LQ4 into a 3rd Gen/1972 Nova

#443

tsnow678... I like that idea of wrapping the belt around the left side of the idler for option 4, wouldn't add much length to the belt but would give better wrap for the p/s pump... thanks!

Mark... Plan all along was to make sure hood clearance happened... I still posted these options up because in prettymuch all of them, if I had to make my own bracket to relocate the alt, the alt wouldn't have to be lowered by too much so it shouldn't alter any of these options too much.

Going to mock up the hood tomorrow after work. I'm going to be shocked if the hood fit the truck accessories STILL even after I removed the subframe bushings...

squee... I'm not sure on a 4th gen to be honest, you'd likely have to make or buy an adapter for the hoydroboost to make it bolt up to (I'm assuming) the 4 bolt pattern the 4th gen brake booster uses to mount to the firewall. Another guy is already interested but I'll PM you if it happens to fall through.

Mark... Plan all along was to make sure hood clearance happened... I still posted these options up because in prettymuch all of them, if I had to make my own bracket to relocate the alt, the alt wouldn't have to be lowered by too much so it shouldn't alter any of these options too much.

Going to mock up the hood tomorrow after work. I'm going to be shocked if the hood fit the truck accessories STILL even after I removed the subframe bushings...

squee... I'm not sure on a 4th gen to be honest, you'd likely have to make or buy an adapter for the hoydroboost to make it bolt up to (I'm assuming) the 4 bolt pattern the 4th gen brake booster uses to mount to the firewall. Another guy is already interested but I'll PM you if it happens to fall through.

#444

Well I'll be a sonofabtich... the hood clears the stock truck accessories/alternator even with no subframe bushings!

