Which Cam Lobes to Use for 7000rpm+ LS7, w/ Stainless 2.205" Valves?

#1

I got a set of new LS7 cnc's heads for <$1000. In sticking to my budget I had to forgo the ti intake valves (which run about $800 a set), and get stainless which are about 20% heavier.

For reference:

2.205 118.4g (the LS7 intake in SS from REV)

2.180 114.6g (a L92 valve in SS we use from REV)

2.160 106.5g (stock L92 replacement SS from REV)

1.600 92.3g (for reference an SS exhaust valve)

Stock LS7 Ti intake valves are probably in the 95g range as a guess.

Richard at West Coast Cylinder Heads hooked me up with the most serious valve springs that can still be used with hydraulic rollers, as I plan on using the GMPP Cadillac lifters. It's common knowlege that a lift much over 25% of the valves diameter usually yields very little gain in flow. The LS7 head is no exception.

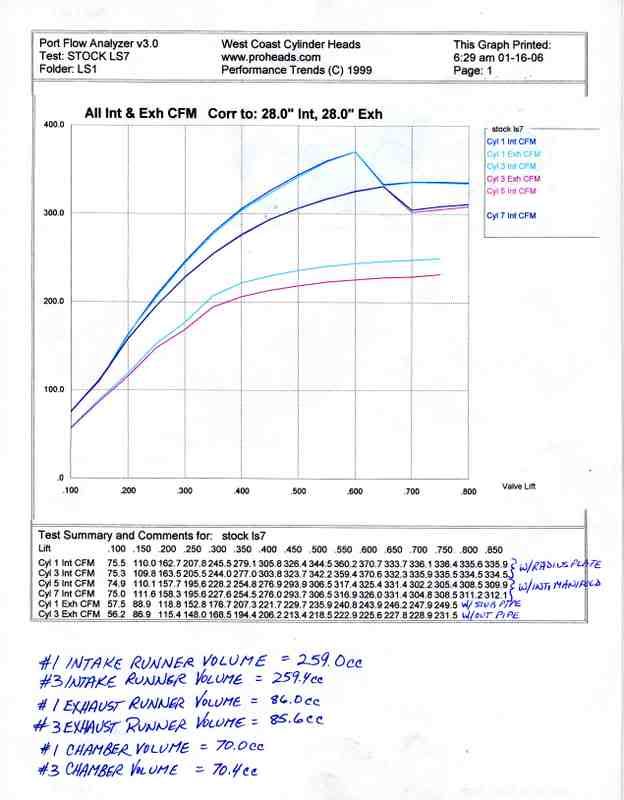

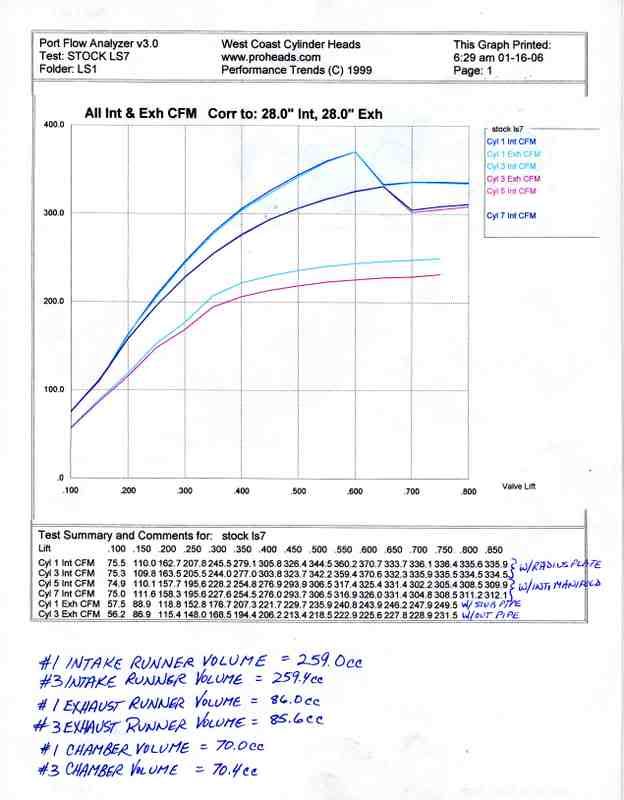

As you can see from the flow data below. The flow at 25% of the 2.205" intake valve diameter (at a lift of ~.550"), to its max flow which is at .650" lift, the flow only increases 4.4% with the manifold on. And with the manifold off the flow actually decreases at lifts much greater than the magical 25% diameter lift height!

