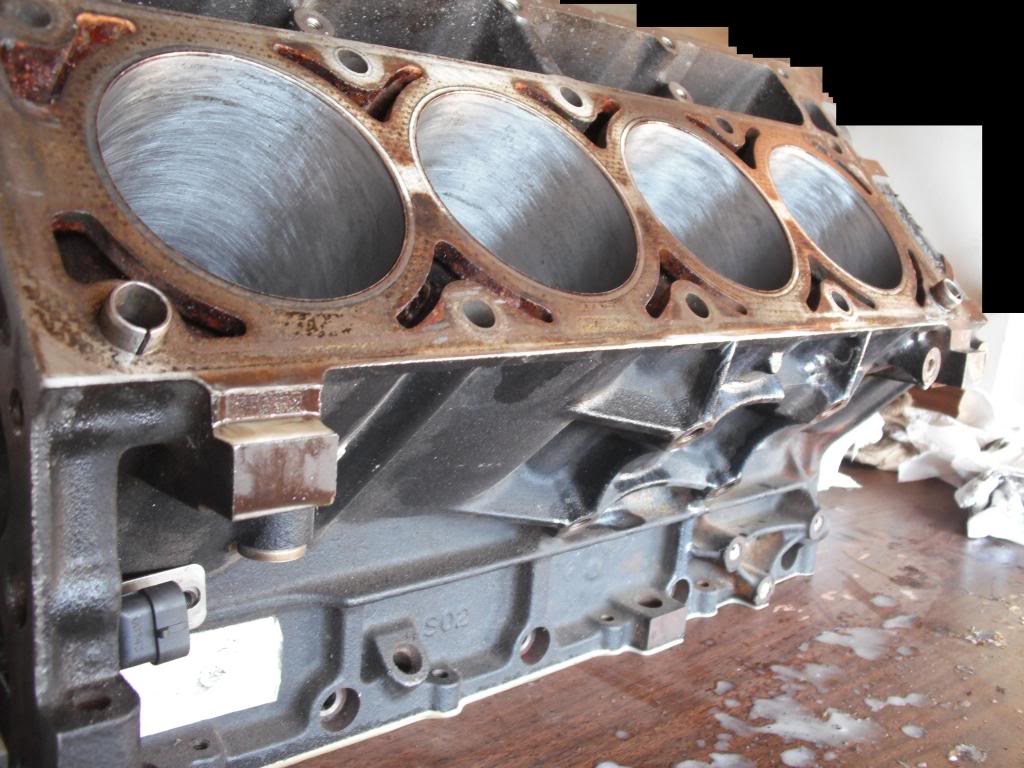

how I honed my block, w/ pics

#1

I'm sure we've all seen the pics of the DIY honing, typically using the hone called either a "dingle-ball" or "bottle-brush"

I've used one, successfully, they're very easy and safe. But they're nothing like a Sunnen CK-10 that many machine shops have been using for decades.

I'm sure most of you will insist your honing be done on a Sunnen or similar.

But this time, I honed my LM7 block with the "3-finger" or "3-stone" style.

It's much cheaper.

Now, before pics, I thought mineral spirits were clear. But when I poured these, they were white.

