias oil that acts on the back side of a valve

9 is the TCC reg bais oil orifice ...assuming the valve is not pinned outboard...will reduce TCC reg oil pressure. (not good imo)

if the valve is pinned then drilling it larger doesn't do much...unless there is a leak in the valve endplug...then you're just puking more fluid for no real reason

10 is the afl bias oil orifice. Drilling it larger will increase feedback volume and effectively reduce AFL oil pressure. I can't see a single benefit to this unless you've found yourself having an uncontrolled AFL pressure rise situation...which across many combos...I have yet to experience.

12 is the accumulator valve bias oil orifice. Drilling it larger will increase bias oil...which will reduce accumulator oil feed...reducing its pressure...and softening shifts

peening the hole smaller will have the opposite effect and will firm shifts. If you are messing with this hole, you're likely deep into the weeds of chasing a very specific shift feel behavior. A feel that 98% of builders won't even pick up on, let alone know how to properly modify to adjust feel.

the reverse oil feed hole #8 is typically .100 or larger. Making this larger will firm the "parking lot shift" from park to reverse. Or neutral to reverse.

for most applications, this really won't need much modification.

I do some weird stuff with the reverse drum and modify it in such a way that it ends up benefiting from .110 or larger feed there. But for the typical build...if it is .100 or larger just leave it alone and you'll not have any issues.

#10

TECH Junkie

F and 6 are checkball holes that you can block and then force control only through an orifice in both flow directions

9/10/12 are all bias oil that acts on the back side of a valve

9 is the TCC reg bais oil orifice ...assuming the valve is not pinned outboard...will reduce TCC reg oil pressure. (not good imo)

if the valve is pinned then drilling it larger doesn't do much...unless there is a leak in the valve endplug...then you're just puking more fluid for no real reason

10 is the afl bias oil orifice. Drilling it larger will increase feedback volume and effectively reduce AFL oil pressure. I can't see a single benefit to this unless you've found yourself having an uncontrolled AFL pressure rise situation...which across many combos...I have yet to experience.

12 is the accumulator valve bias oil orifice. Drilling it larger will increase bias oil...which will reduce accumulator oil feed...reducing its pressure...and softening shifts

peening the hole smaller will have the opposite effect and will firm shifts. If you are messing with this hole, you're likely deep into the weeds of chasing a very specific shift feel behavior. A feel that 98% of builders won't even pick up on, let alone know how to properly modify to adjust feel.

the reverse oil feed hole #8 is typically .100 or larger. Making this larger will firm the "parking lot shift" from park to reverse. Or neutral to reverse.

for most applications, this really won't need much modification.

I do some weird stuff with the reverse drum and modify it in such a way that it ends up benefiting from .110 or larger feed there. But for the typical build...if it is .100 or larger just leave it alone and you'll not have any issues.

9/10/12 are all bias oil that acts on the back side of a valve

9 is the TCC reg bais oil orifice ...assuming the valve is not pinned outboard...will reduce TCC reg oil pressure. (not good imo)

if the valve is pinned then drilling it larger doesn't do much...unless there is a leak in the valve endplug...then you're just puking more fluid for no real reason

10 is the afl bias oil orifice. Drilling it larger will increase feedback volume and effectively reduce AFL oil pressure. I can't see a single benefit to this unless you've found yourself having an uncontrolled AFL pressure rise situation...which across many combos...I have yet to experience.

12 is the accumulator valve bias oil orifice. Drilling it larger will increase bias oil...which will reduce accumulator oil feed...reducing its pressure...and softening shifts

peening the hole smaller will have the opposite effect and will firm shifts. If you are messing with this hole, you're likely deep into the weeds of chasing a very specific shift feel behavior. A feel that 98% of builders won't even pick up on, let alone know how to properly modify to adjust feel.

the reverse oil feed hole #8 is typically .100 or larger. Making this larger will firm the "parking lot shift" from park to reverse. Or neutral to reverse.

for most applications, this really won't need much modification.

I do some weird stuff with the reverse drum and modify it in such a way that it ends up benefiting from .110 or larger feed there. But for the typical build...if it is .100 or larger just leave it alone and you'll not have any issues.

Quit spoiling all of my Posts!

#12

TECH Junkie

You are Most Welcome Kfxguy!

I enjoy seeing you and other members Post their build Threads with information that was learned in these Forums!

There is a great amount of good information here in the Automatic Transmission Forum!

Even from Maroon Monster (who loves to snipe Posts before I Post them myself)

I enjoy seeing you and other members Post their build Threads with information that was learned in these Forums!

There is a great amount of good information here in the Automatic Transmission Forum!

Even from Maroon Monster (who loves to snipe Posts before I Post them myself)

#13

You are Most Welcome Kfxguy!

I enjoy seeing you and other members Post their build Threads with information that was learned in these Forums!

There is a great amount of good information here in the Automatic Transmission Forum!

Even from Maroon Monster (who loves to snipe Posts before I Post them myself)

I enjoy seeing you and other members Post their build Threads with information that was learned in these Forums!

There is a great amount of good information here in the Automatic Transmission Forum!

Even from Maroon Monster (who loves to snipe Posts before I Post them myself)

i might post the next build. Itís gonna be for a vette. I have t had much time lately to post my builds.....but building I have been doing. Just finished building another turbo car, that was a 6 month project.

#14

TECH Junkie

the reverse oil feed hole #8...

I do some weird stuff with the reverse drum and modify it in such a way that it ends up benefiting from .110 or larger feed there. But for the typical build...if it is .100 or larger just leave it alone and you'll not have any issues.

Just curious.

#15

TECH Junkie

I have that weird stuff out there in multiple units.

centrifugal apply in the reverse drum is no joke in low gear

especially with anything remotely fast

transgo tries to remedy it but I'm not a fan of how they do it

centrifugal apply in the reverse drum is no joke in low gear

especially with anything remotely fast

transgo tries to remedy it but I'm not a fan of how they do it

The following users liked this post:

Kfxguy (05-20-2021)

#18

TECH Junkie

add away

#20

TECH Junkie

-Do not plug the Holes in the Reverse-Input Piston.

-Use Early THM700-R4 Waved Steel Plate

-Use Early THM700-R4 Frictions

-Use Late 4L60E Turbulator Steels

-Use corresponding Selective Backing-Plate

-Use a set of Trans-Brake Springs in the Reverse-Input Drum with a 0.035" Bleed Hole in the corner of the Drum.