Here's a chart I made regarding piston velocity: @ the LS7s stock 4.000” stroke which I plan on using.

RPM FPM

6000 4000 safe (street)

6300 4200

6500 4333 max (street)

6750 4500

7000 4666 LS7 sits here stock

7200 4800

7500 5000 GENERALLY CONSIDERED SAFE IF ALL FORGED COMPONENTS.

7650 5100 R07 nascar engine

8000 5333

8200 5466 Tosto Drag LSx

"During GM's reliability testing of this engine in its prototype phase, the LS7 was remarked to have been repeated tested to be 8000 rpm capable, although power was not made at that rpm level, due to the restraints of the camshaft's profile and the intake manifold ability to flow required air at that engine speed."

I see no reason a forged LS motor with a 4" stroke shouldn't have a 7500 rpm rev limit. 5000 fpm is considered a safe limit with many engine builders if the bottom end is built entirely of all forged components.

Unlike GM I can use whatever cam I want, so my limiting factor has become my valvetrain. I'm hoping to get around this with some seriously honkin valvesprings and stout push rods. Here are the springs I currently have.

The valves are REV stainless steel valves part numbers X1131 for the intakes and X1137 for the exhaust. And use 10 deg locks.

The Springs:

seat diameter: 1.450" (My LS7 heads were machined to take BBC size springs)

installed height: 1.855"

seat pressure: 163 lbs

.600" lift: 404 lbs

.650" lift: 426 lbs

.660" lift: 430 lbs (max rec lift)

I havn't measured coil bind yet.

Now the limiting factor is the 1.8:1 LS7 rockers give some lobes too damn much lift. And the other limiting factor is that I fear some of the more popular cam profiles might be too aggressive for such a heavy valve at 7500 rpm.

For example a comp cams LSK 240 duration at .050" lift lobe would have a lift of 0.687" lift with the 1.8:1 rockers! Too much for even my crazy BBC springs! If you want to figure out the lift that a lobe has that's quoted fot 1.7:1 rockers just multiply by 1.0588 to get the new lift with 1.8:1 rockers.

Common LS based comp lobes at 240 duration at .050" lift.

XFI (at 242) 0.648"

XER (at 240) 0.645"

LSK (at 240) 0.687"

Richard at WCCH suggested that I not go too much over 0.630" lift. Looking at the flow data of the heads with the manifold on I can see why. I'd like to keep using stock style lifters to help with the budget. So now the question is which lobe is going to help me get there?

I need something gentle, but of course don't want to sacrifice any ramp speed that I don't have to.

For reference:

2.205 118.4g (the LS7 intake in SS from REV)

2.180 114.6g (a L92 valve in SS we use from REV)

2.160 106.5g (stock L92 replacement SS from REV)

1.600 92.3g (for reference an SS exhaust valve)

Stock LS7 Ti intake valves are probably in the 95g range as a guess.

Richard at West Coast Cylinder Heads hooked me up with the most serious valve springs that can still be used with hydraulic rollers, as I plan on using the GMPP Cadillac lifters. It's common knowlege that a lift much over 25% of the valves diameter usually yields very little gain in flow. The LS7 head is no exception.

As you can see from the flow data below. The flow at 25% of the 2.205" intake valve diameter (at a lift of ~.550"), to its max flow which is at .650" lift, the flow only increases 4.4% with the manifold on. And with the manifold off the flow actually decreases at lifts much greater than the magical 25% diameter lift height!

Here's a chart I made regarding piston velocity: @ the LS7s stock 4.000” stroke which I plan on using.