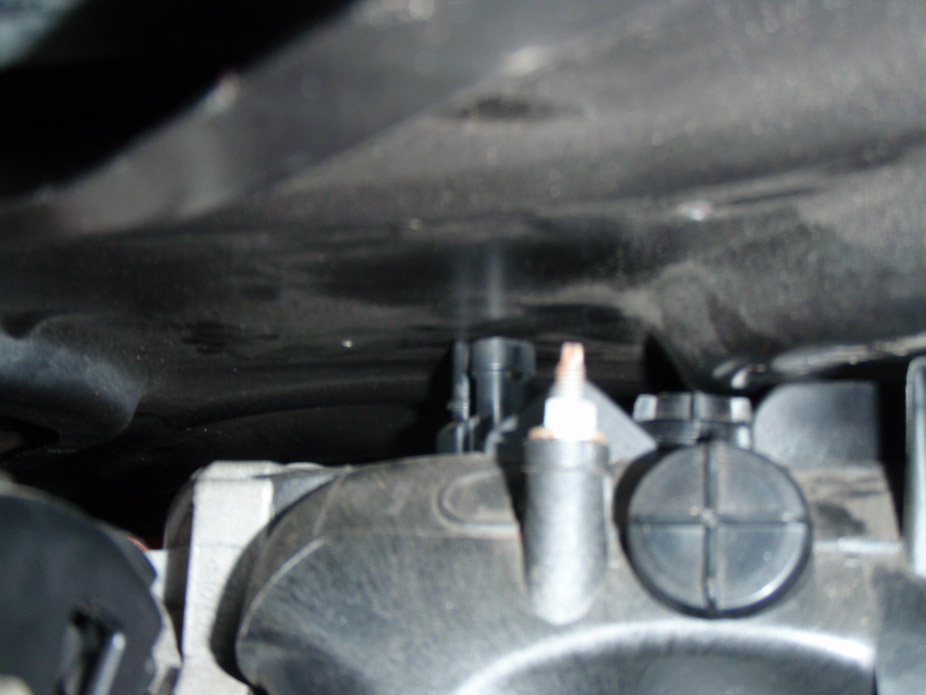

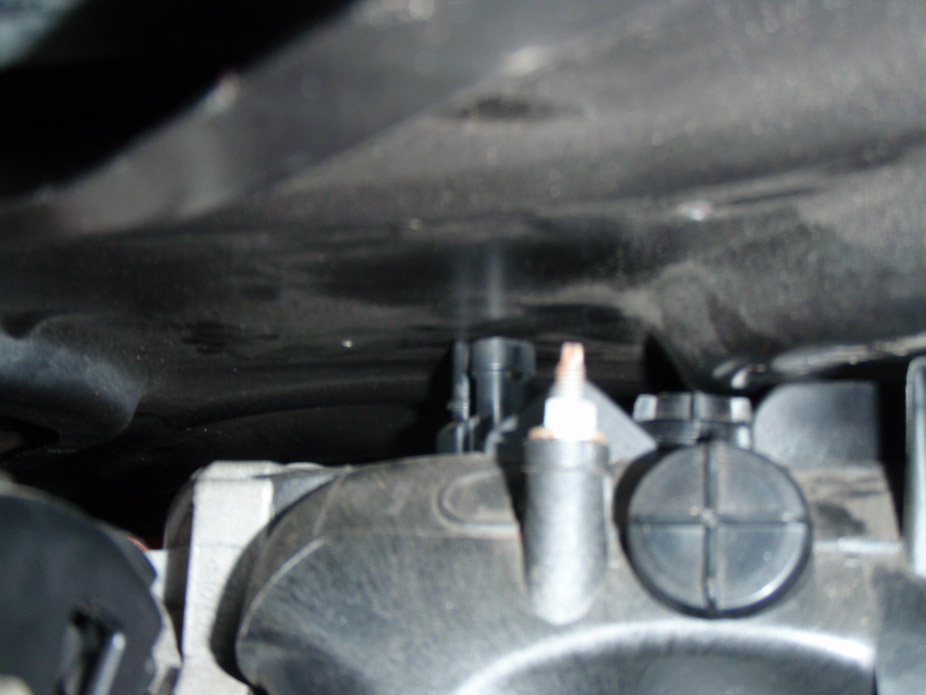

This sensor was the only thing getting in the way of the hood fully closing... anyone know what it's for??