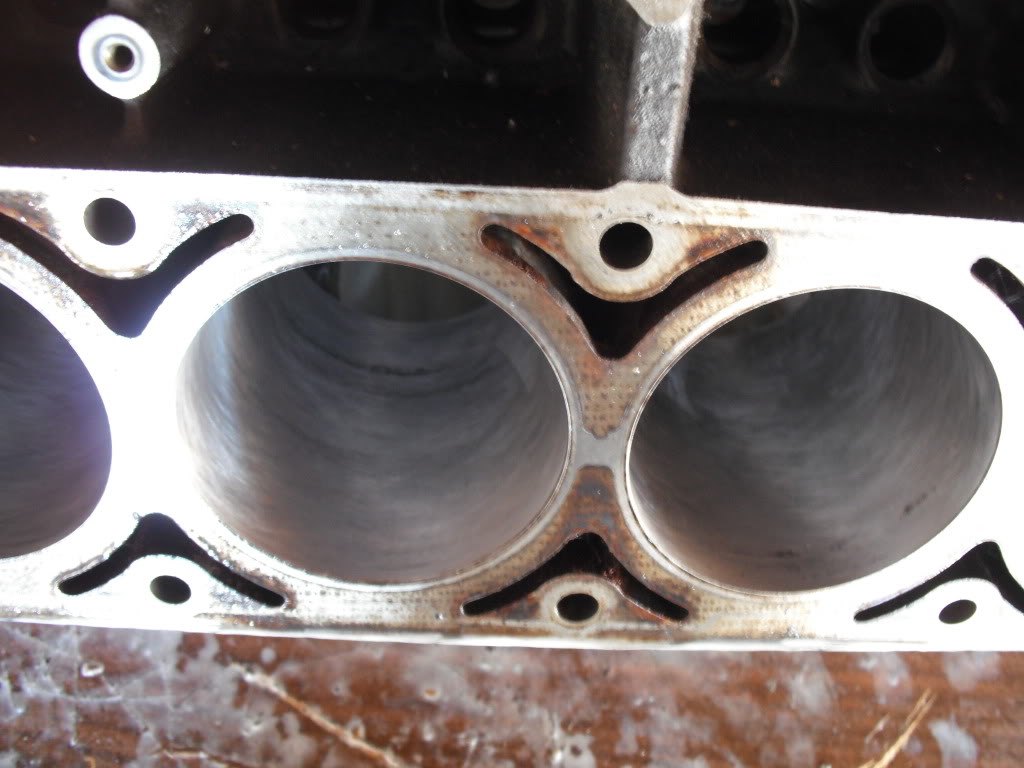

In the first pic you'll see what all you need to copy me.

I think I took that pic after doing a cylinder. This next one, I'm sure was after I had done a cylinder.

and closer in

I've used one, successfully, they're very easy and safe. But they're nothing like a Sunnen CK-10 that many machine shops have been using for decades.

I'm sure most of you will insist your honing be done on a Sunnen or similar.

But this time, I honed my LM7 block with the "3-finger" or "3-stone" style.

It's much cheaper.

Now, before pics, I thought mineral spirits were clear. But when I poured these, they were white.

In the first pic you'll see what all you need to copy me.

I think I took that pic after doing a cylinder. This next one, I'm sure was after I had done a cylinder.