RPM FPM

6000 4000 safe (street)

6300 4200

6500 4333 max (street)

6750 4500

7000 4666 LS7 sits here stock

7200 4800

7500 5000 GENERALLY CONSIDERED SAFE IF ALL FORGED COMPONENTS.

7650 5100 R07 nascar engine

8000 5333

8200 5466 Tosto Drag LSx

"During GM's reliability testing of this engine in its prototype phase, the LS7 was remarked to have been repeated tested to be 8000 rpm capable, although power was not made at that rpm level, due to the restraints of the camshaft's profile and the intake manifold ability to flow required air at that engine speed."

I see no reason a forged LS motor with a 4" stroke shouldn't have a 7500 rpm rev limit. 5000 fpm is considered a safe limit with many engine builders if the bottom end is built entirely of all forged components.

Unlike GM I can use whatever cam I want, so my limiting factor has become my valvetrain. I'm hoping to get around this with some seriously honkin valvesprings and stout push rods. Here are the springs I currently have.

The valves are REV stainless steel valves part numbers X1131 for the intakes and X1137 for the exhaust. And use 10 deg locks.

The Springs:

seat diameter: 1.450" (My LS7 heads were machined to take BBC size springs)

installed height: 1.855"

seat pressure: 163 lbs

.600" lift: 404 lbs

.650" lift: 426 lbs

.660" lift: 430 lbs (max rec lift)

I havn't measured coil bind yet.

Now the limiting factor is the 1.8:1 LS7 rockers give some lobes too damn much lift. And the other limiting factor is that I fear some of the more popular cam profiles might be too aggressive for such a heavy valve at 7500 rpm.

For example a comp cams LSK 240 duration at .050" lift lobe would have a lift of 0.687" lift with the 1.8:1 rockers! Too much for even my crazy BBC springs! If you want to figure out the lift that a lobe has that's quoted fot 1.7:1 rockers just multiply by 1.0588 to get the new lift with 1.8:1 rockers.

Common LS based comp lobes at 240 duration at .050" lift.

XFI (at 242) 0.648"

XER (at 240) 0.645"

LSK (at 240) 0.687"

Richard at WCCH suggested that I not go too much over 0.630" lift. Looking at the flow data of the heads with the manifold on I can see why. I'd like to keep using stock style lifters to help with the budget. So now the question is which lobe is going to help me get there?

I need something gentle, but of course don't want to sacrifice any ramp speed that I don't have to.

Last edited by GIGAPUNK; 03-09-2010 at 04:12 PM.

#4

LS1 Tech Administrator

iTrader: (14)

If you're wanting to stay hydraulic with lower lifts (and heavy valves), I'd recommend the Comp Xtreme Marine hydraulic lobes. A 248 lobe has .333" tappet lift giving .599" at the valve.

If you're willing to go a little more aggressive, the EPS lobes from Engine Power Systems are also an Endurance profile, but are more like a .355" lobe (which gives .639" lift with a 1.8 rocker).

An SP solid roller lobe will work with a hydraulic lifter and are very smooth, but it's over .380" so we're talking a .680+" cam with a 1.8 rocker.

If you're willing to go a little more aggressive, the EPS lobes from Engine Power Systems are also an Endurance profile, but are more like a .355" lobe (which gives .639" lift with a 1.8 rocker).

An SP solid roller lobe will work with a hydraulic lifter and are very smooth, but it's over .380" so we're talking a .680+" cam with a 1.8 rocker.

__________________

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

#5

TECH Fanatic

GIGAPUNK,

You need to ask yourself some questions well before trying to pick out cam lobes. Here are a few thoughts:

What are your performance and driveability goals for the engine and vehicle?

How much money are you willing to spend overall? This will detrmine if you can meet your goals. Are you willing to change you goals/mind if what you want won't work or will be too costly?

If you want to spin 7500 (and make decent power somewhere near there), you need to realize that production/FAST intake manifolds aren't in the cards. Think "sheet metal" or a single plane. Lots of work, and lots of money to make 'em work.