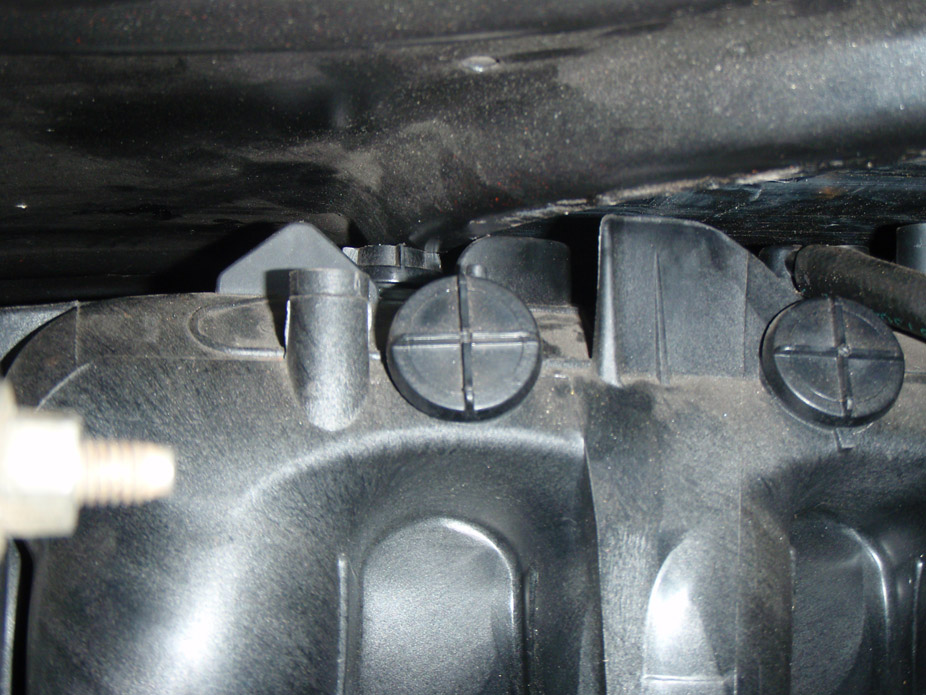

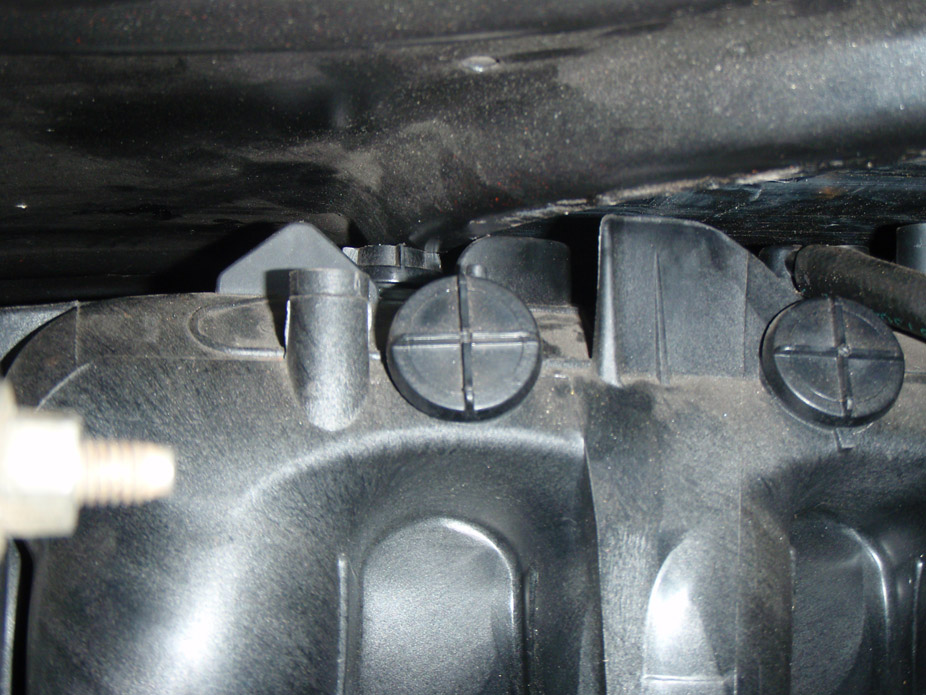

And a bunch of the plastic bs on the intake is all that comes close, will trim off and make it look a bit better...

This sensor was the only thing getting in the way of the hood fully closing... anyone know what it's for??

And a bunch of the plastic bs on the intake is all that comes close, will trim off and make it look a bit better...