and closer in

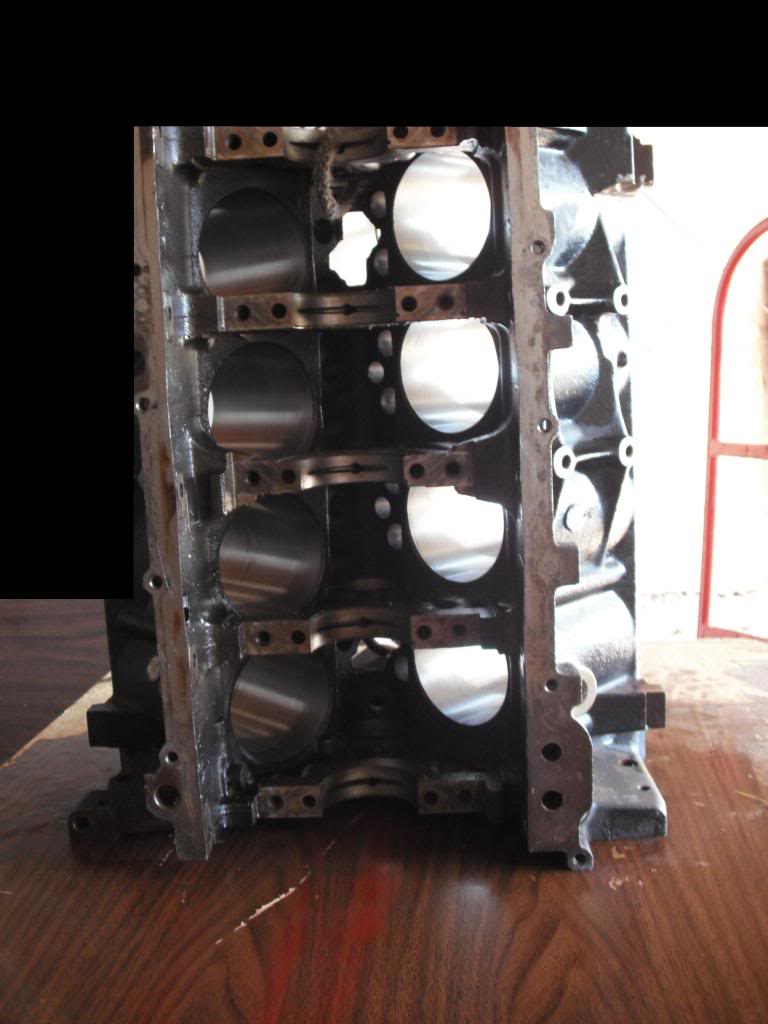

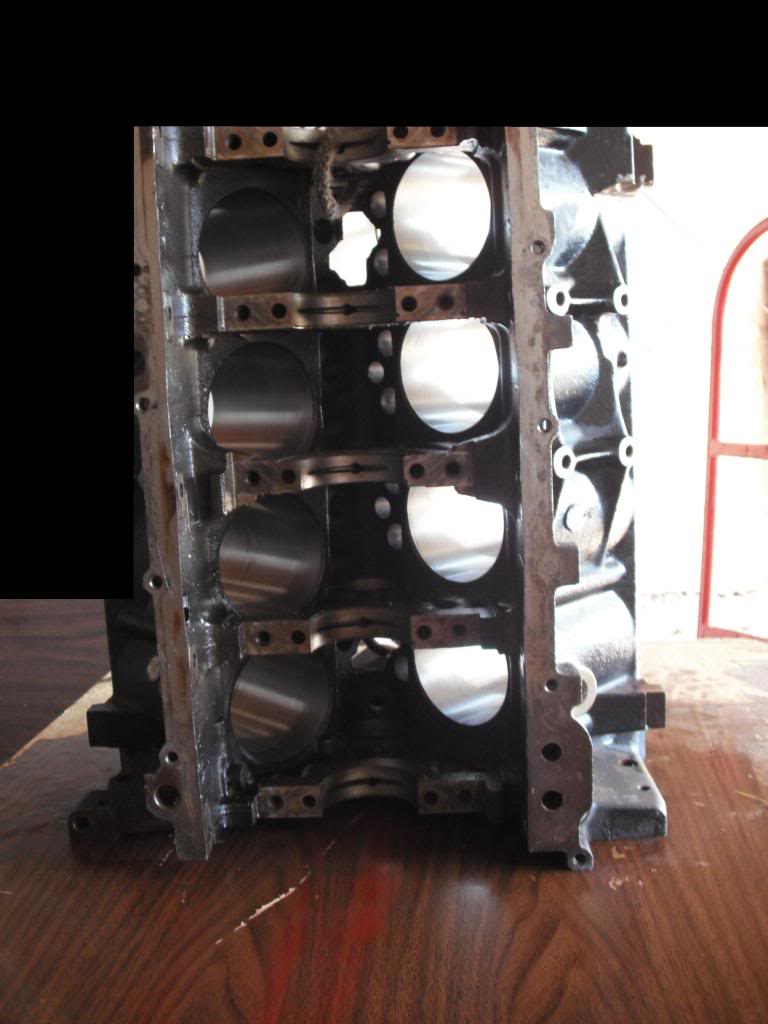

#2

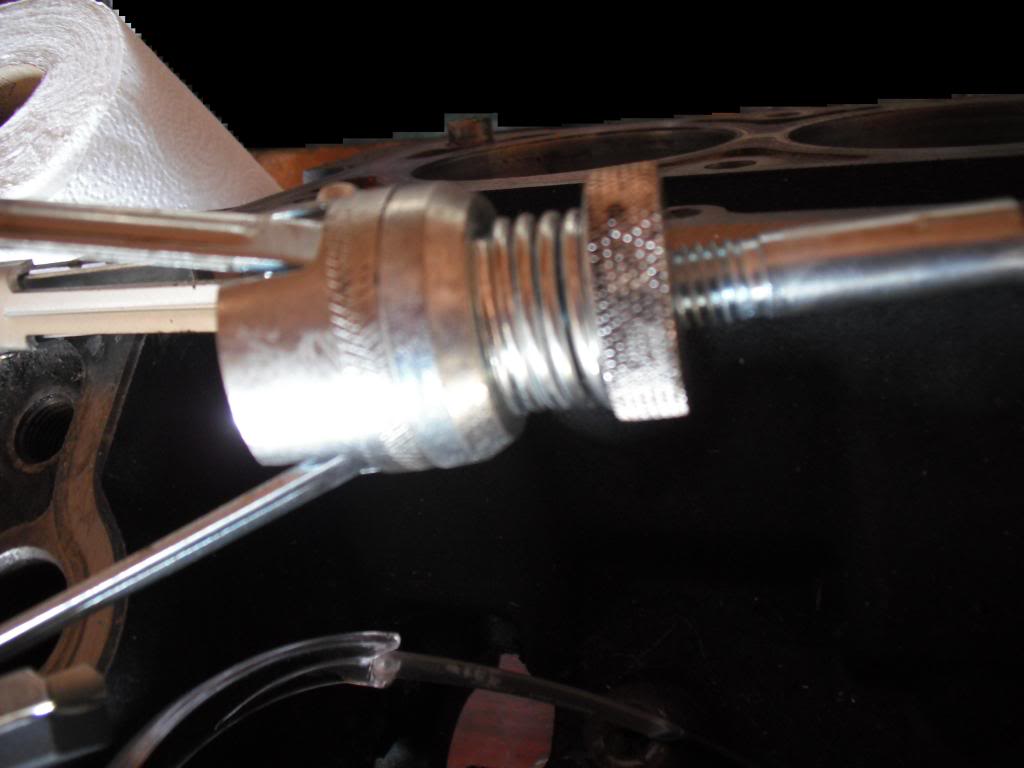

This was more difficult than the other style of hone in having to be more careful about plunging too far, or pulling too far. I dinged the stones a wee bit.

It's also more difficult in adjusting the pre-load spring. I knew I didn't want coil bind, just like valvesprings, but I ran it relatively close:

It's also more difficult in adjusting the pre-load spring. I knew I didn't want coil bind, just like valvesprings, but I ran it relatively close:

#3

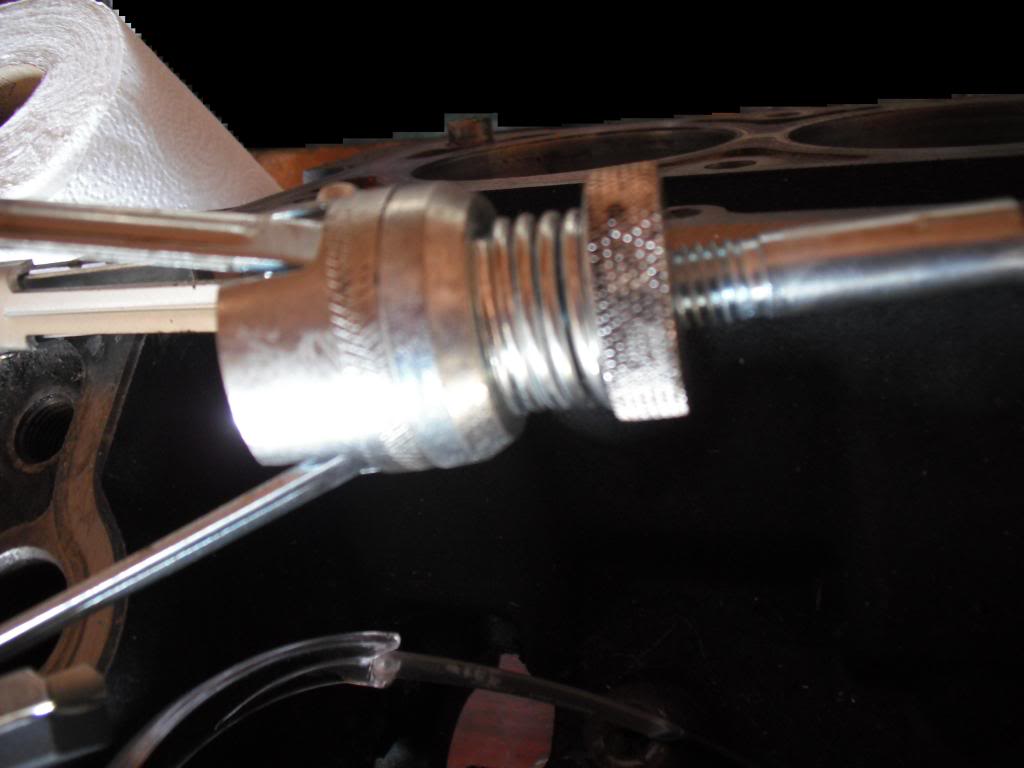

I ran the drill at about half speed, and I ran my arms near full speed, to get the cross hatch angle I found in there from GM. Lots of try-it-and-see. I had to dip the hone in the spirits about 3-4 times per cylinder.

