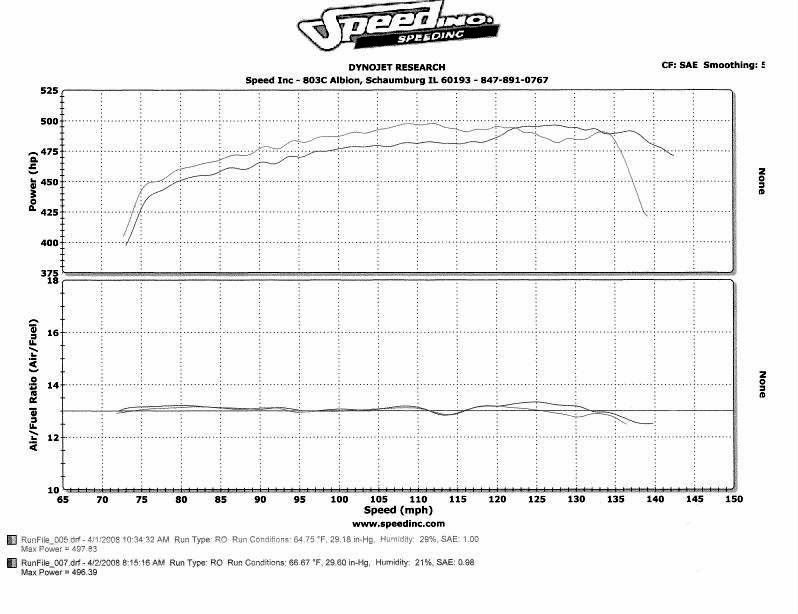

Who can explain this dyno graph?

#1

Ok this is my 402 LS2, 14-1, hyd roller (258/262 on a 110) Ported 243's, ported Vic jr and a 4150 TB. This is a drag setup 100%. One pull is with Comp pro mag 1.75 rockers and 3/8's pushrods that were.075 to long and binding on the heads (peaks at 6300 and makes alot more under the curve) . The other is with stock rockers and 5/16's pushrods with the proper preload of .060 on Caddy racing lifters. Last year with Comp R's, pro mag rockers with 5/16 pushrods and tired it peaked at 7100 and made 503rwhp. So how do I stop binding and correct pushrod length only to loose alot under the curve and 1 peak hp but gain 400 usable rpm?

I just want to thank Speed Inc for all there time and effort they put into getting the car sorted out. They even over nighted a set of pushrods for me and are awsome guys.

I just want to thank Speed Inc for all there time and effort they put into getting the car sorted out. They even over nighted a set of pushrods for me and are awsome guys.

#4

I think he is saying...

Why is it that AFTER fixing the binding issue and AFTER correcting the pushrod length on the motor...the motor seemed to make less power under the curve and only peaked @ 1hp more than previously. As a side note, using the correct pushrods allowed for 400rpm's more in the RPM band.

That is what I got out of the paragraph.

I don't know the answer to that. But I would tinker and tune a bit longer before I assume that the "fix" to my previous situation is hindering the ability of my motor.

Why is it that AFTER fixing the binding issue and AFTER correcting the pushrod length on the motor...the motor seemed to make less power under the curve and only peaked @ 1hp more than previously. As a side note, using the correct pushrods allowed for 400rpm's more in the RPM band.

That is what I got out of the paragraph.

I don't know the answer to that. But I would tinker and tune a bit longer before I assume that the "fix" to my previous situation is hindering the ability of my motor.

#7

Without a lot of A-B-A testing it going to be hard to put a finger on the cause. However as in most questions on the internet your going to get a lot of ideas.

The pushrod rubbing is a lot more of an issue than most people think. We had one that wasn't visable until we looked at the pushrods. It seems that as the pushrod flexed (they all do) it rubbed. Once we cured that problem our valve train was a lot happier at high RPM. What spring are you using? Is it enough? There are many factors that can effect the stability of the valve train. The 3/8 pushrods while heavier are the right choice. It's just a pain to get the clearance. Also the extra weight will need more spring pressure to keep it in control. Then the more spring pressure the more the pushrod will distort and you need more stiffness. It never ends. Each combination is different and there isn't one answer to every combination. There are guidelines that should get you close.

Good Luck!

The pushrod rubbing is a lot more of an issue than most people think. We had one that wasn't visable until we looked at the pushrods. It seems that as the pushrod flexed (they all do) it rubbed. Once we cured that problem our valve train was a lot happier at high RPM. What spring are you using? Is it enough? There are many factors that can effect the stability of the valve train. The 3/8 pushrods while heavier are the right choice. It's just a pain to get the clearance. Also the extra weight will need more spring pressure to keep it in control. Then the more spring pressure the more the pushrod will distort and you need more stiffness. It never ends. Each combination is different and there isn't one answer to every combination. There are guidelines that should get you close.

Good Luck!

Trending Topics

#8

My springs have 180/400 and have served me well. To be honest the only thing I can come up with is that these Caddy racing lifters just don't cut it. If they are not pumping up all the way the motor is not seeing 100% of the cam, with the .075 longer push rods instead of hanging the valve it takes up the slack until the springs and lifters can't handle it anymore. That is why I think I made 20 more rwhp under the curve with the wrong setup and 2 more peak hp 1200rpm sooner. The Caddy lifters are used with Titanium valves which I don't have and I doubt spring pressures this high. I am going back to comp R's and the 3/8's push rods and hope it fixes my problem.

Robin thank you for chiming in, at least someone did.

Robin thank you for chiming in, at least someone did.

#9

My $.02

#11

if the problem is the lifters, would a solid roller setup fix everything. i was told by weber racing that on any motor, a solid rller sould see more power. please let us know what happens and how you fix it because i am actually going to build myself a 402 at the same compression as you and have ls6 heads and victor jr already.

overall the lifter idea make sense which would have all the problems you are saying. when you ran it with stock length pushrods, do you get alot of valvetrain niose.

overall the lifter idea make sense which would have all the problems you are saying. when you ran it with stock length pushrods, do you get alot of valvetrain niose.