#447

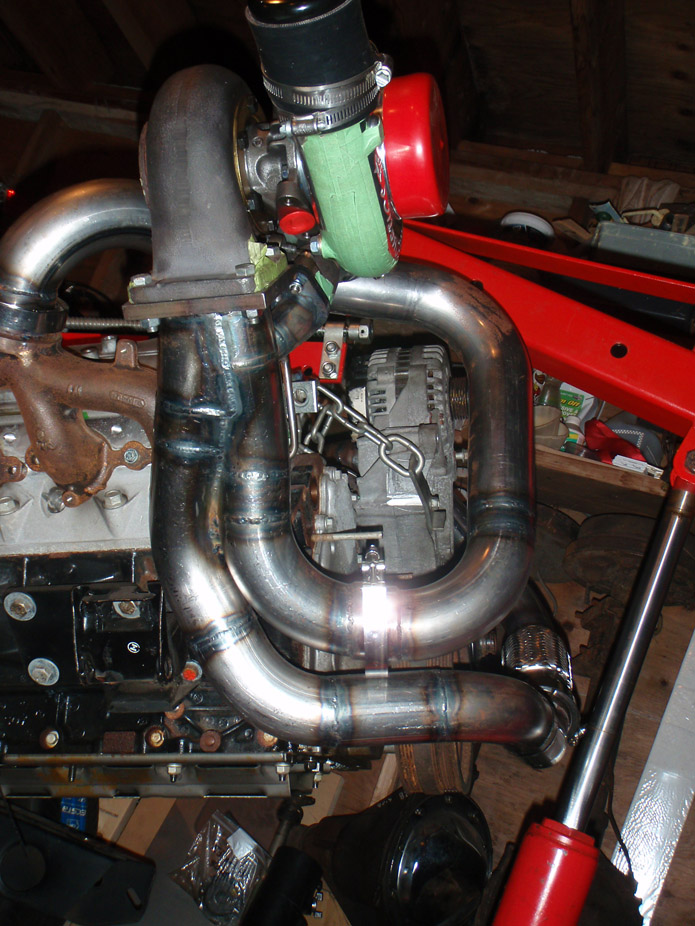

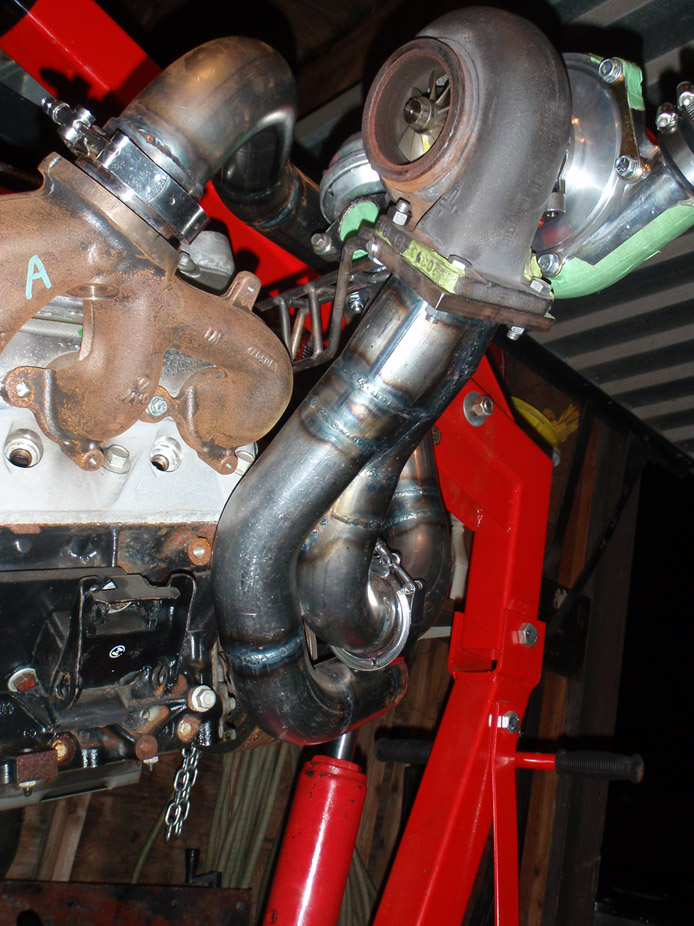

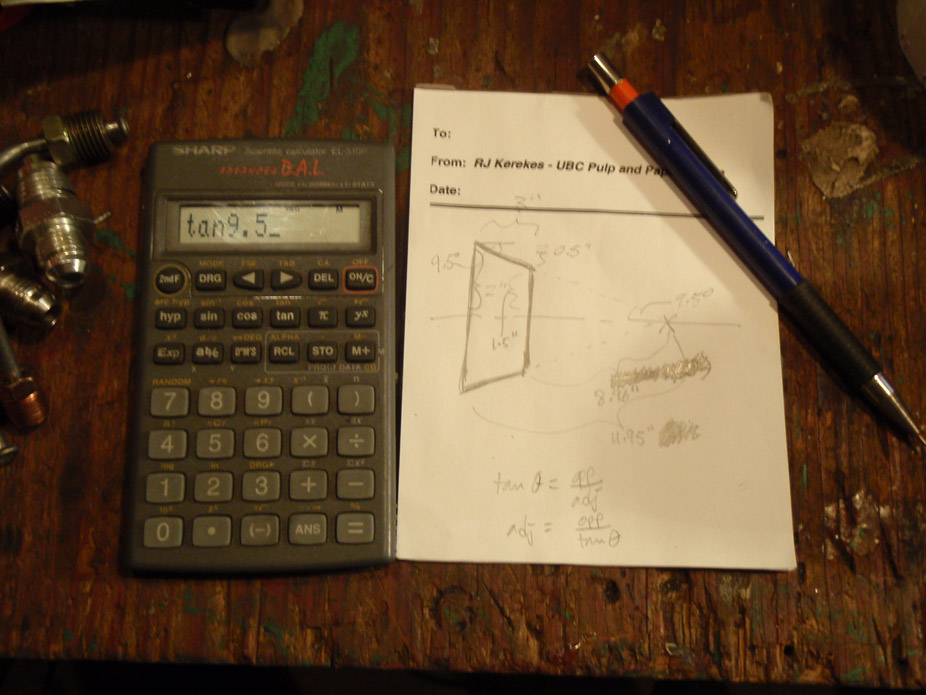

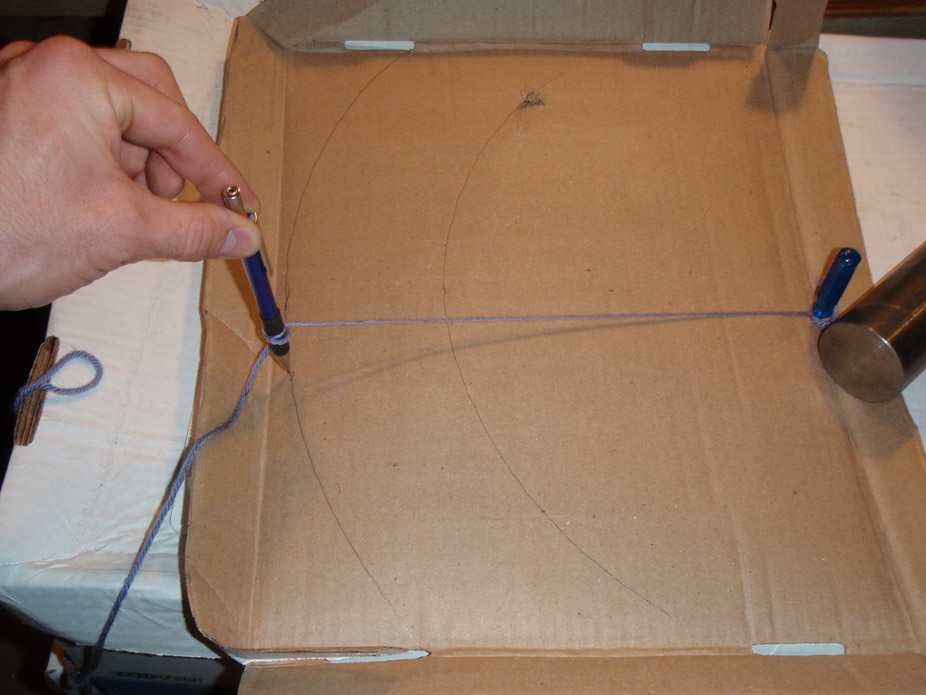

Started making the downpipe, got it to the point where I could finish the the wastegate dump pipe with the engine out of the car, just wanted to get it far enough to make sure it'd fit the inner fenderwell no problem.