Flinging around valves approaching 120 gm and the very heavy springs needed with them is a BIG challenge for hydraulic lifters, as is getting lots of air into an engine this size with intakes that back up before .650 lift. The $800 or so for Ti intakes will be worth every penny if you want to spin the thing.

If you insist on steel valves, heads that back up @ .650, OEM or FAST manifold, hydraulic lifters, you need to resign yourself to not a lot of power nor revs.

You REALLY need someone to design the whole engine, and get additional professional help on the valvetrain from someone who has BT,DT on LS7s.

I'm not in that business, but the potential problems pointed out above should be obvious to any good engine designer who has worked with LS7s. Honestly I can't recommend a designer given your (proposed) constraints.

I suggest that if you try to wing it and do an "internet engine" you will be disappointed and also considerably poorer.

I think Kevin's (WKMCD) L92/LS3 headed 427 is a better deal than what it looks like you are trying to do.

Sorry if this all sounds negative and disappointing. It was meant to be realistic.

Good luck!

Jon

You need to ask yourself some questions well before trying to pick out cam lobes. Here are a few thoughts:

What are your performance and driveability goals for the engine and vehicle?

How much money are you willing to spend overall? This will detrmine if you can meet your goals. Are you willing to change you goals/mind if what you want won't work or will be too costly?

If you want to spin 7500 (and make decent power somewhere near there), you need to realize that production/FAST intake manifolds aren't in the cards. Think "sheet metal" or a single plane. Lots of work, and lots of money to make 'em work.

Flinging around valves approaching 120 gm and the very heavy springs needed with them is a BIG challenge for hydraulic lifters, as is getting lots of air into an engine this size with intakes that back up before .650 lift. The $800 or so for Ti intakes will be worth every penny if you want to spin the thing.

If you insist on steel valves, heads that back up @ .650, OEM or FAST manifold, hydraulic lifters, you need to resign yourself to not a lot of power nor revs.

You REALLY need someone to design the whole engine, and get additional professional help on the valvetrain from someone who has BT,DT on LS7s.

I'm not in that business, but the potential problems pointed out above should be obvious to any good engine designer who has worked with LS7s. Honestly I can't recommend a designer given your (proposed) constraints.

I suggest that if you try to wing it and do an "internet engine" you will be disappointed and also considerably poorer.

I think Kevin's (WKMCD) L92/LS3 headed 427 is a better deal than what it looks like you are trying to do.

Sorry if this all sounds negative and disappointing. It was meant to be realistic.

Good luck!

Jon

#6

If I would have made a list of who I wanted to find this thread you guys would have been at the top, thanx for the insight! I've actually considered the marine lobes, heres a single post link to my original thoughts in my build thread that is now almost 3 years old (thread link in my sig).

https://ls1tech.com/forums/8228634-post45.html

Now I think that I might be able to get away with something a bit more aggressive. Thanx for lettming me know about EPS. I might have to give Geoff a call in the future.

The application is an endurance road racer. Power at 7500 rpm isn't really the main concern. I was actually thinking of a peak 6400-6600, but thought that it would be really benneficial if I could hold the revs to 7500 rpm on occasion if it made me faster out of a series of turns. I just want to be able to hold a gear a little longer if it helps my lap times.

I'd like to stick with the stock LS7 intake for now. If I ever get to the point with my driving that I can keep the car facing the right direction, I might eventually go individual throttle bodies and solid roller. But I think that even a 550-570 whp LS7 will be plenty for a long time. And this is regularly done in cam only LS7s below 7000 rpm.

I appreciate the "realism", better now than later. I'm very open to changing things around. My build has taken three years to this point. If it takes a bit longer to do it right then so be it even if that means taking a step backwards and buying some different valves. But with my proposed goals, I don't think that I'm too far out in left field... Or am I?

https://ls1tech.com/forums/8228634-post45.html

Now I think that I might be able to get away with something a bit more aggressive. Thanx for lettming me know about EPS. I might have to give Geoff a call in the future.

The application is an endurance road racer. Power at 7500 rpm isn't really the main concern. I was actually thinking of a peak 6400-6600, but thought that it would be really benneficial if I could hold the revs to 7500 rpm on occasion if it made me faster out of a series of turns. I just want to be able to hold a gear a little longer if it helps my lap times.