This next pic is about 5 seconds in:

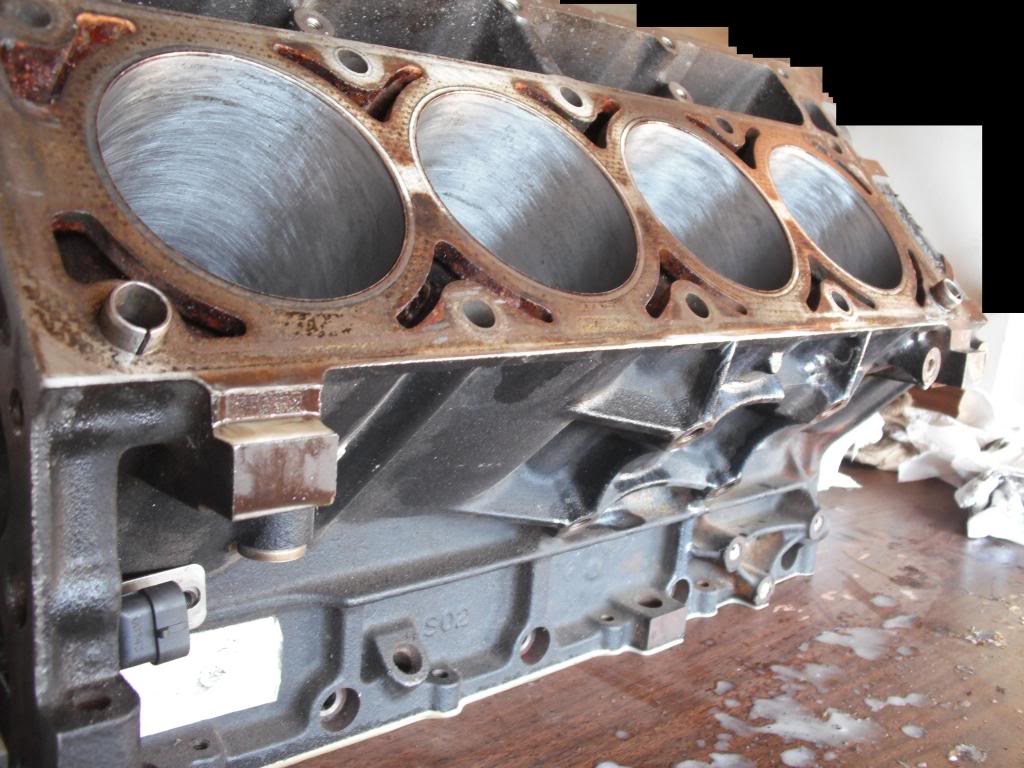

Then I finished one side, wiped them all out, and sprayed the WD40

This next pic is about 5 seconds in:

Then I finished one side, wiped them all out, and sprayed the WD40

#7

Not counting the drill or electricity, nor the safety glasses, but with 1/2 the cost of the hone, (it should do another V8 yet) 1/2 the spirits, (didn't need that big a quantity)the scotch brite pad and the paper towels, the cost was $20.

As I was wiping the table off, I was able to get an idea of how much iron and stone I had removed.

As I was wiping the table off, I was able to get an idea of how much iron and stone I had removed.

Trending Topics

#8

I'm not clear on how many miles this should extend the life of the standard-bore, probably not as long as a power hone on a Sunnen, but this is sure to be better than just running it the way I got it, with probably around 100,000 miles on it.

#9

#10

Oh, yeah, that's real bright. Don't even ask what grit the stones are, or how the pre-load on this compares with the pre-load of the Sunnen. Just start with your criticism.

#11

9 Second Club

iTrader: (31)

but, i'd have to agree that you might have gotten a little over-aggressive with the hone-job. I hope it doesnt come back to bite you in the ***.