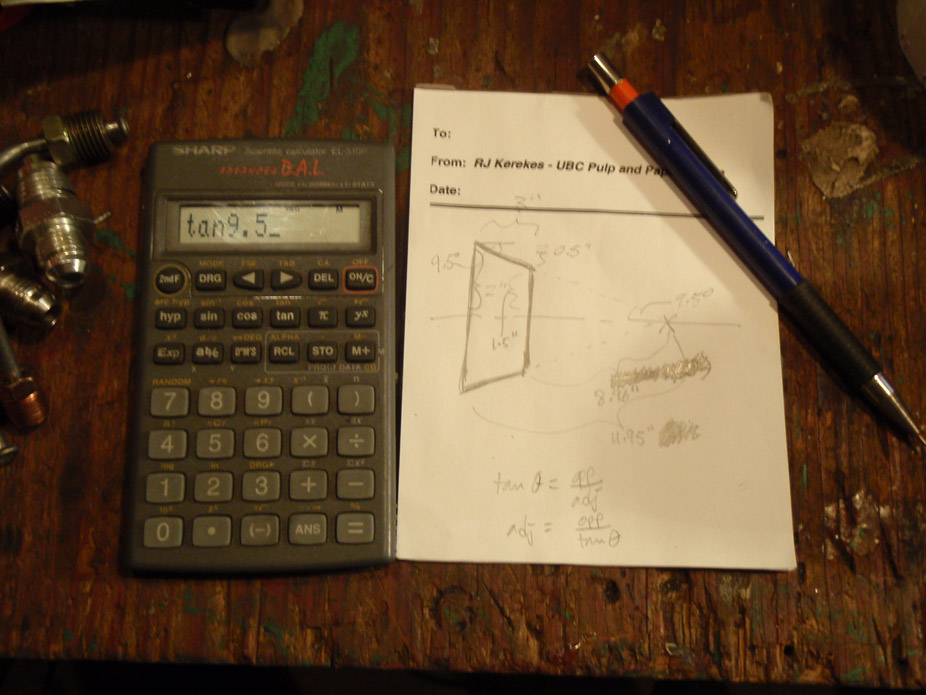

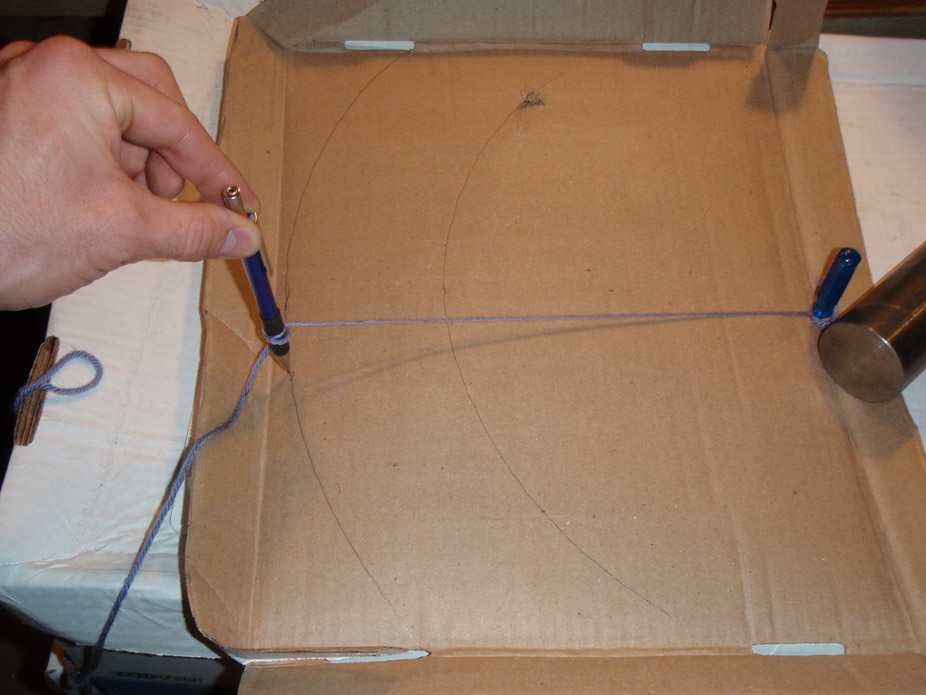

Idea is to go from the TC76's 3" outlet to a 4" to eliminate backpressure. Wastegate dump pipe will merge with downpipe right at the cone section.

Like hell I'm paying $25-30 for a cone, just needs a bit of garage engineering...

Idea is to go from the TC76's 3" outlet to a 4" to eliminate backpressure. Wastegate dump pipe will merge with downpipe right at the cone section.

Like hell I'm paying $25-30 for a cone, just needs a bit of garage engineering...