I'd like to stick with the stock LS7 intake for now. If I ever get to the point with my driving that I can keep the car facing the right direction, I might eventually go individual throttle bodies and solid roller. But I think that even a 550-570 whp LS7 will be plenty for a long time. And this is regularly done in cam only LS7s below 7000 rpm.

I appreciate the "realism", better now than later. I'm very open to changing things around. My build has taken three years to this point. If it takes a bit longer to do it right then so be it even if that means taking a step backwards and buying some different valves. But with my proposed goals, I don't think that I'm too far out in left field... Or am I?

#7

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

If I would have made a list of who I wanted to find this thread you guys would have been at the top, thanx for the insight! I've actually considered the marine lobes, heres a single post link to my original thoughts in my build thread that is now almost 3 years old (thread link in my sig).

https://ls1tech.com/forums/8228634-post45.html

Now I think that I might be able to get away with something a bit more aggressive. Thanx for lettming me know about EPS. I might have to give Geoff a call in the future.

The application is an endurance road racer. Power at 7500 rpm isn't really the main concern. I was actually thinking of a peak 6400-6600, but thought that it would be really benneficial if I could hold the revs to 7500 rpm on occasion if it made me faster out of a series of turns. I just want to be able to hold a gear a little longer if it helps my lap times.

I'd like to stick with the stock LS7 intake for now. If I ever get to the point with my driving that I can keep the car facing the right direction, I might eventually go individual throttle bodies and solid roller. But I think that even a 550-570 whp LS7 will be plenty for a long time. And this is regularly done in cam only LS7s below 7000 rpm.

I appreciate the "realism", better now than later. I'm very open to changing things around. My build has taken three years to this point. If it takes a bit longer to do it right then so be it even if that means taking a step backwards and buying some different valves. But with my proposed goals, I don't think that I'm too far out in left field... Or am I?

https://ls1tech.com/forums/8228634-post45.html

Now I think that I might be able to get away with something a bit more aggressive. Thanx for lettming me know about EPS. I might have to give Geoff a call in the future.

The application is an endurance road racer. Power at 7500 rpm isn't really the main concern. I was actually thinking of a peak 6400-6600, but thought that it would be really benneficial if I could hold the revs to 7500 rpm on occasion if it made me faster out of a series of turns. I just want to be able to hold a gear a little longer if it helps my lap times.

I'd like to stick with the stock LS7 intake for now. If I ever get to the point with my driving that I can keep the car facing the right direction, I might eventually go individual throttle bodies and solid roller. But I think that even a 550-570 whp LS7 will be plenty for a long time. And this is regularly done in cam only LS7s below 7000 rpm.

I appreciate the "realism", better now than later. I'm very open to changing things around. My build has taken three years to this point. If it takes a bit longer to do it right then so be it even if that means taking a step backwards and buying some different valves. But with my proposed goals, I don't think that I'm too far out in left field... Or am I?

Trending Topics

#8

Thanx for stepping in Shawn. Are you saying that with a gentle enough intake lobe profile that 7000+rpm is possible with hydraulic lifters, 118g valves, and 163/430lbs springs? If so do you think that the marine and or eps profiles count as gentle enough?