Props for doing it yourself! I'm also not sure i would have use some of those stones....they've seen better days.

#16

LS1Tech Premium Sponsor

iTrader: (5)

Congrats for having the guts to try it yourself, but I'll stick with the Sunnen with the torque plate

__________________

Largest Stocking Distributor of LS-x Engines / CHECK OUT OUR NEW WEBSITE!

COMP - FAST - PACESETTER - DIAMOND RACING - EAGLE SPECIALTY PRODUCTS - CALLIES - COMETIC GASKETS

RAM CLUTCHES - MOSER ENGINEERING - KOOK'S HEADERS - ARP - GM BOLTS AND GASKETS - MSD - NGK

POWERBOND - ASP - AND MORE!

Largest Stocking Distributor of LS-x Engines / CHECK OUT OUR NEW WEBSITE!

COMP - FAST - PACESETTER - DIAMOND RACING - EAGLE SPECIALTY PRODUCTS - CALLIES - COMETIC GASKETS

RAM CLUTCHES - MOSER ENGINEERING - KOOK'S HEADERS - ARP - GM BOLTS AND GASKETS - MSD - NGK

POWERBOND - ASP - AND MORE!

#17

TECH Regular

iTrader: (1)

Mineral spirits? Are you sure they didn't tell you to use that for cleaning after honing? On every engine I have ever honed I used 30w oil but everyone is different when it comes to prep and assembly on their engine. As for the 3-stone it is a little aggressive to use for finish honing. It is best to get a rough hone at the shop and then finish hone to the bore size you are looking for at home.

The only time I use a 3-stone is to cut through rust and what not on an old core I am building to get a good start and to see if an overbore is necessary.

The bottle/ball/dingle hone is the best(my opinion) for actual finish before assembly. Not to mention, i have over 12 engine builds on a single hone and its still going.

The only time I use a 3-stone is to cut through rust and what not on an old core I am building to get a good start and to see if an overbore is necessary.

The bottle/ball/dingle hone is the best(my opinion) for actual finish before assembly. Not to mention, i have over 12 engine builds on a single hone and its still going.

#18

#19

Mineral spirits? Are you sure they didn't tell you to use that for cleaning after honing? On every engine I have ever honed I used 30w oil but everyone is different when it comes to prep and assembly on their engine. As for the 3-stone it is a little aggressive to use for finish honing. It is best to get a rough hone at the shop and then finish hone to the bore size you are looking for at home.

The only time I use a 3-stone is to cut through rust and what not on an old core I am building to get a good start and to see if an overbore is necessary.

The bottle/ball/dingle hone is the best(my opinion) for actual finish before assembly. Not to mention, i have over 12 engine builds on a single hone and its still going.

The only time I use a 3-stone is to cut through rust and what not on an old core I am building to get a good start and to see if an overbore is necessary.

The bottle/ball/dingle hone is the best(my opinion) for actual finish before assembly. Not to mention, i have over 12 engine builds on a single hone and its still going.

I do agree with you on the choice of hone, but I couldn't until I had tried both.

#20

LS1Tech Premium Sponsor

iTrader: (5)

The extra cost associated with the new rings alone that will be purchased when this one is consuming crazy amounts of oil and needs a rebuild will come close to offsetting the cost of getting the work done by a machine shop.

__________________

Largest Stocking Distributor of LS-x Engines / CHECK OUT OUR NEW WEBSITE!

COMP - FAST - PACESETTER - DIAMOND RACING - EAGLE SPECIALTY PRODUCTS - CALLIES - COMETIC GASKETS

RAM CLUTCHES - MOSER ENGINEERING - KOOK'S HEADERS - ARP - GM BOLTS AND GASKETS - MSD - NGK

POWERBOND - ASP - AND MORE!

Largest Stocking Distributor of LS-x Engines / CHECK OUT OUR NEW WEBSITE!

COMP - FAST - PACESETTER - DIAMOND RACING - EAGLE SPECIALTY PRODUCTS - CALLIES - COMETIC GASKETS

RAM CLUTCHES - MOSER ENGINEERING - KOOK'S HEADERS - ARP - GM BOLTS AND GASKETS - MSD - NGK

POWERBOND - ASP - AND MORE!