#450

TECH Fanatic

Your doing great! Im also working on my hot side, Any idea what hooks to the wastegate so I bleeds boost? I have one with a fitting on the top, and one in the side(bottom).

#451

Yup it's all tig'd. Started off rough but after lots of practice and a bunch of good tips form the master welder at work, I've improved. Started tigging aluminum for the first time last night while starting the cold side piping, first couple beads actually weren't too bad!

#457

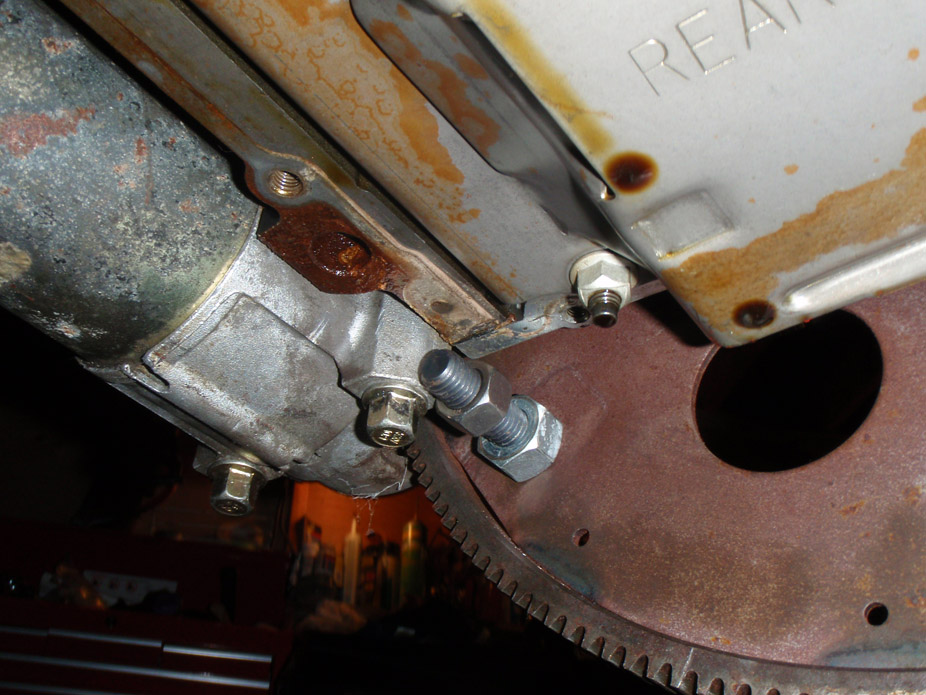

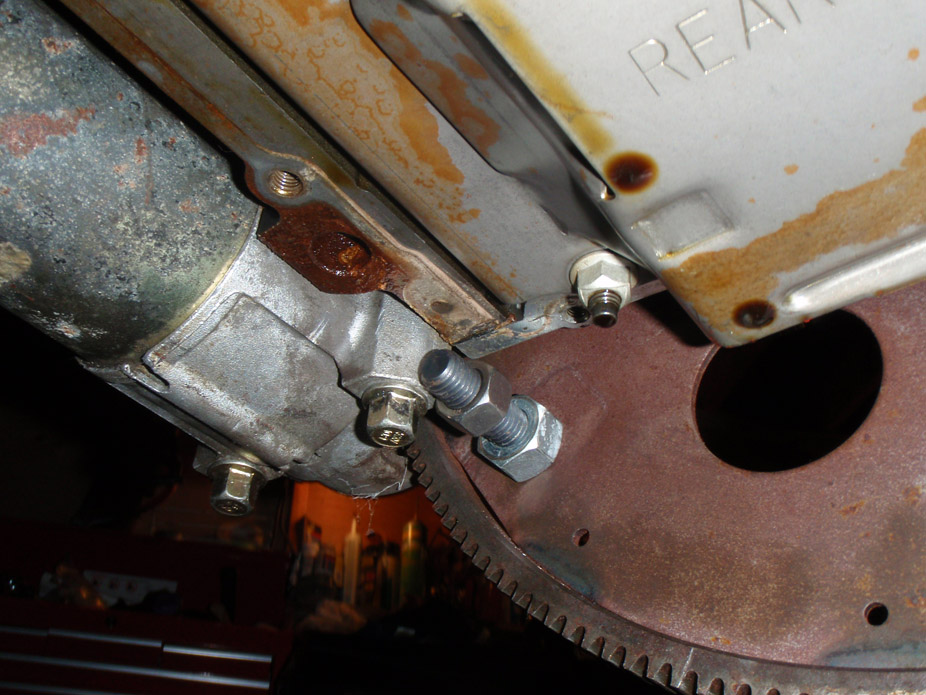

Nothing exciting in this post, just though I'd share a tip, for how to lock up the flywheel/flexplate when trying to loosen/tighten those 6 crank bolts, check the black bolt...

Tightened the 1st nut down hard then put the 2nd nut on there to protect the threads/block, then rotated flexplate till the bolt/nut hit it...

Lonely looking, this is gonna be a lonnnng weekend of wire wheelin' and cleaning so I can paint it.

Tightened the 1st nut down hard then put the 2nd nut on there to protect the threads/block, then rotated flexplate till the bolt/nut hit it...

Lonely looking, this is gonna be a lonnnng weekend of wire wheelin' and cleaning so I can paint it.

#458

TECH Addict

iTrader: (3)

I have a tip for you if you are going to run an aftermarket oil pan. While you have access to oil pan rail. The factory didnt drill and tap one hole in the rail. It is right in front of the oil filter location.

Nice work on the firewall ferrule! How will it attach to the firewall?

Nice work on the firewall ferrule! How will it attach to the firewall?

#459

I plan on running a modified stock LQ4 oil pan, and it's quite rigid, so I'm not too worried about the missing hole, but that's a good tip anyways

The firewall thingy work like this: the split front piece goes around the harness on the engine bay side of the firewall, the slotted back piece slides over the harness on the cockpit side of the firewall, then the bolts screw thru the front piece into the back piece, sandwiching the firewall between the machined step in the backside of the front piece and the lip of the back piece. Pics will help it make sense when I install it later.