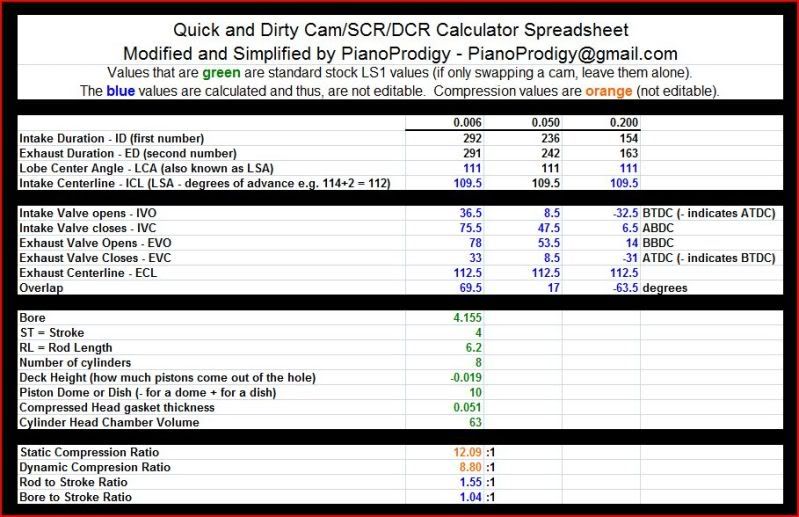

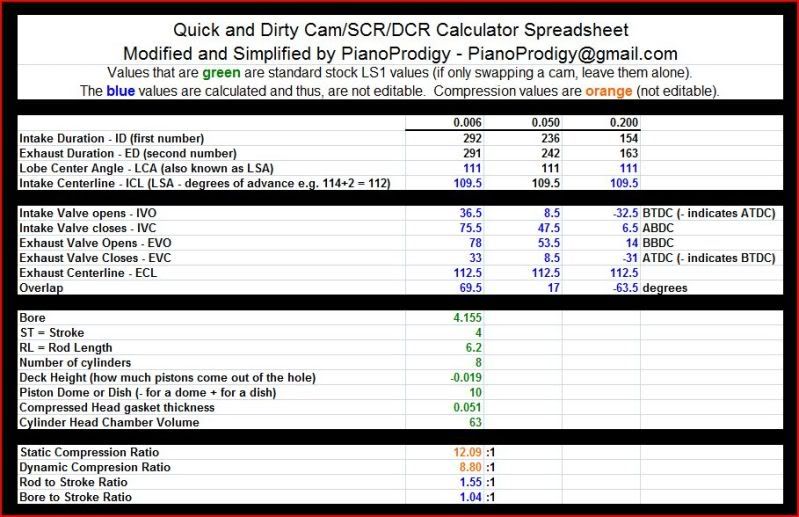

Here's a cam I spec'd for the build with a marine lobe intake and xer exhaust.

It may have a less aggressive split than you're used to seeing for LS7s, but I think those crazy splits are kinda BS, plus I'm running an amazing nascar built tri-y headers into expansion chambers, and a stock intake.

I plan on running custom pistons, so I can use whatever dome/dish I want. My heads were milled from the stock 70cc down to about 63cc. The katech torquer cam gives a stock LS7 a DCR of >9.0:1, and I'm feeling adventurous, so the above shoots for a DCR of 8.9 using a 10cc dish, and yes I think it'll work on 93 octane even with >20 deg of timing. Originally I was thinking about using a 20 degree overlap with an LSA of 109 to 110.5. But recently I've been hearing that tuning anything over about 14 degrees of overlap can get dicey. My old tuner highly reccomends an SD tune, so maybe the tighter LSA (20 degree overlap @ 0.0500") wouldn't be a problem?

-Dru

Here's a cam I spec'd for the build with a marine lobe intake and xer exhaust.

It may have a less aggressive split than you're used to seeing for LS7s, but I think those crazy splits are kinda BS, plus I'm running an amazing nascar built tri-y headers into expansion chambers, and a stock intake.

I plan on running custom pistons, so I can use whatever dome/dish I want. My heads were milled from the stock 70cc down to about 63cc. The katech torquer cam gives a stock LS7 a DCR of >9.0:1, and I'm feeling adventurous, so the above shoots for a DCR of 8.9 using a 10cc dish, and yes I think it'll work on 93 octane even with >20 deg of timing. Originally I was thinking about using a 20 degree overlap with an LSA of 109 to 110.5. But recently I've been hearing that tuning anything over about 14 degrees of overlap can get dicey. My old tuner highly reccomends an SD tune, so maybe the tighter LSA (20 degree overlap @ 0.0500") wouldn't be a problem?

-Dru

Last edited by GIGAPUNK; 03-09-2010 at 11:33 PM.

#11

TECH Addict

iTrader: (22)

Have you had your heads pressure tested??

Machining these heads to accept larger diameter springs can have serious consequences due to the casting shift.

Also, total lift is not the most limiting factor it is the ramp rate of the lobe. Given the heavy valves you have there are lobes out there that could theoretically have less total lift but would be almost uncontrollable given the amount of combined valve/spring weight you are dealng with.

My recommendation would be to call someone and tell them the constraints you have and let them take it from there.

Been down this road and paid royally for the Goddamned T-shirt that I still don't have.

Machining these heads to accept larger diameter springs can have serious consequences due to the casting shift.

Also, total lift is not the most limiting factor it is the ramp rate of the lobe. Given the heavy valves you have there are lobes out there that could theoretically have less total lift but would be almost uncontrollable given the amount of combined valve/spring weight you are dealng with.

My recommendation would be to call someone and tell them the constraints you have and let them take it from there.

Been down this road and paid royally for the Goddamned T-shirt that I still don't have.

#12

Richard at WCCH did the head inspection when they were new. I told him about my constraints and he told me about the problems relieving the valve pockets on the LS7, but said that he could do it safely on this set because he wasn't going very deep. These springs were his reccomendation. I have a lot of respect for Richard's know-how. I know what you're saying regarding ramp rates is true. The only reason I keep mentioning lobe lift as a limiting factor is that my springs are almost two years old, and newer designs seem to be designed for closer to 0.700" lift, while mine are only designed for upto 0.660".

#13

12 Second Club

Join Date: Mar 2006

Location: Sarasota, FL

Posts: 302

Likes: 0

Received 0 Likes

on

0 Posts

I wouldn't sweat trying to get THE perfect lobe. Pick one that looks good, then go one step milder.

Comp XER lobes have been in a LOT of hard-running LS motors. The XE lobes were the hot deal in the earlier days of LS-ness and are a notch milder. At the durations you're considering they max out at .630" w/1.8s. That seems pretty reasonable with those springs.

You might also look at some of the GMPP cams. They tend to be conservative (from a valve control POV) road race endurance grinds. Something like the Grand Am Cup Cam, pn 88958606: 239/251, .604 lift w/1.8. That cam has been in a ton of road race cars over the years. OTOH, if you want GM's recommendation for an LS7-based road racer, that's the Stage 3 cam, pn 88958723: 233/276, .630 lift.

I'm not an expert, and I don't play one on TV.

Comp XER lobes have been in a LOT of hard-running LS motors. The XE lobes were the hot deal in the earlier days of LS-ness and are a notch milder. At the durations you're considering they max out at .630" w/1.8s. That seems pretty reasonable with those springs.

You might also look at some of the GMPP cams. They tend to be conservative (from a valve control POV) road race endurance grinds. Something like the Grand Am Cup Cam, pn 88958606: 239/251, .604 lift w/1.8. That cam has been in a ton of road race cars over the years. OTOH, if you want GM's recommendation for an LS7-based road racer, that's the Stage 3 cam, pn 88958723: 233/276, .630 lift.

I'm not an expert, and I don't play one on TV.

#15

LS1 Tech Administrator

iTrader: (14)

Comp created these custom lobes for EPS. The are basically "endurance" versions of the newer LSL/LSR lobes from Comp. By endurance, I mean the acceleration and jerk are slowed down enough to allow very stable valve action at sustained, high rpm. The EPS lobes work especially well with higher ratio rockers like the 1.8s. All you have to do is contact Geoff Skinner at EPS to work something for your application. 225-751-8500.

__________________

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

#16

10 Second Club

iTrader: (15)

Join Date: Nov 2001

Location: St. Michael, MN.

Posts: 4,519

Likes: 0

Received 0 Likes

on

0 Posts

The $800 or so for Ti intakes will be worth every penny if you want to spin the thing.

Originally I was thinking about using a 20 degree overlap with an LSA of 109 to 110.5. But recently I've been hearing that tuning anything over about 14 degrees of overlap can get dicey.

All you have to do is contact Geoff Skinner at EPS to work something for your application. 225-751-8500.