The firewall thingy work like this: the split front piece goes around the harness on the engine bay side of the firewall, the slotted back piece slides over the harness on the cockpit side of the firewall, then the bolts screw thru the front piece into the back piece, sandwiching the firewall between the machined step in the backside of the front piece and the lip of the back piece. Pics will help it make sense when I install it later.

#460

Painted the block VHT engine paint flat black, wasn't expecting it to be that flat, but whatever it won't be too visible...

Figure it's best not to leave it to just those 6 bolts to hold onto the engine, so welded the stands in...

TIG welder is by far the best investment I've made so far, and the rolling cart is by far the most useful thing I've fabricated yet, it's so easy to make accessible...

Not the cleanest welds but I had to change to at least 196 different straddle/crouch/hunch positions to get the angles...

And then I started playing with aluminum...

And started making a coil relocation bracket. Making (more like replicating) the bends was NOT fun but will be worth it, ran out of Al. plate today, but the first one turned out better that I was expecting.

Was originally going bolt to the side of the block below the manifolds but now I kinda want to show it (them) off either on the firewall or bolted to the back of the heads hovering over the aft end of the valvecovers...

Figure it's best not to leave it to just those 6 bolts to hold onto the engine, so welded the stands in...

TIG welder is by far the best investment I've made so far, and the rolling cart is by far the most useful thing I've fabricated yet, it's so easy to make accessible...

Not the cleanest welds but I had to change to at least 196 different straddle/crouch/hunch positions to get the angles...

And then I started playing with aluminum...

And started making a coil relocation bracket. Making (more like replicating) the bends was NOT fun but will be worth it, ran out of Al. plate today, but the first one turned out better that I was expecting.

Was originally going bolt to the side of the block below the manifolds but now I kinda want to show it (them) off either on the firewall or bolted to the back of the heads hovering over the aft end of the valvecovers...